| View previous topic :: View next topic |

| Author |

Message |

JeffreyE

Member

Joined: Oct 27, 2012

Posts: 11

Location: Grand Rapids Michigan

|

Posted: Sat Dec 01, 2012 4:14 pm Post subject: Clutch Difficulties. Posted: Sat Dec 01, 2012 4:14 pm Post subject: Clutch Difficulties. |

|

|

Hello all,

I am fixing up a cj2a

and replaced the clutch pressure plate/friction disk with one I bought from kaiserwillys.com

Now the clutch will simply not disengage, I adjusted it way way back so I know I'm getting the throwout to travel (and can see it travel through the bellhousing).

Is it possible to install the friction disk backwards on a cj3a? I have not seen any articles and even though it was earlier in the build that I did it I recall thinking that it simply would not sit against the flywheel the wrong way... wouldnt come together...

Am I correct? Is it possible to install in reverse?

Thanks for your help. This is an amazing forum. |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16355

Location: Wisconsin

|

Posted: Sat Dec 01, 2012 8:09 pm Post subject: Posted: Sat Dec 01, 2012 8:09 pm Post subject: |

|

|

Two very common errors during installation often occur.

1-The disc is installed backwards and the high side of the center hub is dragging.

2-The clutch bellcrank cross shaft was installed backwards and doesn't have enough throw to release the disc. (look closely at the two arms on the cross shaft. The longer arm goes closest to the bell housing and the shorter arm goes towards the driver's frame rail.)

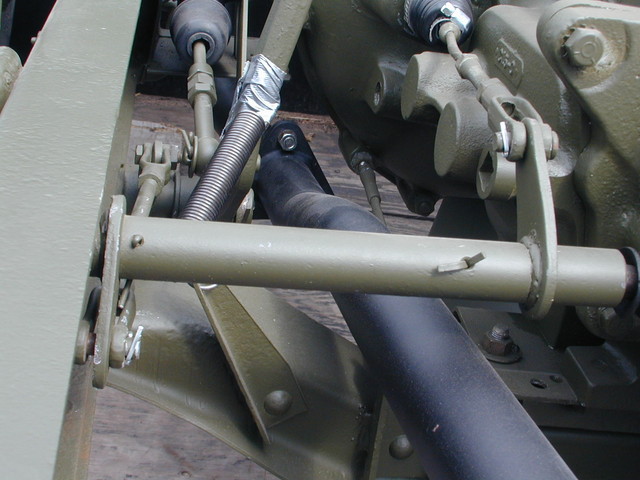

This is the clutch cross shaft. Little arm on the left and long arm on the right.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

JeffreyE

Member

Joined: Oct 27, 2012

Posts: 11

Location: Grand Rapids Michigan

|

Posted: Sun Dec 02, 2012 6:45 pm Post subject: Posted: Sun Dec 02, 2012 6:45 pm Post subject: |

|

|

If I posted a pic through the inspection cover could you tell

if the friction is on backwards?

I reallllly dont want to take it apart |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16355

Location: Wisconsin

|

Posted: Sun Dec 02, 2012 7:08 pm Post subject: Posted: Sun Dec 02, 2012 7:08 pm Post subject: |

|

|

Have you checked the cross shaft levers yet?

Am I correct in assuming the clutch worked before it was disassembled?

Exactly which parts did you replace in the clutch system?

If you have a friend depress the clutch pedal while you reach in through the inspection plate and see if you can get a finger tip on the edge of the clutch disc. Is there a gap between the disc and the flywheel or the disc and the pressure plate?

Please be sure to answer all 4 of these questions.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

JeffreyE

Member

Joined: Oct 27, 2012

Posts: 11

Location: Grand Rapids Michigan

|

Posted: Sun Dec 02, 2012 9:39 pm Post subject: Posted: Sun Dec 02, 2012 9:39 pm Post subject: |

|

|

clutch worked but was starting to slip as a result of a main oil

leak so I replaced the pressure plate/friction and flywheel bushing

... did not resurface though i know i should have

I will do your recommended tests tomorrow. you have been very helpful. |

|

| Back to top |

|

|

JeffreyE

Member

Joined: Oct 27, 2012

Posts: 11

Location: Grand Rapids Michigan

|

Posted: Tue Dec 04, 2012 5:26 pm Post subject: Posted: Tue Dec 04, 2012 5:26 pm Post subject: |

|

|

My clutch linkage looks fine and i tried the finger test but could not get any lift.

I happened to have an old flywheel / friction plate sitting around and took two pictures of what the configuration could be

Should it be like this:

Or should it be like this:

I think I need to take it all down anyway because there are some tcase/tranny leak issues I want to correct but I want to make sure its done right this time

Thanks![/url] |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16355

Location: Wisconsin

|

|

| Back to top |

|

|

JeffreyE

Member

Joined: Oct 27, 2012

Posts: 11

Location: Grand Rapids Michigan

|

Posted: Wed Dec 12, 2012 4:43 pm Post subject: Posted: Wed Dec 12, 2012 4:43 pm Post subject: |

|

|

cross shaft levers seems like it was the culpret but before i could figure it out I basically broke the cable pushing it down so hard.

It looked fine to me but i guess that little bit of leverage goes a long long way.

You have been awesome

thanks! |

|

| Back to top |

|

|

RICKG

Member

Joined: Aug 31, 2010

Posts: 1744

Location: SO IDAHO

|

Posted: Wed Dec 12, 2012 5:21 pm Post subject: Posted: Wed Dec 12, 2012 5:21 pm Post subject: |

|

|

Jeff, I've got a spare clutch cable around here somewheres-

PM me if you want it.

_________________

keep 'em rollin'

RICKG MC 51986 DOD 01-52, '50 CJ3a |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16355

Location: Wisconsin

|

|

| Back to top |

|

|

JeffreyE

Member

Joined: Oct 27, 2012

Posts: 11

Location: Grand Rapids Michigan

|

Posted: Wed Dec 12, 2012 6:03 pm Post subject: Posted: Wed Dec 12, 2012 6:03 pm Post subject: |

|

|

thanks rick and wes

I wont need another cable.

i think my brother has one at the farm

I can have

thanks for the offer though!

and thanks wes for the info |

|

| Back to top |

|

|

artificer

Member

Joined: Feb 16, 2007

Posts: 206

Location: Gold Coast Australia

|

Posted: Thu Dec 13, 2012 12:36 am Post subject: Posted: Thu Dec 13, 2012 12:36 am Post subject: |

|

|

When the clutch is off [& adjusted properly] the tabs on the cross shaft should be in near vertical positions. This will get enough travel & best leverage.

_________________

John GIBBINS

ASE Master Medium/Heavy Truck & Auto Technician 2002 USA

Licensed Motor Mechanic NSW # MVIC 49593 Current

YOU CAN'T TROUBLESHOOT WHAT YOU DON'T UNDERSTAND |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16355

Location: Wisconsin

|

Posted: Thu Dec 13, 2012 8:00 am Post subject: Posted: Thu Dec 13, 2012 8:00 am Post subject: |

|

|

To insure we don't introduce any confusion the only adjustment is at the cable end. The clutch cross shaft when installed correctly left side to the left and right side to the right it will be in the installed position and that position will be with the levers generally upward/downward about 20-30 degrees from vertical. Larger lever must be to the right.

Your goal is to adjust the cable until you have adequate free play at the top of the pedal travel. The final angle of the levers on the cross shaft is whatever that adjustment takes you to. Do not sacrifice the correct pedal free play to attain a more vertical positioning of the cross shaft levers.

To help make things tough for folks there are several different length cables and even a reproduction cross shaft with the ears angled incorrectly relative to each other.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

artificer

Member

Joined: Feb 16, 2007

Posts: 206

Location: Gold Coast Australia

|

Posted: Thu Dec 13, 2012 3:58 pm Post subject: Posted: Thu Dec 13, 2012 3:58 pm Post subject: |

|

|

| Quote: | | The final angle of the levers on the cross shaft is whatever that adjustment takes you to. |

Without arguing the point that statement is incorrect &/or a major over simplification.

The clutch operating mechanism is a system of "set" levers [& angles are part of this] to ensure application effort is correct.

If the "lever" tabs are not in their correct relative position such as the first picture below [or the tabs are reversed] one will have a much harder application effort [or softer if the cross shaft tabs are wrong way round].

The earlier picture [re-shown below] is not a properly adjusted clutch cross shaft, linkage & cable.

Obviously some components are incorrect & maladjusted especially the pedal to cross shaft rod fitted with clevis yokes [one adjustable]. That rod with clevis yokes is not original.

Shown below is what a cross shaft should look like when all components are matched to the correct vehicle model/type. The original question was "I am fixing up a cj2a" but the model is irrelevant in the overall scheme of things.

Done correctly the free play, will be correct

_________________

John GIBBINS

ASE Master Medium/Heavy Truck & Auto Technician 2002 USA

Licensed Motor Mechanic NSW # MVIC 49593 Current

YOU CAN'T TROUBLESHOOT WHAT YOU DON'T UNDERSTAND |

|

| Back to top |

|

|

JeffreyE

Member

Joined: Oct 27, 2012

Posts: 11

Location: Grand Rapids Michigan

|

Posted: Thu Dec 13, 2012 4:14 pm Post subject: Posted: Thu Dec 13, 2012 4:14 pm Post subject: |

|

|

Man.. I cant help but notice that my setup is not nearly as pretty or clean...

I have a ways to go.

In anycase for me myself the clutch is working great. |

|

| Back to top |

|

|

|