| View previous topic :: View next topic |

| Author |

Message |

Brumbach

Member

Joined: Jun 18, 2013

Posts: 178

|

Posted: Tue May 10, 2016 5:27 pm Post subject: M38 T90/Dana 18 Posted: Tue May 10, 2016 5:27 pm Post subject: M38 T90/Dana 18 |

|

|

| I've done the unpardonable, I've mixed bolts in the part cleaner bucket and am not certain which of them are used to bolt the tranny to the tc. Can anyone give their sizes? Thanks in advance. Bill |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16263

Location: Wisconsin

|

|

| Back to top |

|

|

Brumbach

Member

Joined: Jun 18, 2013

Posts: 178

|

Posted: Wed May 11, 2016 6:45 am Post subject: Posted: Wed May 11, 2016 6:45 am Post subject: |

|

|

| wesk wrote: | | Open your M38 ORD 9 SNL G-740 to page 198. One bolt is PN 120233 and the other four are PN 122138. The lock washers and flat washers are listed there as well. |

I believe you but how did you identify them? I see no reference or illustration to their application. |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16263

Location: Wisconsin

|

Posted: Wed May 11, 2016 8:17 am Post subject: Posted: Wed May 11, 2016 8:17 am Post subject: |

|

|

By their location in the parts list. I do not know your background but I have been using military manuals since 1966. You learn to feel your way around in them blindfolded. In the military we were told to read the introduction to a manual before using it. In this case read Paragraph 8 at the top of page 3 of the m38 ORD 9!

Many folks do not see what I see when I read a manual. In the M38's ORD 9 the 0800 section discusses the main unit and it's mounting hardware. If you run your finger down the 0800 column you see the mounting hardware for the case to the frame, then you see the case assembly finishes that level of the list. Then note the next group of hardware is indented to the right. This indicates it is either part of the assembly or attaches the assembly to it's mating part. Voila.

To take this a step further the experienced military mechanic knows he needs five 3/8"-16 course thread bolts with washer and lock washer. He knows the thickness of that area of both cases will need about 1" length so that tends to verify his results from the trip to the manual above.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

Brumbach

Member

Joined: Jun 18, 2013

Posts: 178

|

Posted: Wed May 11, 2016 10:52 am Post subject: Posted: Wed May 11, 2016 10:52 am Post subject: |

|

|

| wesk wrote: | By their location in the parts list. I do not know your background but I have been using military manuals since 1966. You learn to feel your way around in them blindfolded. In the military we were told to read the introduction to a manual before using it. In this case read Paragraph 8 at the top of page 3 of the m38 ORD 9!

Many folks do not see what I see when I read a manual. In the M38's ORD 9 the 0800 section discusses the main unit and it's mounting hardware. If you run your finger down the 0800 column you see the mounting hardware for the case to the frame, then you see the case assembly finishes that level of the list. Then note the next group of hardware is indented to the right. This indicates it is either part of the assembly or attaches the assembly to it's mating part. Voila.

To take this a step further the experienced military mechanic knows he needs five 3/8"-16 course thread bolts with washer and lock washer. He knows the thickness of that area of both cases will need about 1" length so that tends to verify his results from the trip to the manual above. |

I'm retired military and therefore have used military pubs quite a bit. Then again, I had hard copies and didn't use a computer to review. Thanks |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16263

Location: Wisconsin

|

|

| Back to top |

|

|

Brumbach

Member

Joined: Jun 18, 2013

Posts: 178

|

Posted: Wed May 11, 2016 12:55 pm Post subject: Posted: Wed May 11, 2016 12:55 pm Post subject: |

|

|

| wesk wrote: | I have been reading from a hard copy of the ORD 9 right here all along.

I retired 25 year ago and I don't care for operating with the computer PDF copies of manual. We provide those free for the folks on the web site hoping they'll realize the true value of having a real copy on the bench next to the jeep when working on it. |

I retired 21 years ago. While in the fleet, the closest we came to computers was microfiche and microfiche readers. Didn't care for them either. Agree, pubs are the only way to go. |

|

| Back to top |

|

|

Brumbach

Member

Joined: Jun 18, 2013

Posts: 178

|

Posted: Wed May 11, 2016 5:19 pm Post subject: Posted: Wed May 11, 2016 5:19 pm Post subject: |

|

|

| wesk wrote: | I have been reading from a hard copy of the ORD 9 right here all along.

I retired 25 year ago and I don't care for operating with the computer PDF copies of manual. We provide those free for the folks on the web site hoping they'll realize the true value of having a real copy on the bench next to the jeep when working on it. |

You don't happen to know which hole the shorter bolts goes to do you? |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16263

Location: Wisconsin

|

Posted: Wed May 11, 2016 10:06 pm Post subject: Posted: Wed May 11, 2016 10:06 pm Post subject: |

|

|

Now we can see where the tech writers were't the best guys to use to write the procedure for installation in TM 9-8012 page 235. Should have been written by someone that actually installed a transfer on a tranny! This idiot writes about using four 1" bolts and one 1 1/8" bolt. Backwards!!!

The tech writer for the M38A1 was a bit smarter. TM 9-8014 page 235 gets it right! The cases are joined using two 1 1/8" bolts at the top two holes from the rear of the transfer housing going forward into the tranny housing. Then install the single 1 " bolt from the front side of the tranny flange rearward into the transfer housing. Then the last two 1 1/8" bolts go in the remaining two holes going forward into the tranny housing.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

Brumbach

Member

Joined: Jun 18, 2013

Posts: 178

|

Posted: Thu May 12, 2016 9:40 am Post subject: Posted: Thu May 12, 2016 9:40 am Post subject: |

|

|

| wesk wrote: | Now we can see where the tech writers were't the best guys to use to write the procedure for installation in TM 9-8012 page 235. Should have been written by someone that actually installed a transfer on a tranny! This idiot writes about using four 1" bolts and one 1 1/8" bolt. Backwards!!!

The tech writer for the M38A1 was a bit smarter. TM 9-8014 page 235 gets it right! The cases are joined using two 1 1/8" bolts at the top two holes from the rear of the transfer housing going forward into the tranny housing. Then install the single 1 " bolt from the front side of the tranny flange rearward into the transfer housing. Then the last two 1 1/8" bolts go in the remaining two holes going forward into the tranny housing. |

A couple more questions if you don't mind. What is the torque spec for these bolts? I seem to call reading it was 30 ft lbs but want to make sure.

The second question regards the transfer input gear. Is the 7/16 " nut torqued to a specific spec or just moderately tightened? I assume the transmission is suppose to be in gear to secure the shaft while tightening it - am I right? |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16263

Location: Wisconsin

|

Posted: Thu May 12, 2016 10:59 am Post subject: Posted: Thu May 12, 2016 10:59 am Post subject: |

|

|

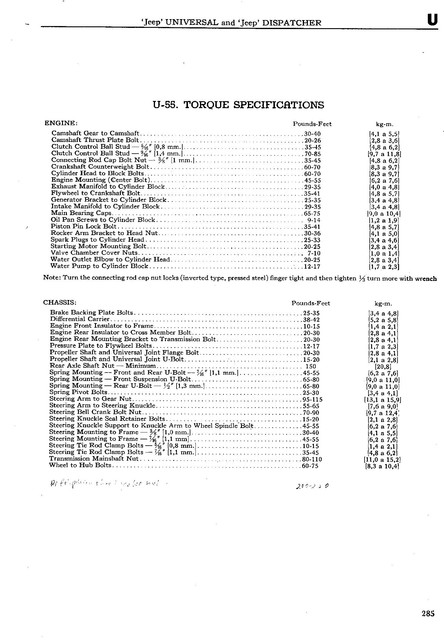

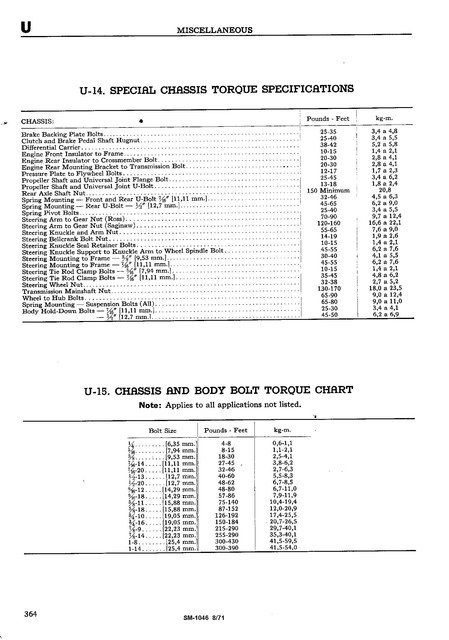

For torque specs when a specific torque is not listed for a specific task use a good quality standard torques chart for the appropriate grade hardware. Usually grade 5 & grade 8 charts will cover everything.

Use the grade 8 chart for the 3/8-16 threaded bolts (in tension) and the 7/8-16 nut (in shear).

The lack of torque charts in the older military TM's has always puzzled me. For this reason I have posted the torque charts from the Willys/Kaiser civvy manuals in my photo album.

From the early civvy flat fender manual SM-1002 Chapter U

From the later flat & round fender manual SM-1046 Chapter U

Note: Both of these manuals address the application specific torque for the tranny main shaft nut but the torques differ. As a rule the SM-1002 covers 46 to 58 and the SM-1046 covers 58-71.

There's a long 5 page photo series for the theories of torque applications:

http://www.willysmjeeps.com/v2/modules.php?set_albumName=album326&op=modload&name=gallery&file=index&include=view_album.php

As before the tech writer in the M38 TM 9-8012 lost it and called the 7/8-16 nut a 7/16 nut. The M38A1 TM 9-8014 manual tech writer was johnny on the spot with correct nut size and yes place tranny in gear during removal and installation of the nut.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

Thunderbird712

Member

Joined: Mar 26, 2012

Posts: 189

Location: Lexington Park Maryland (Southern Maryland)

|

Posted: Thu May 12, 2016 12:55 pm Post subject: Posted: Thu May 12, 2016 12:55 pm Post subject: |

|

|

| Quote: | | The tech writer for the M38A1 was a bit smarter. TM 9-8014 page 235 gets it right! The cases are joined using two 1 1/8" bolts at the top two holes from the rear of the transfer housing going forward into the tranny housing. Then install the single 1 " bolt from the front side of the tranny flange rearward into the transfer housing. Then the last two 1 1/8" bolts go in the remaining two holes going forward into the tranny housing. |

Had a question regarding this. I just finished up rebuilding my Tranny and TC and assembling them back to together. Using Novak's guide and willystech.com guide they both mentioned using the 1" bolt at the lower left corner going forward into the tranny housing as the 1 1/8" would interfere with the reverse idler gear. They both mention the use of two 1" bolts but no real reason why the 1" bolt is installed from the front side of the tranny into the TC.

I only had 1 1" bolt that I put on the lower left corner going forward into the Tranny. Not trying to correct Wes but rather just making sure I didn't miss something since I found a discrepancy with what I did during my rebuild and reading this post. I used the maintenance manual for reference on occasion but missed that quote from the manual until now.

_________________

TJ

53 M38A1 (project)

3/28/45 MB factory restoration project |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16263

Location: Wisconsin

|

Posted: Thu May 12, 2016 1:30 pm Post subject: Posted: Thu May 12, 2016 1:30 pm Post subject: |

|

|

TJ, that may be very true. However I haven't noticed any fit issues with the lower right bolt and since I use the old fashion cardboard with diagram and bolts stuck in it map when I take things apart with different length or size bolts I tend to usually get the same bolt back in the same hole.

To support your theory from the Novak & Willys Tech guides the CJ5 IPL shows two 1" bolts and three 1 1/8" bolts.

But to not support your theory the CJ3B IPL shows one 1" bolt and four 1 1/8's bolts as does the M38 & M38A1 ORD 9's.

With all this published dis-agreement over the bolt length counts it falls on the assembler to beware!

So in the end the best bet is to:

1-Layout varying length bolts in a diagram showing which hole they came out of.

2-Always check for any interference between bolts and moving parts when you install them.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

Thunderbird712

Member

Joined: Mar 26, 2012

Posts: 189

Location: Lexington Park Maryland (Southern Maryland)

|

Posted: Thu May 12, 2016 1:44 pm Post subject: Posted: Thu May 12, 2016 1:44 pm Post subject: |

|

|

Good points. When I disassembled I laid out the bolts so that I could reassemble back to how they were. At that time I didn't necessary notice that I had 1 shorter 1" bolt until I read about it in the guides and went to assemble. I cross checked all the parts books and noticed the discrepancies so then just assembled the bolts back to where they were taken out. I just missed the part you brought up from the TM so I wanted to ask. Thank you for the reply.

_________________

TJ

53 M38A1 (project)

3/28/45 MB factory restoration project |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16263

Location: Wisconsin

|

Posted: Sat May 14, 2016 10:44 pm Post subject: Posted: Sat May 14, 2016 10:44 pm Post subject: |

|

|

I received this question via a PM and it is a good question that should be answered here for all to learn from it.

| Quote: | According to your provided torque specs, this nut should be torqued 80-110 ft lbs. The tranny and transfer case are separated from the engine. The only way I can torque to this spec is to somehow secure the input shaft to enable that amount of torque on the nut. Alternatively, wait until the unit is reinstalled to the motor, although I'll bet the crankshaft will turn too. Am I misunderstanding something? I know the nut was not this tight when I separated the transmission from the transfer case and subsequently disassembled the transmission.

To make sure I'm not miss identifying components, I'm talking about the nut that holds the transmission mainshaft gear just inside of the transfer case. It would seem to me that such torque would bind this gear against the wall of the transfer case.

|

The nut is not torqued against the gear. It is torqued against the step in the shaft just before the spline are the gear is free to move fwd/aft on.

Every manual agrees the nut gets torqued to at LEAST 80 Ft Lbs. So at least start there. If it had a cotter pin I would suspect possibly a lower torque.

The whole idea of placing the tranny in 3rd and the trans in 4 Hi is to use the weight of the jeep and the engaged front & rear axles to hold the mainshaft still. It's not a big deal to leave the rear tranny/transfer cover plate off or just tacked on until you have the drive shafts connected.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

|