| View previous topic :: View next topic |

| Author |

Message |

southpw

Member

Joined: Jun 15, 2014

Posts: 268

Location: Cambridge, Ontario, Canada

|

Posted: Mon Sep 12, 2016 5:55 pm Post subject: Cylinder Head facing Posted: Mon Sep 12, 2016 5:55 pm Post subject: Cylinder Head facing |

|

|

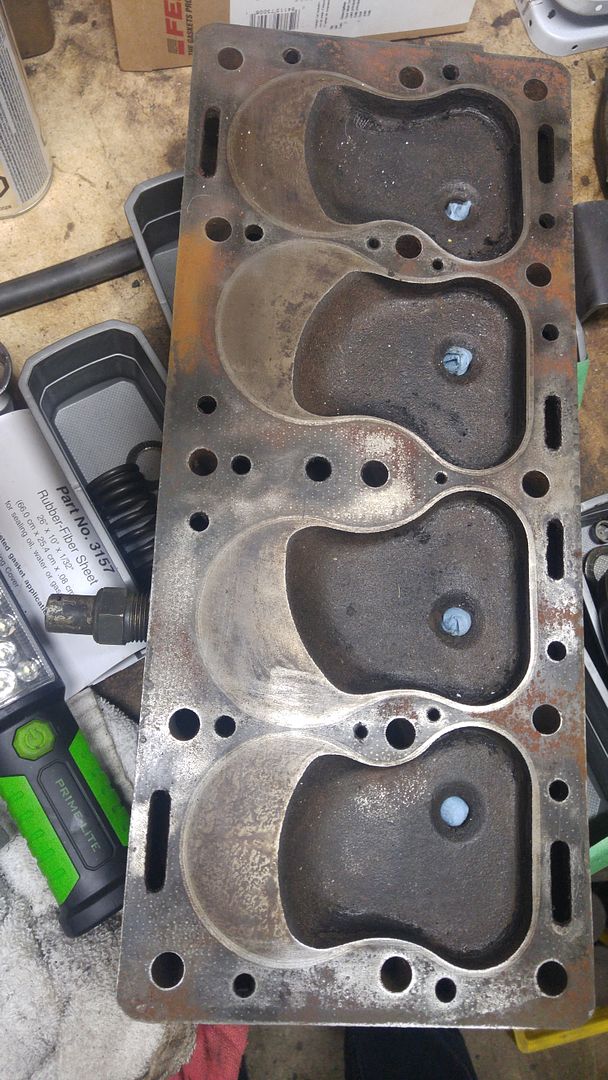

Good evening guys. I am having a real hard time removing all the gasket material on my head. When I think I have it all removed by using gasket remover and scraper, I let it sit, which then lets it dry completely and I see there is more material left and not a smooth surface. I have gone through 1 and a half spray cans of the gasket remover product.

So Im thinking of getting head faced but unsure how many times the head has already been faced. Is there a spec as to how shallow the bowl can get? I measure the depth at .460" currently.

Brad

_________________

1952 M38 project

Brad |

|

| Back to top |

|

|

4x4M38

Member

Joined: May 30, 2014

Posts: 3444

Location: Texas Hill Country

|

|

| Back to top |

|

|

southpw

Member

Joined: Jun 15, 2014

Posts: 268

Location: Cambridge, Ontario, Canada

|

Posted: Mon Sep 12, 2016 6:48 pm Post subject: Posted: Mon Sep 12, 2016 6:48 pm Post subject: |

|

|

Hi Brian. Those rust areas seems to be where the gasket remains. The other areas(where the dotted areas are) are the amooth areas but look like the gasket surface.

I would feel better if I could just resurface it without any issues. Unsure what original head thickness was and what the min thickness allowance is.

Brad

_________________

1952 M38 project

Brad |

|

| Back to top |

|

|

OKCM38CDN

Member

Joined: Feb 17, 2012

Posts: 530

Location: Del City, OK

|

Posted: Mon Sep 12, 2016 8:04 pm Post subject: Posted: Mon Sep 12, 2016 8:04 pm Post subject: |

|

|

Have you thought about using a BRASS wire brush on a grinder... brass should not hurt the head but take off the extra gunk...

_________________

Hal, KB1ZQ

TSGT, USAF (Ret)

1952 M-38 CDN CAR 52-31313

1952 M-100 Strick #104

1951 Willys Wagon (For Sale)

1954 Willys M38A1 201001205

Tornado Alley

Del City, OK |

|

| Back to top |

|

|

4x4M38

Member

Joined: May 30, 2014

Posts: 3444

Location: Texas Hill Country

|

|

| Back to top |

|

|

4x4M38

Member

Joined: May 30, 2014

Posts: 3444

Location: Texas Hill Country

|

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16241

Location: Wisconsin

|

|

| Back to top |

|

|

mbullism

Member

Joined: Jul 14, 2015

Posts: 36

|

Posted: Tue Sep 13, 2016 5:23 am Post subject: Posted: Tue Sep 13, 2016 5:23 am Post subject: |

|

|

I have seen discussions on head thickness vs compression ratio. Fairly certain it was measured from top of the rib to mating surface.

Will try and find a link-

ETA: this is not what I was thinking of, but see item #4

http://www.classicmilitaryautomotive.com/tag/l-134/

(it sure sounds like a lot... just passing it on) |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16241

Location: Wisconsin

|

Posted: Tue Sep 13, 2016 9:23 am Post subject: Posted: Tue Sep 13, 2016 9:23 am Post subject: |

|

|

As I said above, Part 2 / Par 4 of that link restates what I said, Over shaving of the head can result in too high a compression and valve interference. Also the info posted there is only what they assume to be original approximate factory head thickness as we do not have any factory published data available. I can hardly imagine that removing nearly a 1/4" from a 1/2" head could be considered an option. Also the head helps remove heat from the engine so the more meat you remove from the head the faster it will get hot and the less heat it will wick away from the engine.

My advice remains the same, take the head to your auto machinist and see what they have to say.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

southpw

Member

Joined: Jun 15, 2014

Posts: 268

Location: Cambridge, Ontario, Canada

|

Posted: Tue Sep 13, 2016 10:08 am Post subject: Posted: Tue Sep 13, 2016 10:08 am Post subject: |

|

|

Will do. Thanks for all the advice and info

Brad

_________________

1952 M38 project

Brad |

|

| Back to top |

|

|

mbullism

Member

Joined: Jul 14, 2015

Posts: 36

|

Posted: Tue Sep 13, 2016 1:15 pm Post subject: Posted: Tue Sep 13, 2016 1:15 pm Post subject: |

|

|

Took me a while to track this down... lol- work gets in the way:

| Quote: | | The standard 6.48:1 head dome volume was about 90.5 cc. Itís important to know if your head has already been milled (for reasons I outline later) before you have it milled. You can tell by measuring the thickness of the head from the mating surface to one of the machined head stud bosses on the corner of the head. A standard head will be around 2.1406 inches (plus or minus a few thousanths). If you want to go for the 7:1, then you want the total thickness of the head to be around 2.109 in., which should not be exceeded unless you know what you are doing. (Jim Allen) |

The quote above pulled from the links below, and the 2A page link has interesting photos comparing a 6.48 head with a supersonic head and an industrial low compression head.

http://www.thecj2apage.com/forums/going-supersonic-texas-version_topic27294.html

http://g503.com/forums/viewtopic.php?f=10&t=123939#p717838

YMMV...

Last edited by mbullism on Wed Sep 14, 2016 6:54 am; edited 1 time in total |

|

| Back to top |

|

|

southpw

Member

Joined: Jun 15, 2014

Posts: 268

Location: Cambridge, Ontario, Canada

|

Posted: Tue Sep 13, 2016 3:19 pm Post subject: Posted: Tue Sep 13, 2016 3:19 pm Post subject: |

|

|

Thanks for that info. My head thickness measures 2.095" so I may be best to just keep working this material off and not face it again.

_________________

1952 M38 project

Brad |

|

| Back to top |

|

|

4x4M38

Member

Joined: May 30, 2014

Posts: 3444

Location: Texas Hill Country

|

|

| Back to top |

|

|

mbullism

Member

Joined: Jul 14, 2015

Posts: 36

|

Posted: Tue Sep 13, 2016 7:30 pm Post subject: Posted: Tue Sep 13, 2016 7:30 pm Post subject: |

|

|

I'm not saying don't take it to a machine shop, only that you get as much info as possible to make an informed(?) decision is all...

On another note, x2 on the brass wire brush, just watch out for the gold colored wire wheels that are actually stiff steel. A magnet wont lie- |

|

| Back to top |

|

|

|