| View previous topic :: View next topic |

| Author |

Message |

davem201m38

Member

Joined: Jan 22, 2006

Posts: 429

Location: UK

|

Posted: Mon Aug 06, 2012 12:41 pm Post subject: Duel Circuit Master Cylinder problems Posted: Mon Aug 06, 2012 12:41 pm Post subject: Duel Circuit Master Cylinder problems |

|

|

Hi all,

Help.

Has anybody fitted a duel circuit master cylinder to the M38 before.

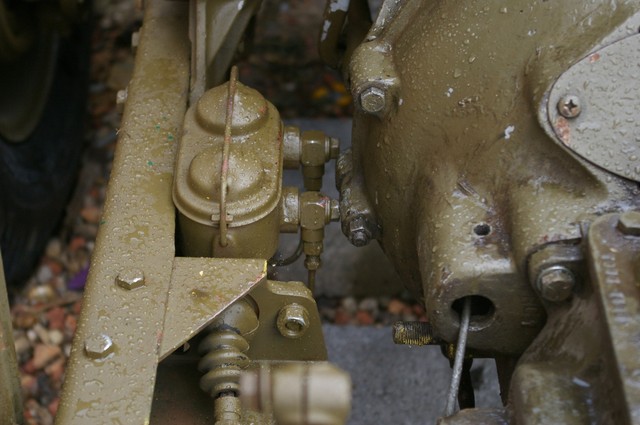

Here are some pics of my problems.

I bought the bracket and new master cylinder after a near miss with the original system.

Anyway, as you can see from the pictures the master cylinder is a bit more than a 'bolt in job'. It has been suggested that I need to loosen of all the mounts and haul the engine over to the passenger side and then tighten up all the mounting bolts. Well after a whole day with a 1.5 ton engine lift, two hydaulic jacks and three big blokes we still can't get anywhere like enough clearance between the brake line nuts and the bell housing.

I'm sure other people must have had the same problem before? The engine mountings are genuine NOS M38, the mounting points are not bent or distorted, the gearbox and transfer box sit perfectly in line on their mounts.

I'm at the point of trying to fabricate new mountings to move the whole engine slightly toward the passenger side.

Any ideas very gratefully recieved.

Thanks, Dave |

|

| Back to top |

|

|

Jim

Member

Joined: Apr 14, 2005

Posts: 196

Location: Van Buren, Arkansas

|

Posted: Mon Aug 06, 2012 2:32 pm Post subject: Posted: Mon Aug 06, 2012 2:32 pm Post subject: |

|

|

I'm way out of my depth on this, but what about a right

angle fitting without the bolt head or whatever that is that

is in the way? Perhaps with a thin nut on the shank between

the fitting and the brake unit to tighten everything up. Then

connect the brake line to that fitting.

Jim in Darkest Arkansas |

|

| Back to top |

|

|

artificer

Member

Joined: Feb 16, 2007

Posts: 206

Location: Gold Coast Australia

|

Posted: Mon Aug 06, 2012 4:38 pm Post subject: Posted: Mon Aug 06, 2012 4:38 pm Post subject: |

|

|

Those right angled fittings are only there to make things easier to bolt up.

In your situation I would be removing them & fabricating brake lines to fit directly into the master cylinder.

Most Hannefin Parker dealers have CUNIFER which is very easy to bend etc. & used by Volvo plus most other Europen manufacturers not looking for the cheapest brake lines.

You will need tight bends & this can be achieved by going to Pick & Pull & scavenging the wire spring material from an old brake line.

Just cut the fitting off the line @ one end & pull the spring away.

Set up your fitting/s on one end of your 2 lengths of new CUNIFER material....then slide the spring right up to the fitting which you have secured in a vyce & bend the pipe/s to the desired angle.

You can now remove the spring [or if you want leave it there] & fit the other brake line end/s.

_________________

John GIBBINS

ASE Master Medium/Heavy Truck & Auto Technician 2002 USA

Licensed Motor Mechanic NSW # MVIC 49593 Current

YOU CAN'T TROUBLESHOOT WHAT YOU DON'T UNDERSTAND |

|

| Back to top |

|

|

jimm

Member

Joined: Nov 01, 2011

Posts: 199

Location: Escondido, CA

|

Posted: Mon Aug 06, 2012 7:07 pm Post subject: Cunifer source Posted: Mon Aug 06, 2012 7:07 pm Post subject: Cunifer source |

|

|

If your nearest Parker Hannifin dealer doesn't stock Cunifer line, you can order it online from http://www.fedhillusa.com/. 6 ft, 12 ft, and 25 ft coils, and nuts to go with it.

_________________

Jim McKim

1952 M38 son-father project

Slowly turning rusty parts into OD parts |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16253

Location: Wisconsin

|

|

| Back to top |

|

|

artificer

Member

Joined: Feb 16, 2007

Posts: 206

Location: Gold Coast Australia

|

Posted: Tue Aug 07, 2012 1:21 am Post subject: Posted: Tue Aug 07, 2012 1:21 am Post subject: |

|

|

I believe they may Wes & all one probably needs to do is refit the little brass knock in flare fittings.

I have done this before on a dual Isuzu master cylinder I fitted to an MB[removed the brass flare fittings to fit the banjo type] so that is where I'm coming from.

But Dave won't know until he checks as you say.

_________________

John GIBBINS

ASE Master Medium/Heavy Truck & Auto Technician 2002 USA

Licensed Motor Mechanic NSW # MVIC 49593 Current

YOU CAN'T TROUBLESHOOT WHAT YOU DON'T UNDERSTAND |

|

| Back to top |

|

|

davem201m38

Member

Joined: Jan 22, 2006

Posts: 429

Location: UK

|

Posted: Tue Aug 07, 2012 1:45 am Post subject: Posted: Tue Aug 07, 2012 1:45 am Post subject: |

|

|

Hi, thanks for the replies.

I wasn't going to name the suppiler but it is a complete Herm kit, Master Cylinder and all.

The master cylinder is threaded to take those big adapters and those banjo's are supplied with the kit to save space.

I assume the kit supplier hasn't found a better way to get the 90 degree bend

I have not been able to find a suppiler in the UK that can come up with a better way (adapter) to get the 90 degree bend due to the size and type of threaded holes in the side of the master cylinder.

I was wondering if anybody had fitted this kit to an M38? looking at pictures I'm not sure clearances are the same for CJ3 etc. |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16253

Location: Wisconsin

|

|

| Back to top |

|

|

davem201m38

Member

Joined: Jan 22, 2006

Posts: 429

Location: UK

|

Posted: Tue Aug 07, 2012 1:55 pm Post subject: Posted: Tue Aug 07, 2012 1:55 pm Post subject: |

|

|

Ah, it might look that easy but it isn't.

Those cast bosses on the side of the master cylinder are the problem.

First you have to put a straight adapter into that boss, THEN you have to put the correct brake line nut into that adapter and then get the pipe curve in.

By the time you have the first hex of the adapter standing proud, then the second hex of the brake line nut you'er out as far as the last copper washer.

A simple elbow would be the fix but non of our parts shops can find one.

If somebody has managed that on an M38 with this master cylinder I'd love to see the picture. |

|

| Back to top |

|

|

capescw

Member

Joined: May 14, 2012

Posts: 150

Location: Milford CT

|

Posted: Tue Aug 07, 2012 7:08 pm Post subject: Alternative? Posted: Tue Aug 07, 2012 7:08 pm Post subject: Alternative? |

|

|

Just my 2 cents worth! If you machined the cylinder bosses slightly, and the same for the brass banjo fittings, would it then give you sufficient clearance?

Possibly some off the banjo bolt heads too!

_________________

"Frugality keeps me in the Game"

1952 M38 Project "Lazarus"

1951(?) M100 Trailer

1956-60 USAF Special Weapons Program

http://www.bill-capes.com/insanity - Updated 04/26/14 |

|

| Back to top |

|

|

davem201m38

Member

Joined: Jan 22, 2006

Posts: 429

Location: UK

|

Posted: Wed Aug 08, 2012 4:03 am Post subject: Posted: Wed Aug 08, 2012 4:03 am Post subject: |

|

|

Hi, thank you.

Again, I'd already gone down that route, here's the reply I got from the vendor.

The threads are 7/16" NF. If you will notice the special bolot has but shortened 3/16" and countersunk in the end for clearance for the residual valve. Good luck n another bolt as we make those because they are not available

The banjo is already machined to the minimum. The bosses are as small as possible already.

Had I realised this kit isn't the 'bolt in' option I'd have simply gone to the local bone yard or custom supplier and built my own instead of buying the kit.

The problem is those bosses and the internal thread size. The master cylinder supplied isn't the same one shown in the links.

If there are dozens of these kits in M38s I'd love to see a picture of this set up in another M38. I can bend Cunifer a tighter than the S bends pipe on the front of the MB brake back plate, and that bend still wouldn't get the clearance. |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16253

Location: Wisconsin

|

|

| Back to top |

|

|

davem201m38

Member

Joined: Jan 22, 2006

Posts: 429

Location: UK

|

Posted: Thu Aug 09, 2012 1:34 am Post subject: Posted: Thu Aug 09, 2012 1:34 am Post subject: |

|

|

Those banjo's are suppiled by Herm whom manufactures them for this application, they come with the whole kit. They are specially made short to fit, see the earlier post.

What is supllied does not match what is in those photo's on the CJ3 page.

http://www.hermtheoverdriveguy.com/id2.htm

"Banjo Bolt 90 Degree Adapter Kit - For dual reservoir Master Cylinder Conversions with limited space, please add my Banjo bolt kit. This banjo bolts and unions included in this kit add only 1" to the master cylinder width. Recommended for F-head installations. - $30"

If somebody has made THIS KIT fit, please show me.

There isn't an alternative that's why they are made and sold with that master cylinder.

I should have built this myself and not bought the kit. $250 for the kit plus shipping then 10% import duty tax, then 20% VAT tax on top of that then $20 handling charge on top of that. About $390!!

Using a bone yard or brand new master cylinder from the racing mods catalouge and buliding the bracket would have cost half a day and $60, we live we learn.

It's very simple, the master cylinder supllied with this kit is not fit for purpose. It can not be made to fit, it is too wide for even tight Cunifer bends because you need two inline fittings before you get the bend any pipe. It's junk.

CJ's of any age don't exist in our scrap yards. The only way to get the master cyclinder you say is to order another new one from the States, and I'm not sure I'd get what I asked for.[/i] |

|

| Back to top |

|

|

davem201m38

Member

Joined: Jan 22, 2006

Posts: 429

Location: UK

|

Posted: Thu Aug 09, 2012 2:35 pm Post subject: Posted: Thu Aug 09, 2012 2:35 pm Post subject: |

|

|

Update.

OK, we have made a 2 spacers to lift the fuel pump side of the engine 1 inch.

We have moved the genny side engine mount up 1/2 an inch.

We have lifted the transfer box and gearbox by 3/4 inch to get enough clearance for this "Bolt in kit" to fit. We do now have some clearance.

However, the fan now catches on the shroud. The genuine NOS exhaust (ex Greek and still in US Army wrappings when it was new) is canted at the wrong angle. Bizzarly the badly bent pattern part exhaust is now a better fit......

The clutch cross shaft is clearly at the wrong angle, and probably didn't help with the clutch problem, but thats solved.

It remains to be seen it the PTO shaft will clear. |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16253

Location: Wisconsin

|

|

| Back to top |

|

|

|