| View previous topic :: View next topic |

| Author |

Message |

bl5211a

Member

Joined: Dec 28, 2006

Posts: 344

Location: NC

|

Posted: Sat Sep 14, 2013 9:59 pm Post subject: Torque - Transmission to bell housing Posted: Sat Sep 14, 2013 9:59 pm Post subject: Torque - Transmission to bell housing |

|

|

Hunting around for the correct torque for mounting the transmission to bell-housing (4 bolts).

1955 M170.

Thanks,

Brian

_________________

Brian

1955 M170

1940 BSA M20 |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16260

Location: Wisconsin

|

Posted: Sat Sep 14, 2013 10:59 pm Post subject: Posted: Sat Sep 14, 2013 10:59 pm Post subject: |

|

|

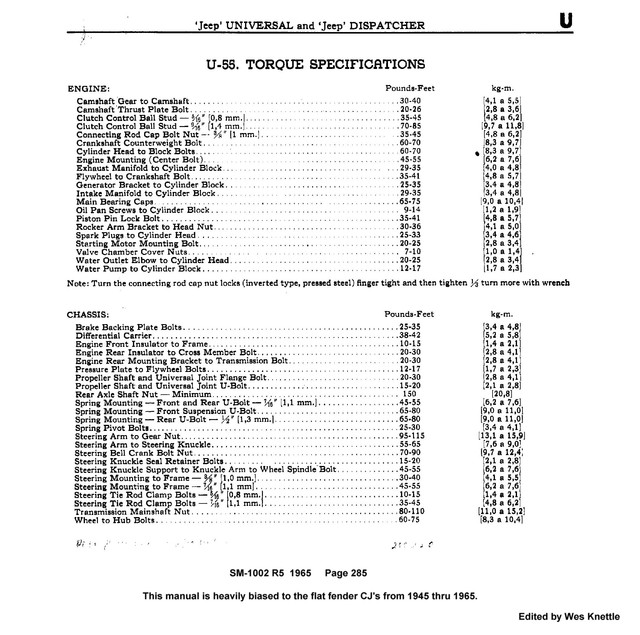

Torques not listed in the manuals for any specific applications are then selected from the standard torque chart using that type fastener and thread pitch / size.

I have the answers to this question loaded in my photo album.

This is the handiest list from the Willys/Kaiser SM1004 civvy CJ service manual.

There are dozens of Gade 5 through grade 8 automotive torque charts scattered all over the web. I have a couple loaded on my photo album.

http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php&page=9

Go there and review the standard industry toque data and formulas before selecting the torque you should use. If you are unsure of the bolt diameter, material and/or thread pitch the information is usually in the ORD 9 parts manual for your jeep.

Here's an example:

Keep in mind when using our photo albums the photos are stored normally in three sizes. The thumb nail, the intermediate size and the full size. When you click on a thumb nail the intermediate size pops in view. When you click on the intermediate size the full size pops into view.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

bl5211a

Member

Joined: Dec 28, 2006

Posts: 344

Location: NC

|

Posted: Sun Sep 15, 2013 7:13 am Post subject: Posted: Sun Sep 15, 2013 7:13 am Post subject: |

|

|

thanks - i printed these. I will use standard torque for grade 5

_________________

Brian

1955 M170

1940 BSA M20 |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16260

Location: Wisconsin

|

|

| Back to top |

|

|

bl5211a

Member

Joined: Dec 28, 2006

Posts: 344

Location: NC

|

Posted: Sun Sep 15, 2013 6:17 pm Post subject: Posted: Sun Sep 15, 2013 6:17 pm Post subject: |

|

|

What side should the dowell bolt head be on? The bell or the engine block?

_________________

Brian

1955 M170

1940 BSA M20 |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16260

Location: Wisconsin

|

Posted: Sun Sep 15, 2013 9:53 pm Post subject: Posted: Sun Sep 15, 2013 9:53 pm Post subject: |

|

|

All the 3/8" bolts accept the top two are installed from the front towards the rear. The bottom left has one bolt hole that is reserved for the stay cable and it's nut goes on the forward side of the bell adapter plate.

3/8" bolts are:

7371700 - 3/8-24NF-2x2 1/2" shouldered dowel bolts 2 ea.

123534 - 3/8-24NF-3x2 1/8" 3 ea Early bell, 4 ea late bell

123825 - 3/8-24NF-3x2 5/8" 2 ea

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php

Last edited by wesk on Tue Sep 17, 2013 10:34 pm; edited 1 time in total |

|

| Back to top |

|

|

bl5211a

Member

Joined: Dec 28, 2006

Posts: 344

Location: NC

|

Posted: Mon Sep 16, 2013 8:16 pm Post subject: Posted: Mon Sep 16, 2013 8:16 pm Post subject: |

|

|

Thanks for info

_________________

Brian

1955 M170

1940 BSA M20 |

|

| Back to top |

|

|

bl5211a

Member

Joined: Dec 28, 2006

Posts: 344

Location: NC

|

Posted: Tue Sep 17, 2013 4:04 pm Post subject: Posted: Tue Sep 17, 2013 4:04 pm Post subject: |

|

|

Hello :

Question about throwout bearing fork lubricant and input shaft lubricant.

Is anti-seize lubricant ok to use?

_________________

Brian

1955 M170

1940 BSA M20 |

|

| Back to top |

|

|

bl5211a

Member

Joined: Dec 28, 2006

Posts: 344

Location: NC

|

Posted: Tue Sep 17, 2013 4:07 pm Post subject: Posted: Tue Sep 17, 2013 4:07 pm Post subject: |

|

|

hey wes; i believe the photo you posted is m38, not m38a1/m170. aren't dowels on the side not the top.

_________________

Brian

1955 M170

1940 BSA M20 |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16260

Location: Wisconsin

|

|

| Back to top |

|

|

bl5211a

Member

Joined: Dec 28, 2006

Posts: 344

Location: NC

|

Posted: Tue Sep 17, 2013 9:00 pm Post subject: Posted: Tue Sep 17, 2013 9:00 pm Post subject: |

|

|

They fit the sides. Seems to be fine.

_________________

Brian

1955 M170

1940 BSA M20 |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16260

Location: Wisconsin

|

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16260

Location: Wisconsin

|

|

| Back to top |

|

|

bl5211a

Member

Joined: Dec 28, 2006

Posts: 344

Location: NC

|

Posted: Wed Sep 18, 2013 5:11 am Post subject: Posted: Wed Sep 18, 2013 5:11 am Post subject: |

|

|

I guess molly would be best for clutch fork pivot..?

_________________

Brian

1955 M170

1940 BSA M20 |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16260

Location: Wisconsin

|

|

| Back to top |

|

|

|