| View previous topic :: View next topic |

| Author |

Message |

joebuck

Member

Joined: Jul 16, 2013

Posts: 174

Location: oxford mississippi

|

Posted: Wed Nov 20, 2013 3:06 pm Post subject: Jimmyrigged My distributer! Guesses on Problem? Posted: Wed Nov 20, 2013 3:06 pm Post subject: Jimmyrigged My distributer! Guesses on Problem? |

|

|

I started a thread weeks ago about turning my distributor just a hair and it running better. Wes armed me with info on how to fix this. However now the jeep will not crank unless i hold the distributor with pressure as picture suggests. Furthermore the 7/16 bolt under the distrbutor is tight but will not hold the distributor in place so that it will run. I do not think its a timing issue but that bottom of distributor is not flush with block bracket? just the minute pressure or bump will cut jeep off. Could bottom of my distributor be rusted? the zip tie trick works well but i know it's not what i want for a long term fix. Should that distributor be rock tight against the block? mine isnt until i zip tie it.The motor like this runs exceptional ..... thanks for any help

[img] [/img] [/img]

_________________

1952 M38 |

|

| Back to top |

|

|

oilleaker1

Member

Joined: May 14, 2009

Posts: 971

Location: South Dakota

|

Posted: Wed Nov 20, 2013 3:20 pm Post subject: Posted: Wed Nov 20, 2013 3:20 pm Post subject: |

|

|

| I'd look inside the distributor for a short that grounds out the points or something touching intermittently. Compare yours with the Technical manual photos. I'm in the middle of my own strange problem. John |

|

| Back to top |

|

|

joebuck

Member

Joined: Jul 16, 2013

Posts: 174

Location: oxford mississippi

|

Posted: Wed Nov 20, 2013 5:25 pm Post subject: Posted: Wed Nov 20, 2013 5:25 pm Post subject: |

|

|

After looking through the manual, the wiggle is between the distrib base and the advance arm.. I have tight en the advance arm screw(bugger ti get to) but it will not lock the distrib base down snuggly to the collar. With the zip ties I can bind the base tight agaianst the collar and it cranks beautifully. If not , it will turn ove r and over and not crank.. scared to crank down on the advance arm attached screw to stripping. Whats is the demon!!

_________________

1952 M38 |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16256

Location: Wisconsin

|

|

| Back to top |

|

|

joebuck

Member

Joined: Jul 16, 2013

Posts: 174

Location: oxford mississippi

|

Posted: Thu Nov 21, 2013 6:55 am Post subject: Posted: Thu Nov 21, 2013 6:55 am Post subject: |

|

|

Thanks Wes !!!!! .... So if the gap in the spring clip is not offset to the tang, then this could stop a snug fit?

To remove distributor shaft, do I have to remove the water proof cover too? Or can I just undo spark wires and undo advance arm screw and it will pull out whole distrib, coil , cover , shaft in tact?

_________________

1952 M38 |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16256

Location: Wisconsin

|

Posted: Thu Nov 21, 2013 10:05 am Post subject: Posted: Thu Nov 21, 2013 10:05 am Post subject: |

|

|

| Quote: | | So if the gap in the spring clip is not offset to the tang, then this could stop a snug fit? |

That's not what I posted. You must not have read the writing in the photo.

It warns you that it is a common issue for the spring to stick in the top of the oil pump and stay there when you pull the distributor. Then if you don't notice it is missing you will re-install the distributor and the spring will not allow the tang all the way into the oil pump resulting in the issue you now have.

I then told you to pull the distributor and see if the spring is still on the shaft end. If it isn't I said fish it out of the oil pump, put it on the shaft and re-install and time the distributor.

(Nothing was said about where to orient the gap in the spring. Makes no differences where you orient the gap.)

The common method to remove and install the distributor is without the outer cap installed. Don't play with the plug wire cap nuts or they will start to wear, get loose and allow moisture in. The cap must be off so you can always see the rotor since you must always make sure it is pointing to the #1 wire position when installing the distributor.

You are following the published distributor installation and timing instructions in the manual?

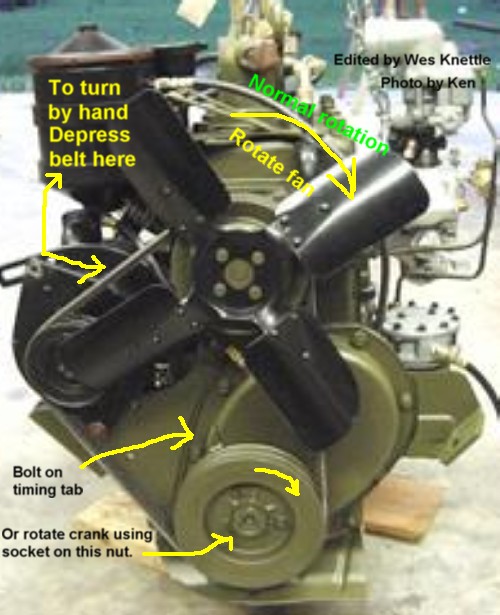

1-Plugs remove so engine turns by hand easy.

2-Rotating the crank clockwise when the crank pulley is viewed from the front, bring #1 piston at top of compression stroke (which is TDC top dead center).

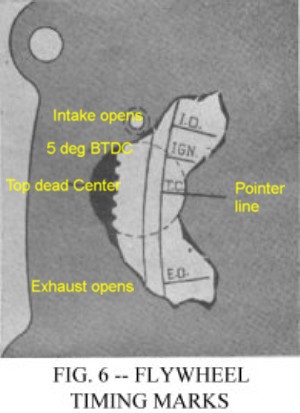

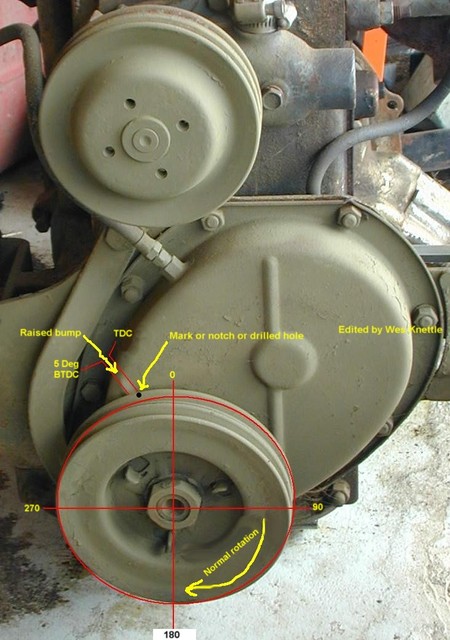

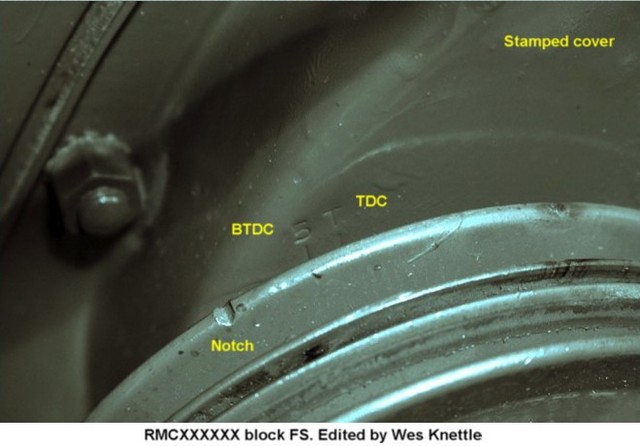

3-Then turn crank Counterclockwise the short distance from the TDC timing mark to the 5 Degrees BTDC mark. The type of marks vary based on year of production and civvy vs military engines. Over the years many changes occur. Here are examples of the common timing mark arrangements.

Early M38 flywheel timing marks

Early timing cover mounted timing marks.

Another early set of timing marks.

Later marks with separate timing tab bolted to the cover.

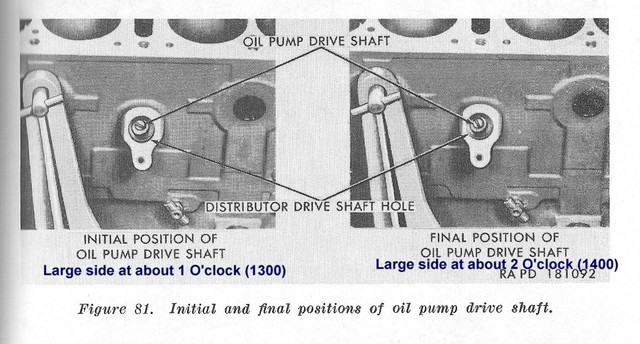

4-Confirm the oil pump shaft is oriented correctly. This is important. Although the timing can and often is done with the oil pump shaft not properly oriented often this will reduce the available rotational travel of the distributor body for timing purposes.

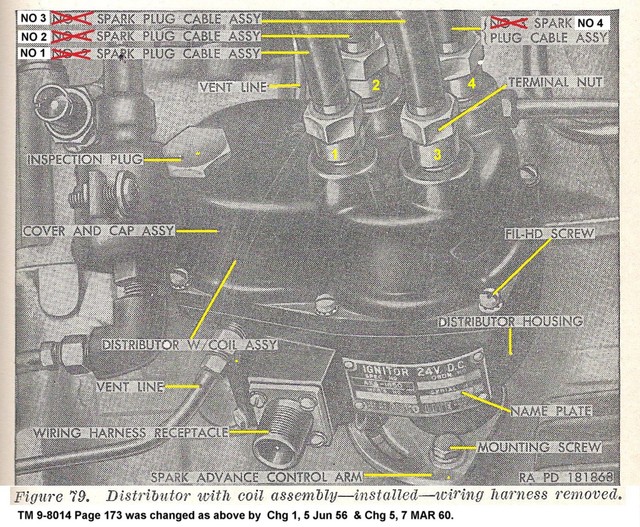

Warning, If you are using the M38A1 manual, TM 9-8014 page 173 that illustration of plug wire locations is wrong and was changed with a change notices several years after 8014 was printed.

The yellow numbers on the cap show the correct wire positions.

Then follow the published maintenance procedures.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16256

Location: Wisconsin

|

|

| Back to top |

|

|

joebuck

Member

Joined: Jul 16, 2013

Posts: 174

Location: oxford mississippi

|

Posted: Sun Sep 21, 2014 5:47 pm Post subject: Posted: Sun Sep 21, 2014 5:47 pm Post subject: |

|

|

Yes thanks Wesk. I started back from the beginning and checked plugs firing and found a plug that wasn't. So I bought a new distributor cap and she has been purring for a year now. Thanks

_________________

1952 M38 |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16256

Location: Wisconsin

|

|

| Back to top |

|

|

joebuck

Member

Joined: Jul 16, 2013

Posts: 174

Location: oxford mississippi

|

Posted: Wed Sep 24, 2014 6:29 am Post subject: Posted: Wed Sep 24, 2014 6:29 am Post subject: |

|

|

It was just a faulty distributor. One of contacts was not supplying sufficient charge to a plug

_________________

1952 M38 |

|

| Back to top |

|

|

|