Hi guys, First post. I tried the search funtion, reviewed the first few pages of results with no luck.

Getting ready to pull the brakes off the M. Have service manul on the way, but wanted to get my tools lined up. The jeep is at my family ranch about 4 hrs away and there arent many parts stores around there.

Question:

What size is the Axle nut?

Do I need to get a thin wall socket to remove or will a standard socket work?

I have:

-Hub Puller

-BFH

-Beer

-Cigs

-PB Blaster

-Torch

-Extensive vocabulary of explicits

Any other "special" tools not found in a typicall toolbox?

Clint

Leander TX

First post - 51 M38 axle nut size..... 2 1/16"???

Moderators: TomM, Moderator, wesk

- 51_M38_Tex

- Member

- Posts: 15

- Joined: Thu Sep 01, 2011 6:00 pm

- Location: Houston, TX

Let's see.. Beer, Cigs, BFH sounds like youre covered.

You may have to back off the shoe tension to the drums

before pulling. The ORD9 is available in the downloads

and has exploded views of just about every assembly

on the vehicle. Print it out and keep it next to your Bible..

You may have to back off the shoe tension to the drums

before pulling. The ORD9 is available in the downloads

and has exploded views of just about every assembly

on the vehicle. Print it out and keep it next to your Bible..

keep 'em rollin'

RICKG MC 51986 DOD 01-52, '50 CJ3a

RICKG MC 51986 DOD 01-52, '50 CJ3a

While you are waiting on your paper copy manuals download the PDF copies we have loaded on the downloads page and start reading!

http://www.willysmjeeps.com/v2/modules. ... oad&cid=39

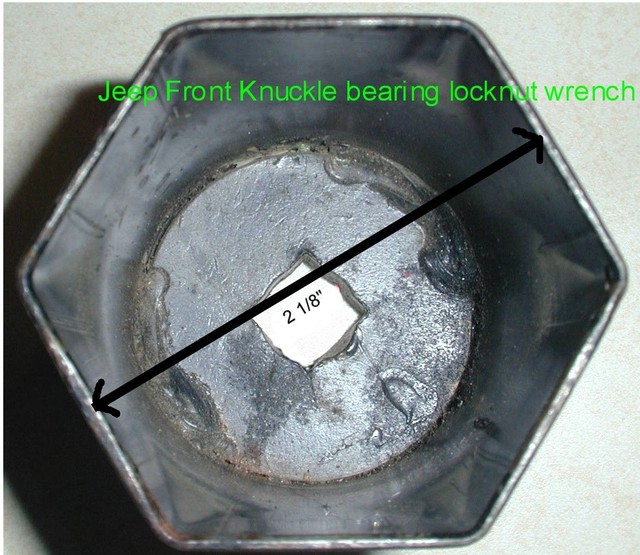

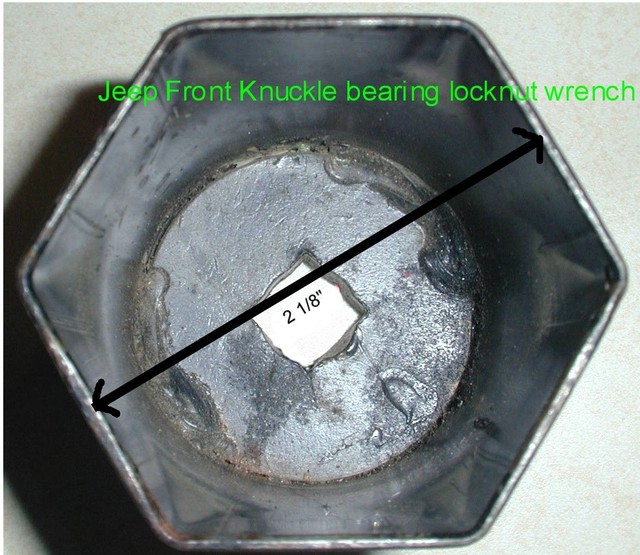

Since you are starting your resto get the hub nut wrench anyway. You will need it soon enough. I prefer to pull the front hub with the drum then it forces me to clean things up, check bearing condition and re-lube and adjust.

I have posted several photo albums to the photo page. Some are specialized like this one:

http://www.willysmjeeps.com/v2/modules. ... _album.php

Be sure to peruse them for tons of info not found in the written word!

There's also a ton of info in my personal photo albumL

http://www.willysmjeeps.com/v2/modules. ... _album.php

http://www.willysmjeeps.com/v2/modules. ... oad&cid=39

Since you are starting your resto get the hub nut wrench anyway. You will need it soon enough. I prefer to pull the front hub with the drum then it forces me to clean things up, check bearing condition and re-lube and adjust.

I have posted several photo albums to the photo page. Some are specialized like this one:

http://www.willysmjeeps.com/v2/modules. ... _album.php

Be sure to peruse them for tons of info not found in the written word!

There's also a ton of info in my personal photo albumL

http://www.willysmjeeps.com/v2/modules. ... _album.php

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

- 51_M38_Tex

- Member

- Posts: 15

- Joined: Thu Sep 01, 2011 6:00 pm

- Location: Houston, TX

Well I should do better research.

I got it running a few weeks ago after sitting in a barn of a family friend for about 10 years. I actually learned to drive a standard in this jeep. The man that owned it passed away and his wife is selling the farm and all the equipment. heard through the grapevine she wanted to sell it. She kew I wanted it and told me I could have it for $500. I picked it up the next weekend.

Put a battery in, hooked up a boat tank, filled the radiator, changed all the fluids, got pressure in the brakes and took off with a buddy and a cooler of beer.

Everything went great untill we went down a steep incline at a creek crossing. Stepped hard on the brakes, they grabbed and then !bang! no brakes. Good think it was in 4 low.

The front right drum broke radialy and the wheel cyl seal busted.

Were going to try and get everthing off, see what we can salvage and put an order in.

I got it running a few weeks ago after sitting in a barn of a family friend for about 10 years. I actually learned to drive a standard in this jeep. The man that owned it passed away and his wife is selling the farm and all the equipment. heard through the grapevine she wanted to sell it. She kew I wanted it and told me I could have it for $500. I picked it up the next weekend.

Put a battery in, hooked up a boat tank, filled the radiator, changed all the fluids, got pressure in the brakes and took off with a buddy and a cooler of beer.

Everything went great untill we went down a steep incline at a creek crossing. Stepped hard on the brakes, they grabbed and then !bang! no brakes. Good think it was in 4 low.

The front right drum broke radialy and the wheel cyl seal busted.

Were going to try and get everthing off, see what we can salvage and put an order in.

- RimfireJim

- Member

- Posts: 148

- Joined: Sun Feb 27, 2011 6:00 pm

- Location: Escondido, CA

Whoo! That must have been exciting!

The three screws Rick_L mentioned can be buggers to remove. They are slotted flatheads, so not much to get a grip on. The slots can be mucked up from previous attempts, and the threads can be rusted. I used one of those hand held impact drivers that you hit with a hammer to break 'em loose on mine. A few good solid hits and they broke free and screwed right on out.

Add a brake adjuster tool to your list to back off the shoes per Rick G's comment.

And, above all else, remember that lug nuts on the left side are left hand thread (unless they've been changed by PO), or you'll be using up your quota of expletives just trying to get the wheels off!

The three screws Rick_L mentioned can be buggers to remove. They are slotted flatheads, so not much to get a grip on. The slots can be mucked up from previous attempts, and the threads can be rusted. I used one of those hand held impact drivers that you hit with a hammer to break 'em loose on mine. A few good solid hits and they broke free and screwed right on out.

Add a brake adjuster tool to your list to back off the shoes per Rick G's comment.

And, above all else, remember that lug nuts on the left side are left hand thread (unless they've been changed by PO), or you'll be using up your quota of expletives just trying to get the wheels off!

Jim M.

1952 M38 son-father project

Discovering more worn out parts, one assembly at a time

1952 M38 son-father project

Discovering more worn out parts, one assembly at a time

- 51_M38_Tex

- Member

- Posts: 15

- Joined: Thu Sep 01, 2011 6:00 pm

- Location: Houston, TX

Thanks for the advise.

Everything came off, it took most of the weekend, all the beer and all the choice words.

I dont think the thing ever had a brake job. One of the driver side wheel studs was already snapped by the PO. Turning the lugs in the correct direction allowed for easy removal. All of the drum set screws were jacked up so they had to be drilled.

The odo shows 14K, but who knows when the spedo cable was unhooked. There was no matterial left on any of the shoes, the wheel cyl are shot, drums are shot, master cyl shot, soft line shot.

Everything came off, it took most of the weekend, all the beer and all the choice words.

I dont think the thing ever had a brake job. One of the driver side wheel studs was already snapped by the PO. Turning the lugs in the correct direction allowed for easy removal. All of the drum set screws were jacked up so they had to be drilled.

The odo shows 14K, but who knows when the spedo cable was unhooked. There was no matterial left on any of the shoes, the wheel cyl are shot, drums are shot, master cyl shot, soft line shot.

I changed all of mine to right wheel studs and nuts. No screwing up on the future.

Odo's are very unreliable for mileage. The military kept a record of OD changes but the vehicle records are destroyed when the jeep goes surplus.

A true 10 to 15 thousand mile M38 or M38A1 would be a real treat. But the mileage can never be confirmed.

Odo's are very unreliable for mileage. The military kept a record of OD changes but the vehicle records are destroyed when the jeep goes surplus.

A true 10 to 15 thousand mile M38 or M38A1 would be a real treat. But the mileage can never be confirmed.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php