OH, I didn't realize that there was an adapter in there. I hadn't gotten that far into the system yet and hadn't looked at it closely. Thanks for pointing that out!

So you're saying that mine should NOT have metal tube going through the dash?? An all rubber hose arrangement would certainly be easier! But I wonder where that tube in mine came from? FWIW I found two other pieces of bent metal tubing just laying inside the engine compartment and I've yet to figure what they're for either! Mine seems to have all of the tubing that's supposed to be there even though some are cut up and/or disconnected, so I don't any idea what the extra pieces are for.

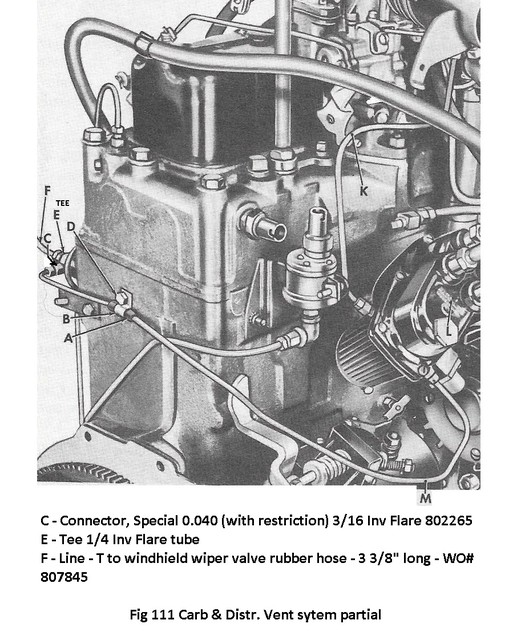

You can see where I made the item C a bit more visible.

The ORD 9 SNL G-758 covers the vent system in great detail in section 0304.5 starting with the illustration Fig 03-8 (pg 70-71) and parts listings (pg 86-92). The TM 9-8015-1 has a complete 11 page Chapter #6 that covers this vent system in great detail. All this for a system that was factory installed for only the first 13, 358 M38A1's built. Then the Army told Willys to discontinue the installation of the system as a cost saving measure. So less than 11% of all the M38A1's came with the factory underwater ventilating system. They are MD10001 (the first M38A1) thru MD23359 (Sep. 1952)!

Absolutely rubber from the tip of the tube I illustrated to the valve on the windshield. No telling who stuck the metal tubing in your glove box nor what it is for but it didn't get there at the Willys factory.

Keep in mind that although the Army abandoned the fording system for it's M38A1 the Marines did not. They ordered their own in the 60's with the kit and kitted the many thousands of A1's they inherited from the Army when the Army made the switch to the M151 1959 through 65.

Those old Army A1's that processed through the Marine Corp depots at Albany GA and Barstow CA 1959 thru 65 were refitted to the same standard as the Marine corp's new 1960 thru 64 contracts with Kaiser.