No oil to head, F134 (Solved)

Moderators: TomM, Moderator, wesk

No oil to head, F134 (Solved)

Hey once again guys,

I have a 1954 m38a1 with a 134f head motor.

Motor was freshly rebuild and new cam bearings installed. I have no oil coming to my head. Pulled the line and elbow, i am getting no oil flow from the passage.

I checked the passage below and i am getting oil flow there.

I was quite liberal with the engine assembly lube when i rebuilt the engine.

New cam bearings were also put in.

Is it possible that the lube has blocked the oil passage on the cam bearing?

Would motor flush help to clear it out?

or another possibility is to use one of the other oil passages and block off this passage?

I am getting 10 psi at idle and 20 psi at 2000 rpm cold.

With the engine hot it is producing 5 psi Idle and 20 psi at load.

I have a 1954 m38a1 with a 134f head motor.

Motor was freshly rebuild and new cam bearings installed. I have no oil coming to my head. Pulled the line and elbow, i am getting no oil flow from the passage.

I checked the passage below and i am getting oil flow there.

I was quite liberal with the engine assembly lube when i rebuilt the engine.

New cam bearings were also put in.

Is it possible that the lube has blocked the oil passage on the cam bearing?

Would motor flush help to clear it out?

or another possibility is to use one of the other oil passages and block off this passage?

I am getting 10 psi at idle and 20 psi at 2000 rpm cold.

With the engine hot it is producing 5 psi Idle and 20 psi at load.

Last edited by LTDan on Fri May 18, 2018 7:47 am, edited 1 time in total.

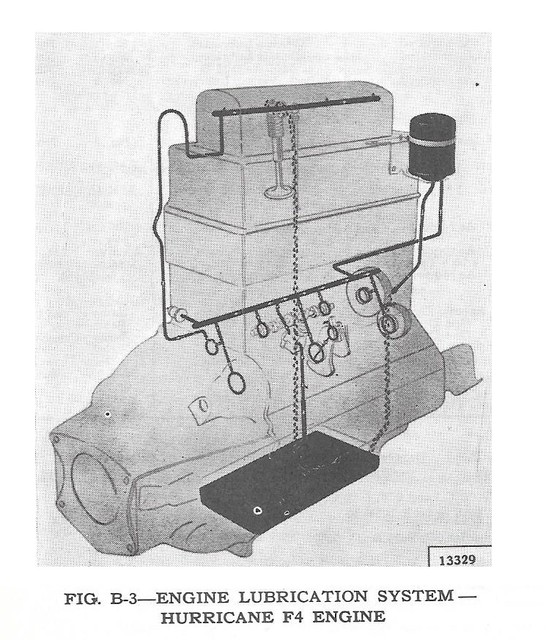

The f head valves and rocker are oiled from the #4 cam journal feed.

The F134 cam has 4 journals but uses only one bearing and it goes at the front #1 cam journal.

Many fresh Willys L & F 134 overhauls come out of the overhaul with low oil pressure. It is usually because we overlook two not so obvious places for wear beyond limits. The lifter bores and the #2 thru #4 cam journal block openings. There are oversize lifters that will allow you to solve a lifter bore wear issue but Willys decided not to support the back 3 cam journals with any bearings new or after field overhauls.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

So here is a thought wesk.

Would i be able to route from either the number 2 or 3 oil galley plug to the #4 cam journal, and route a line from either the number 2 or 3 passages up to my head?

I dropped the pan and the rear main bearing. Lower bearing is showing over heating and gouges in the surface, the crank shaft looks to be in good order still. As i cannot detect any marring on the surface of the crank shaft.

I am going to attempt to drop the crank tomorrow and inspect the upper bearing.

I am guessing that i have installed the rear main bearings wrong and have blocked the oil passage to the rear cam shaft journal.

Would i be able to route from either the number 2 or 3 oil galley plug to the #4 cam journal, and route a line from either the number 2 or 3 passages up to my head?

I dropped the pan and the rear main bearing. Lower bearing is showing over heating and gouges in the surface, the crank shaft looks to be in good order still. As i cannot detect any marring on the surface of the crank shaft.

I am going to attempt to drop the crank tomorrow and inspect the upper bearing.

I am guessing that i have installed the rear main bearings wrong and have blocked the oil passage to the rear cam shaft journal.

The rear main will not block oil to the top of the engine period.

What you are describing is a typical improper rear main seal installation that resulted in an overheating of the rear main bearing which will require a repair of the crank's rear bearing and rear main seal surfaces. Looks like you will also need to clean oil passageways.

Stop brain storming ways to work around the real problem. Find a shop or mechanic who knows the normal issues of the F134 and proceed with extreme caution this time.

Review this info: http://www.willysmjeeps.com/v2/modules. ... _album.php

What you are describing is a typical improper rear main seal installation that resulted in an overheating of the rear main bearing which will require a repair of the crank's rear bearing and rear main seal surfaces. Looks like you will also need to clean oil passageways.

Stop brain storming ways to work around the real problem. Find a shop or mechanic who knows the normal issues of the F134 and proceed with extreme caution this time.

Review this info: http://www.willysmjeeps.com/v2/modules. ... _album.php

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

Keep in mind that 1/2 century old equipment is seldom in it's original state with all original parts. Carefully ensure that all your parts are correct for your engine. An early crank does not do well using a late rear main seal. An early block also does not do well using a late rear main seal. You cannot mix and match unless you machine both parts to the same spec. What is the casting number on your block?

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

I found it! I found the problem.

When the machinist had put in new freeze plugs he used a bit of Black RTV to provide a better seal. Well guess what was in the oil passage junction between the camshaft and the crank shaft.

Yep a little tiny plug of silicon.

I thought i had cleared all of the oil passages while washing the block. I have since learned to slow down and refer back to the manual on all of the basic systems of the engines operation.

When the machinist had put in new freeze plugs he used a bit of Black RTV to provide a better seal. Well guess what was in the oil passage junction between the camshaft and the crank shaft.

Yep a little tiny plug of silicon.

I thought i had cleared all of the oil passages while washing the block. I have since learned to slow down and refer back to the manual on all of the basic systems of the engines operation.

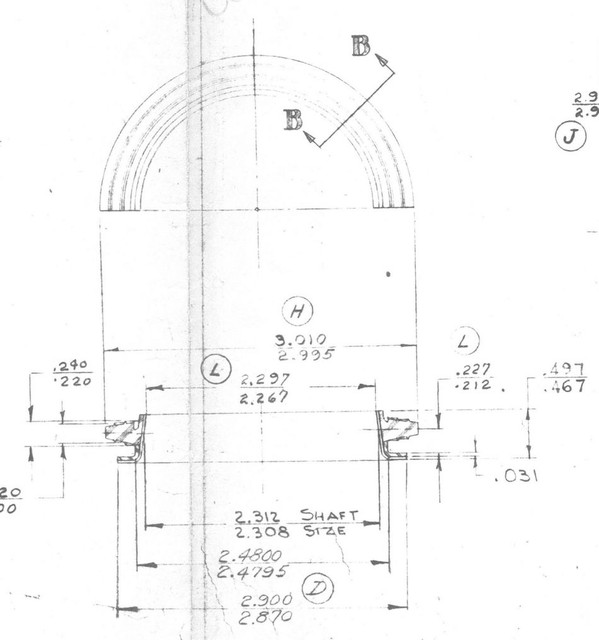

Wes thank you for bringing up the subject about the block. I knew about the crankshaft needing to be remachined to spec to accept the neoprene seal from scanning other posts but I guess I overlooked the part about the block needing to also be redone which only makes sense but I figured the seals were manufactured to accept the rope style section of the block glad I caught that one before I send out my block. The picture in your album labeled (800093 Rear Main Seal 1) would that be the dimensions/print for the shop to go by to remachine the block to accept the new style seal?

I'll try to link the picture from your album..........

I have not gotten to digging into my engine just yet so I do not know what style seals I have or if they have been converted but the 2 engines I have to choose from are block # 806279-W-13-D-AR are they early or late style?

Sorry LTDan to hijack your post but while on the subject I figured I'd ask, also good work on finding your problem.

As always thanks in advance.

I'll try to link the picture from your album..........

So are the later style blocks already machined to these dimensions?This is the url you must use to post the pic: http://willysmjeeps.com/v2/modules/gall ... .sized.jpg

You get this URL by right clicking on the image you wish to post IE the thumbnail, the mid-size or the large one. Then post that URL between the.

I have not gotten to digging into my engine just yet so I do not know what style seals I have or if they have been converted but the 2 engines I have to choose from are block # 806279-W-13-D-AR are they early or late style?

Sorry LTDan to hijack your post but while on the subject I figured I'd ask, also good work on finding your problem.

As always thanks in advance.

Jason

1953 M38A1

1953 M38A1

Its no problem bud, I am also talking with the machine shop now.Jason86 wrote:

Sorry LTDan to hijack your post but while on the subject I figured I'd ask, also good work on finding your problem.

My crank had to be welded and machined on the rear main sealing surface.

I believe they left too much weld on the new surface and I ended up crushing my neopreen rear main seals.

I had the rope seals on hand in the kit so i used those before i ran into the no oil to head issue.

I added more detail to the photo titles to answer your questions.

Keep in mind that the switch from rope seal to pre-formed seal did not happen during M38/M38A1/M170 production. If you have a MC, RMC, MD or RMD prefixed engine serial number your block left Willys set up for the pre-formed late seal. Your only worry would be weather the crank is original or an earlier substitute crank.

806279 is the later casting for the M38A1 and other Willys F134 applications. Your serial number ID's the original chassis installation.

Keep in mind that the switch from rope seal to pre-formed seal did not happen during M38/M38A1/M170 production. If you have a MC, RMC, MD or RMD prefixed engine serial number your block left Willys set up for the pre-formed late seal. Your only worry would be weather the crank is original or an earlier substitute crank.

806279 is the later casting for the M38A1 and other Willys F134 applications. Your serial number ID's the original chassis installation.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

Yep, You are reading it wrong!

If your jeep has a M38 engine in it (One with a MC or RMC prefixed serial) then that engine left Willys machined for the lip type modern seal.

If your jeep has a M38 engine in it (One with a MC or RMC prefixed serial) then that engine left Willys machined for the lip type modern seal.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php