M38A1 Battery 22NF Hold Downs

Moderators: TomM, Moderator, wesk

If they are a matched pair for the M38A1 modded by the 2nd MWO then they should have the one with the two angled brackets on the same rear side and one with the 2 angled brackets near one end. These are shown as the original stock hold downs in the my first photo.

If they are a matched pair for an M38 can you post photos of them?

If they are a matched pair for an M38 can you post photos of them?

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

Everyone - thanks for your help.

Wes - I wasn't even aware these documents existed. Thanks for sharing. Spent some time looking at your album to see what else is up there.

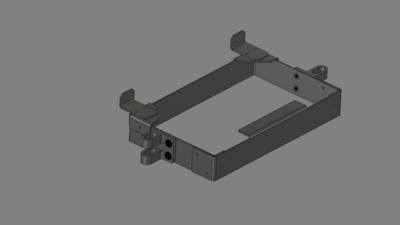

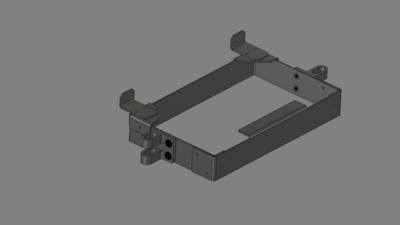

I spent some time looking at this, along with shots of other's solutions. Perhaps it's over the top, but I decided to design up a new hold down for the 22NF (or 51R) that is at least in the spirit of the original construction and design.

http://www.willysmjeeps.com/v2/modules. ... _photo.php

I don't have access to any tooling to make the u channel for the bolts, so I ended up doing a machined slot. If anyone else has any interest in parts like these, I can spread the tooling cost out and correct the design to be more representative.

A couple of questions: Anyone know what the sheet metal thickness / gage is of the original hold downs? Width of hold down?

Thanks!

Wes - I wasn't even aware these documents existed. Thanks for sharing. Spent some time looking at your album to see what else is up there.

I spent some time looking at this, along with shots of other's solutions. Perhaps it's over the top, but I decided to design up a new hold down for the 22NF (or 51R) that is at least in the spirit of the original construction and design.

http://www.willysmjeeps.com/v2/modules. ... _photo.php

I don't have access to any tooling to make the u channel for the bolts, so I ended up doing a machined slot. If anyone else has any interest in parts like these, I can spread the tooling cost out and correct the design to be more representative.

A couple of questions: Anyone know what the sheet metal thickness / gage is of the original hold downs? Width of hold down?

Thanks!

Bob Collins

1954 M38A1 MD79056

1954 M38A1 MD79056

The new angles are 3/4 x 3/4 x 1/8”

I’m sure there is a drawing or spec for the holddown

bracket steel, but I’m sure it’s 1/8” given the mass

of the battery. Maybe 3/4” width?

Note the hold down rod holes are part of the flat bar bracket.

There are two parts, that connect on the short sides.

The hold down openings are stamped into those pieces.

They are not separate.

I’m sure there is a drawing or spec for the holddown

bracket steel, but I’m sure it’s 1/8” given the mass

of the battery. Maybe 3/4” width?

Note the hold down rod holes are part of the flat bar bracket.

There are two parts, that connect on the short sides.

The hold down openings are stamped into those pieces.

They are not separate.

Thanks Brian.

I'm aware the new angle Wes showed in the documentation is 3/4 x 3/4 x 1/8. Like you mention, I am not 100% sure of the original bracket's width or gage / thickness.

Correct - I'm aware the openings are not separate parts - they are formed sheet of the weldment. I'm using a separate part above because I don't have tooling to make a U channel of that dimension.

I'll keep an eye out. Thanks again.

I'm aware the new angle Wes showed in the documentation is 3/4 x 3/4 x 1/8. Like you mention, I am not 100% sure of the original bracket's width or gage / thickness.

Correct - I'm aware the openings are not separate parts - they are formed sheet of the weldment. I'm using a separate part above because I don't have tooling to make a U channel of that dimension.

I'll keep an eye out. Thanks again.

Bob Collins

1954 M38A1 MD79056

1954 M38A1 MD79056

Here is a pic of one of the ones I have. I have almost thrown these out a number of times. The angle added is just that a length of angle iron.

'52 Dodge M37, '42 GPW, '48 FrankenJeep CJ2A/M38, '50 CJV-35(U), '51 M38, '42 WC-57 Command Car, '44 WC-51 Weapons , (2) M1941 Sperry 60" Anti-Aircraft Searchlights, John Deere M-gator, '44 White M3A1 Scout Car

I had a set of calipers laying right here, so:

The band that makes the upright is two pieces, the back piece is .860" high (this is the part that makes the U shapes for the hold downs too).

The front band with the angle reinforcement attached to it is .900" high.

Since these would have most likely sheared from sheets I would guess the original dimension was 7/8" for both.

Both are about .055" thick, so 17 gauge.

Hope this helps! You know the tool to make the "U" need not be much more complicated that the U you intent to machine, especially for material this thin.

The band that makes the upright is two pieces, the back piece is .860" high (this is the part that makes the U shapes for the hold downs too).

The front band with the angle reinforcement attached to it is .900" high.

Since these would have most likely sheared from sheets I would guess the original dimension was 7/8" for both.

Both are about .055" thick, so 17 gauge.

Hope this helps! You know the tool to make the "U" need not be much more complicated that the U you intent to machine, especially for material this thin.

'52 Dodge M37, '42 GPW, '48 FrankenJeep CJ2A/M38, '50 CJV-35(U), '51 M38, '42 WC-57 Command Car, '44 WC-51 Weapons , (2) M1941 Sperry 60" Anti-Aircraft Searchlights, John Deere M-gator, '44 White M3A1 Scout Car

Mark / Brian,

Thanks for your help! This is perfect.

Yes, I've been thinking about hand working it. I've leaned away from it a bit because I am able to use a CNC mill to make my proposed analogous part and thought this may end up looking better than my handiwork, but I may reconsider...

Thanks again both,

Bob

Thanks for your help! This is perfect.

Yes, I've been thinking about hand working it. I've leaned away from it a bit because I am able to use a CNC mill to make my proposed analogous part and thought this may end up looking better than my handiwork, but I may reconsider...

Thanks again both,

Bob

Bob Collins

1954 M38A1 MD79056

1954 M38A1 MD79056