M38 tub specs….looking for metal thickness for patchwork

Moderators: TomM, Moderator, wesk

M38 tub specs….looking for metal thickness for patchwork

Does anyone have metal thickness throughout the M38 tub? I am trying to make repairs throughout and want to use the correct gate in different areas. As always, thanks so much for the expertise.[/list]

-

RonD2

- Member

- Posts: 2065

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

Hi Bertram,

18 gauge (.0478 inch).

But if you don't want to take my word for it, see the second sentence of the description of the body in Chapter 12, paragraph 153, on page 163 of the Army TM9-1804B (July 1952), Power Train, Body, and Frame.

All the M38 Army manuals are free for download by using the "downloads" button above.

Good luck!

18 gauge (.0478 inch).

But if you don't want to take my word for it, see the second sentence of the description of the body in Chapter 12, paragraph 153, on page 163 of the Army TM9-1804B (July 1952), Power Train, Body, and Frame.

All the M38 Army manuals are free for download by using the "downloads" button above.

Good luck!

Ron D.

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

Nice call Ron!

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

-

RonD2

- Member

- Posts: 2065

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

Hi Brian,

Couldn't find that evidence in the manual --- maybe I missed it.

Am guessing, you measured an unmolested floor panel?

The manual does say "All major panels are 18 gauge..." which leaves out "minor" panels (whatever they be).

I'd think that floors qualify as "major", but who knows?

I didn't measure mine.

Quick search: http://willysmjeeps.com/v2/modules.php? ... loor+gauge

Couldn't find that evidence in the manual --- maybe I missed it.

Am guessing, you measured an unmolested floor panel?

The manual does say "All major panels are 18 gauge..." which leaves out "minor" panels (whatever they be).

I'd think that floors qualify as "major", but who knows?

I didn't measure mine.

Quick search: http://willysmjeeps.com/v2/modules.php? ... loor+gauge

Ron D.

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

-

rgmutchler

- Member

- Posts: 350

- Joined: Sat Sep 27, 2008 6:00 pm

- Location: Caldwell, Texas

When I was doing my body rebuild I found that the floor pan metal was 16ga. I don't remember where I found the information and at this late date don't know where I might have noted it. In any case I think that Brian is correct as to the floor being 16ga. Wish I could document it but right now I can't. Don't think I have muddied the water but I hope it is a little cloudy now. :}

Ralph

Ralph

I will assume the two purported 16 Gauge floors were measured by their owners with most likely a slide caliper gauge. Considering the floor is 1/3rd of the tub and both M38 (pg 163) & M38A1 (pg 238) manuals specify all major panels as 18 gauge and do to the large variances allowed in sheet steel production I believe we are either dealing with an incorrect/inaccurate gauge reading or a aftermarket replacement floor. Keep in mind that surface corrosion and /or paint will add thickness to your caliper readings that may slip you across the narrow line to the next gauge. Also using a slide gauge instead of a caliper/micrometer can also give you erroneous readings at the edge where cuts and wear tend to widen the thickness.

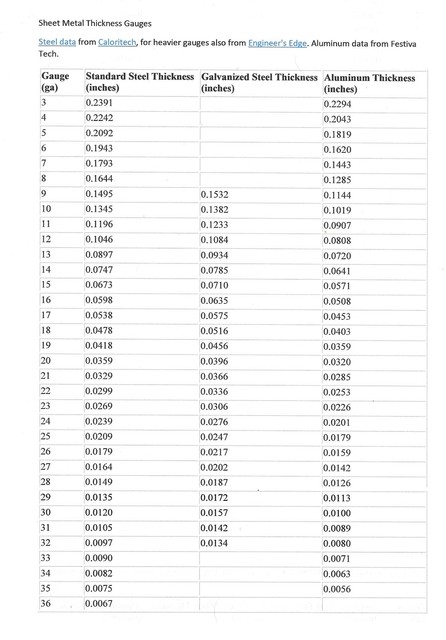

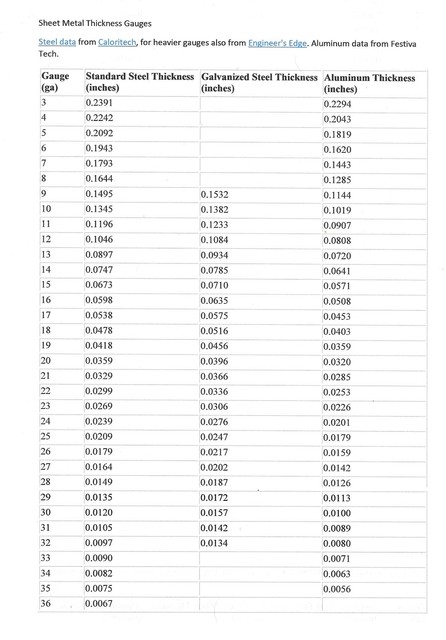

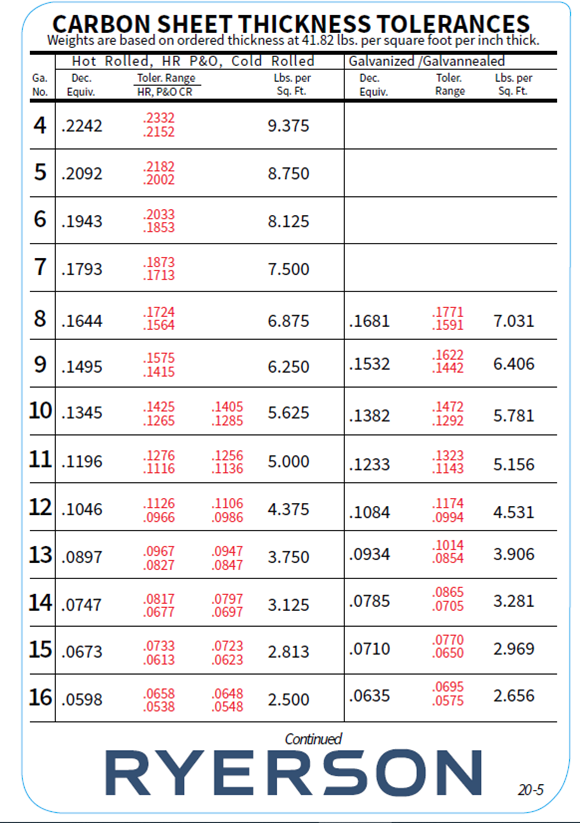

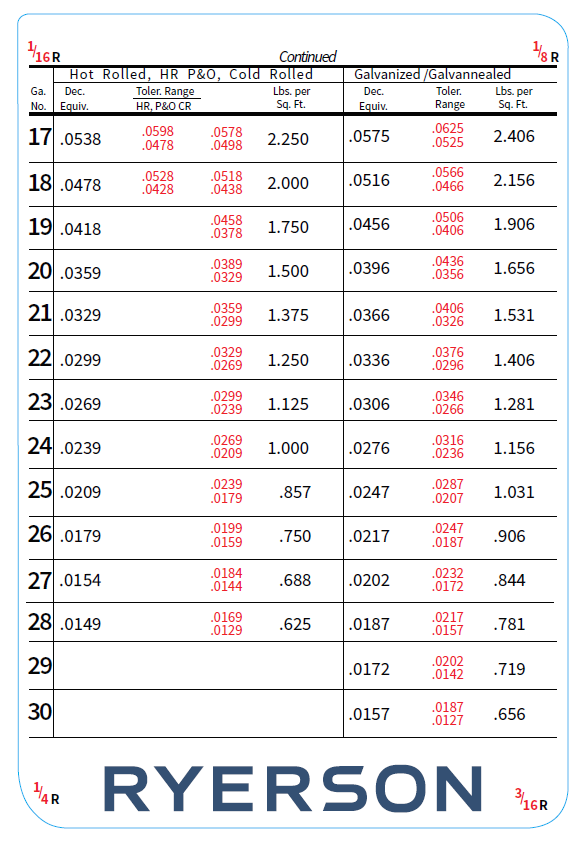

This is the target nominal thickness and only shows a single inch dimension reference for each gage.

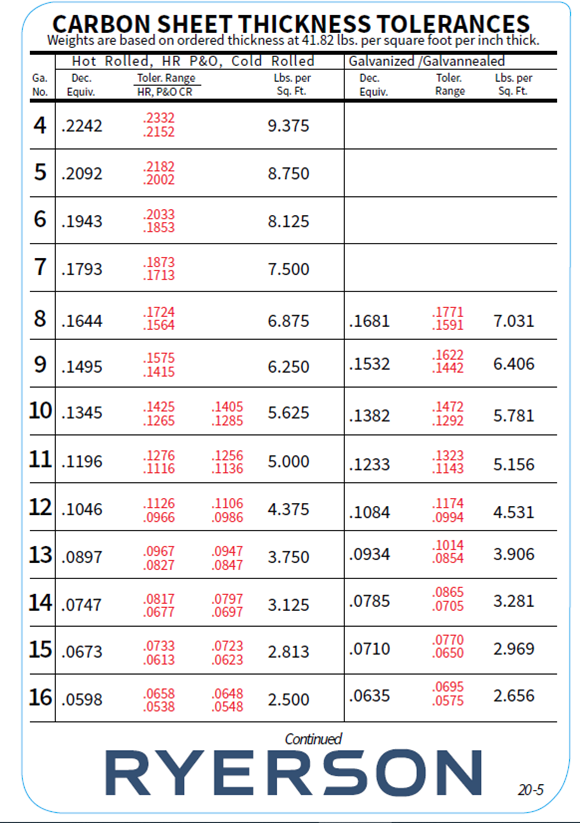

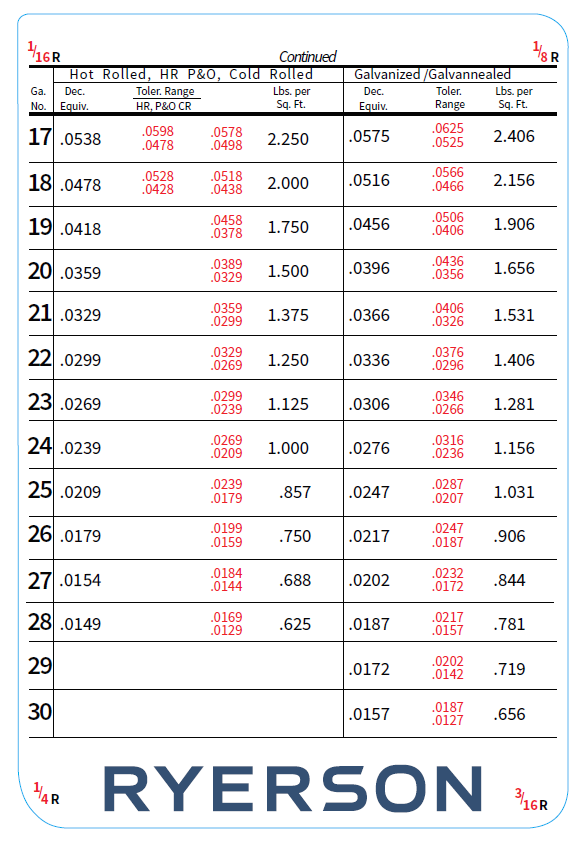

Here are the instructions for using the sheet carbon steel tolerance charts:

Here is a tolerance chart for Carbon steel sheet:

So, when asked for confirmation on sheet metal thickness always use the proper gauge tool and use the proper tolerance chart.

This is the target nominal thickness and only shows a single inch dimension reference for each gage.

Here are the instructions for using the sheet carbon steel tolerance charts:

09/18/2020

Steel Gauge Chart: The Why and How

Aluminum Grade Anatomy Selection Guide Stainless Steel

As the number goes up, the thickness goes down: this is the universal truth to reading a steel gauge chart. But truth be told, it isn’t quite clear as to why this is the case.

How thick is 14 gauge steel? What is thicker, 14 gauge or 16 gauge steel?

You have probably asked yourself such questions when trying to determine the thickness of your metal. This is why having a steel gauge chart as your guide can be invaluable.

Here is what you need to know: The numbers of a steel gauge chart typically range between 3-30. Yet those numbers do not indicate a specific dimensional value. Standard gauge sizes were developed based on the weight of the sheet for a given material and the equivalent thicknesses differ for each gauge size.

Why gauge?

Rather than inches or millimeters, steel is measured in terms of ‘gauge’. According to history, you can thank the 19th century British iron wire industry for this fact. During a period when no universal unit of thickness existed, gauge was adopted as the unit of measure. The journey from that time until now has some interesting points:

• The word ‘gauge’ is derived from and related to the French word ‘jauge’, meaning ‘result of measurement’.

• Gauge number sizes were the result of the process of wire drawing and the nature of iron as a substance.

• Gauges were measured and described in fractions of an inch during the 19th century.

• Craftsman found gauge to be convenient, thus further its adoption.

• At one point during the 20th century, the gauge was to be replaced with International System of Units—which ultimately did not occur.

How to read a steel gauge thickness chart

There two primary principles to keep in mind when using steel gauge charts:

1. Moving up or down a given steel gauge chart isn’t an equal move in decimal equivalent between numbers. Let’s take a 14-gauge stainless steel sheet, for example.

• A 14-gauge stainless steel sheet has a decimal equivalent of .0751.

• Moving down to a 13-gauge stainless steel sheet, the decimal equivalent is 0.0900

• Moving up to a 16-gauge stainless steel sheet, the decimal equivalent is 0.0595

2. The decimal equivalent of gauge numbers differs based on type of metal. Again, let’s use stainless steel as our example:

• A 14-gauge stainless steel sheet has a decimal equivalent of .0751.

• A 14-gauge carbon sheet has a decimal equivalent of 0.747.

This means that in order to ensure your material meets the correct dimensional requirements for your project, you must use the right steel gauge chart.

Here is a tolerance chart for Carbon steel sheet:

So, when asked for confirmation on sheet metal thickness always use the proper gauge tool and use the proper tolerance chart.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

-

rgmutchler

- Member

- Posts: 350

- Joined: Sat Sep 27, 2008 6:00 pm

- Location: Caldwell, Texas

Do you recall the dimension you accurately determined and the tool you used for that measurement?

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

I use 16 gauge for everything. Easier to get. Easier to weld. No one can tell the difference once it is in place.

M38 23100 June 51

M38 34523 Sep 51

M606/CJ3B 1964 Kaiser 57348 118458

M37B1 1963

Willys MB 1944

Ford GPW 1942

Dodge WC63 1943

Dodge Power Wagon WM300 1967

Plymouth Barracuda, 1973, 340 4 barrel

All ground up restored by me.

Lots of others.

M38 34523 Sep 51

M606/CJ3B 1964 Kaiser 57348 118458

M37B1 1963

Willys MB 1944

Ford GPW 1942

Dodge WC63 1943

Dodge Power Wagon WM300 1967

Plymouth Barracuda, 1973, 340 4 barrel

All ground up restored by me.

Lots of others.