flywheel advice

Moderators: TomM, Moderator, wesk

flywheel advice

When I removed the flywheel (129 tooth model) from my engine I did not mark it's position on the crankshaft. Will I encounter a problem when I put it back on if it is not put back in the exact spot?

-

RonD2

- Member

- Posts: 2065

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

Unless somebody in the past had it balanced, you shouldn't have a problem.

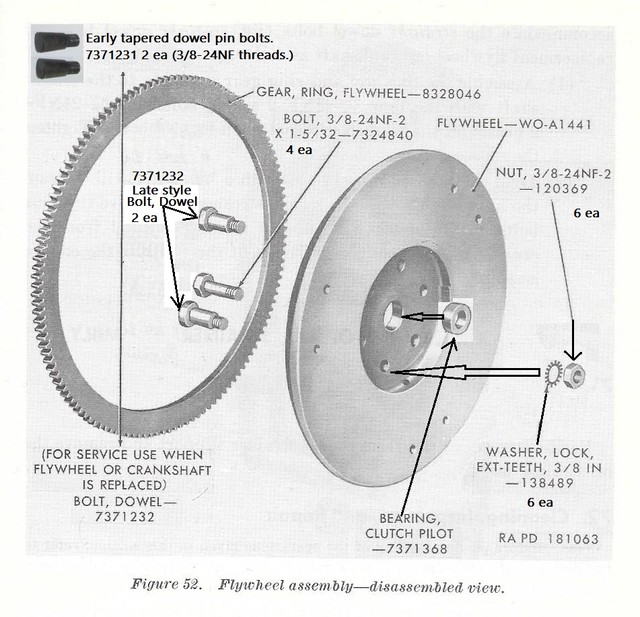

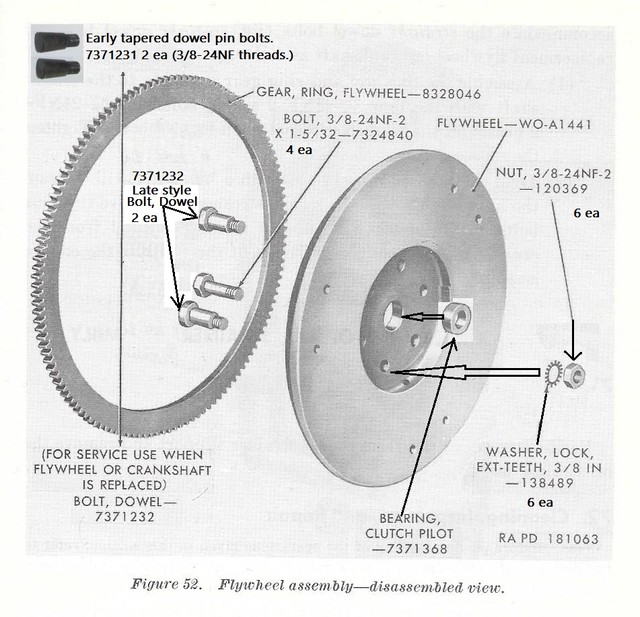

The 129 tooth flywheel should have 2 straight (not tapered) dowel bolts.

The manual gives directions and measurements to convert from tapered to straight dowel bolts.

Good time to replace the pilot bearing while you have it on the bench.

What did you decide about your 12 to 24 volt conversion question that you posted?

Good luck!

The 129 tooth flywheel should have 2 straight (not tapered) dowel bolts.

The manual gives directions and measurements to convert from tapered to straight dowel bolts.

Good time to replace the pilot bearing while you have it on the bench.

What did you decide about your 12 to 24 volt conversion question that you posted?

Good luck!

Ron D.

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

Hello Keith,

To avoid getting folks heading down the wrong track you should always include the model of your jeep in your post. Yes many things are the same but many are also no where near close. You can make it very easy by amending your signature element in your web site profile to include the first name you prefer to be addressed with and the make/model/year of your jeep.

My reply to your post below is based on the possibility your jeep could be one of 3 models this web site applies to.

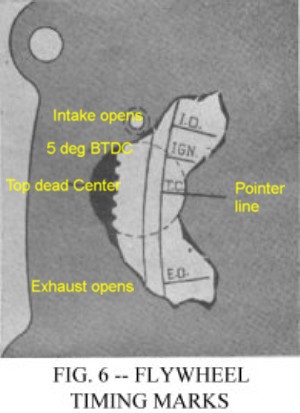

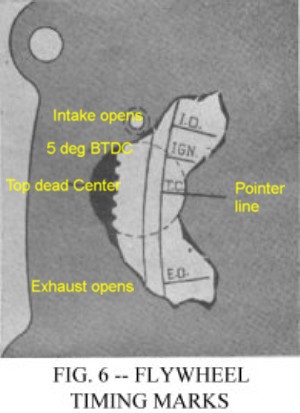

Your flywheel is suppose to have two locating dowells. Early were tapered and later are straight. It allows the flywheel to be installed two positions each 180 degrees off as opposed to the other. Makes no difference with later engines that do not use the flywheel markings for ignition timing however if you are working on an early engine with the small hole in the bell housing adapter plate for access to the flywheel timing marks then it does make a difference.

On another note if your engine has been balanced in the field it may become an issue on the flywheel positioning if the flywheel was used for the balance weight adjustments or if the flywheel is significantly out of balance.

Here's the early setup with the timing mark inspection window on the pass. side of the bell housing adapter plate:

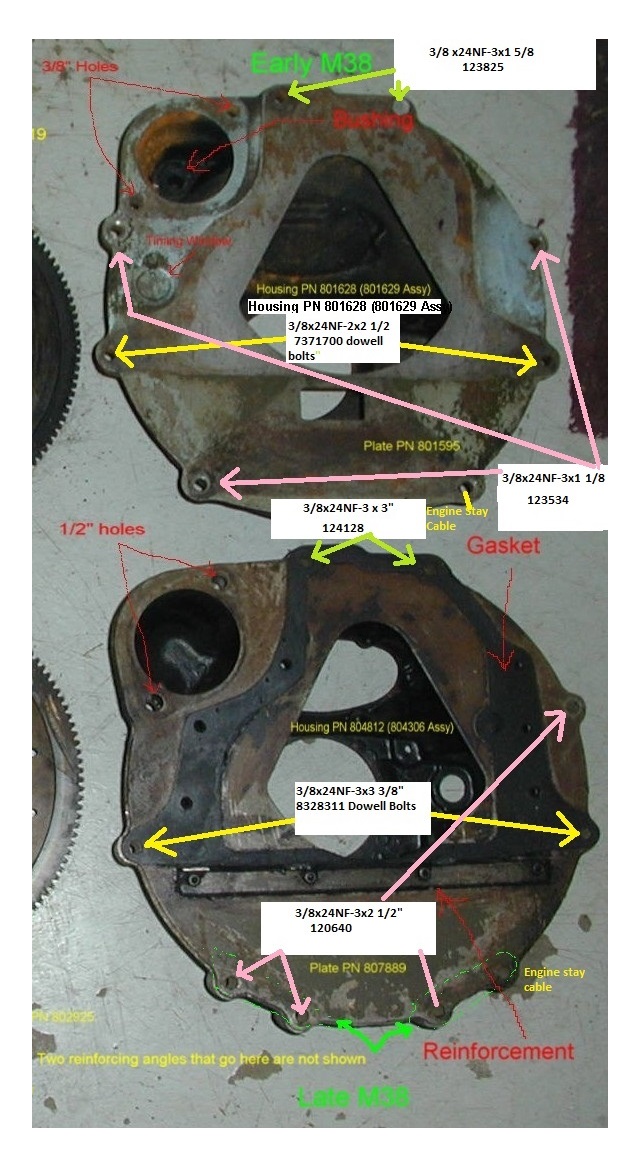

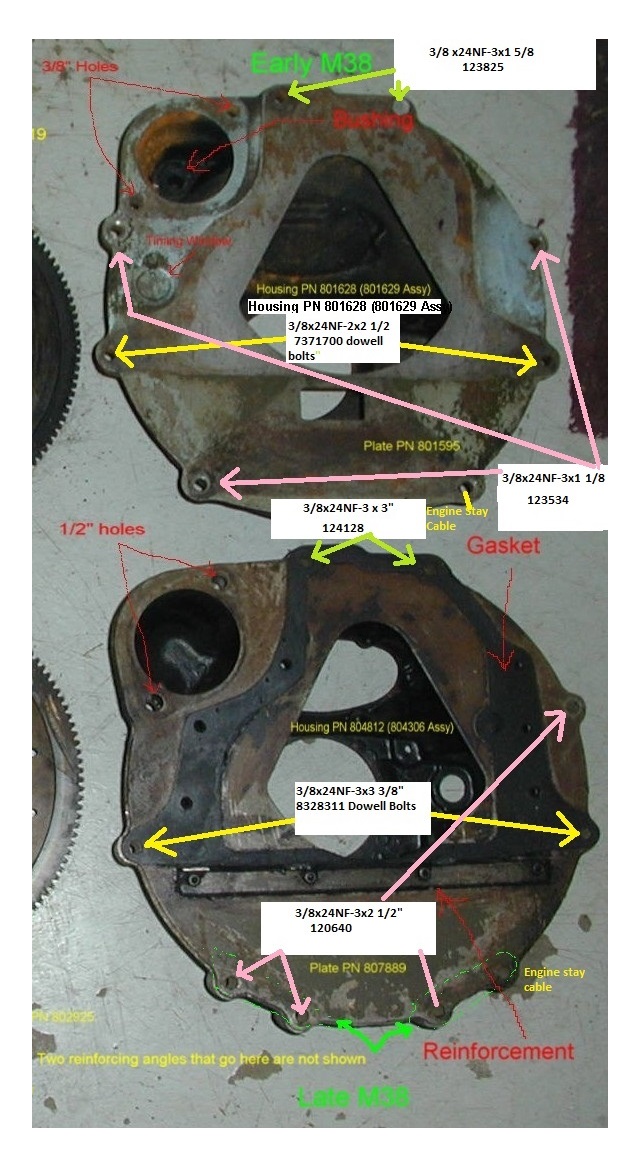

Here's a comparison of bell adapter plates early vs late:

Here's the late vs early dowell bolts:

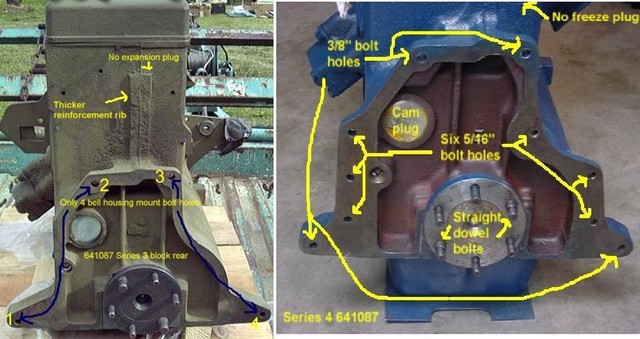

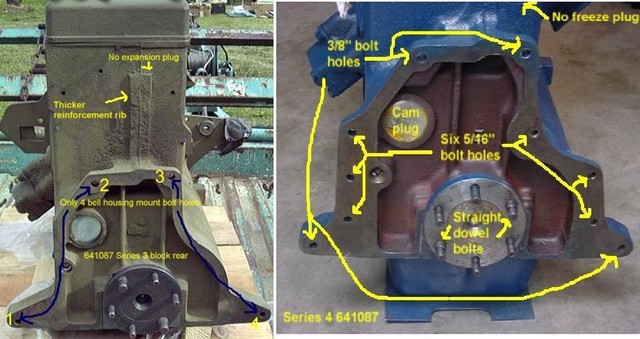

This shows the rear face of the early vs late blocks if you have the L134.

To avoid getting folks heading down the wrong track you should always include the model of your jeep in your post. Yes many things are the same but many are also no where near close. You can make it very easy by amending your signature element in your web site profile to include the first name you prefer to be addressed with and the make/model/year of your jeep.

My reply to your post below is based on the possibility your jeep could be one of 3 models this web site applies to.

Your flywheel is suppose to have two locating dowells. Early were tapered and later are straight. It allows the flywheel to be installed two positions each 180 degrees off as opposed to the other. Makes no difference with later engines that do not use the flywheel markings for ignition timing however if you are working on an early engine with the small hole in the bell housing adapter plate for access to the flywheel timing marks then it does make a difference.

On another note if your engine has been balanced in the field it may become an issue on the flywheel positioning if the flywheel was used for the balance weight adjustments or if the flywheel is significantly out of balance.

Here's the early setup with the timing mark inspection window on the pass. side of the bell housing adapter plate:

Here's a comparison of bell adapter plates early vs late:

Here's the late vs early dowell bolts:

This shows the rear face of the early vs late blocks if you have the L134.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php