M38 fording system vacuum leak?

- 4x4M38

- Jeep Legend

- Posts: 3487

- Joined: Thu May 29, 2014 6:00 pm

- Location: Texas Hill Country

-

RonD2

- Jeep Legend

- Posts: 2070

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

Hi JeepDaddy,

I'm going to ask this question --- only because I came across your post two years ago this month asking if the PCV on your M38A1 was installed backwards --- http://willysmjeeps.com/v2/modules.php? ... hlight=pcv

Have you double-checked your M38 for the same?

And it's line all the way down to the valve cover is also clean and open?

I'm going to ask this question --- only because I came across your post two years ago this month asking if the PCV on your M38A1 was installed backwards --- http://willysmjeeps.com/v2/modules.php? ... hlight=pcv

Have you double-checked your M38 for the same?

And it's line all the way down to the valve cover is also clean and open?

Ron D.

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

-

JeepdaddyRC

- Active Member

- Posts: 184

- Joined: Thu Jan 09, 2020 6:00 pm

-

RonD2

- Jeep Legend

- Posts: 2070

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

Hi JeepDaddy,JeepdaddyRC wrote:I wish I had a spare carb.

Reluctant to ask... anyone have a spare I could use for a short time?

It could solve this mystery.

With patience and saving up by eating plenty baloney sandwiches for a while, last month I found and bought a good YS-637S core for a spare. Sent it off to ScoutPilot for rebuild, got it back a couple of weeks ago.

I have right at $550 in it (about $75 of that is shipping cost back and forth).

Before exploring a possible loan, I have a few other thoughts.

ScoutPilot is well known for superior work, and you saw your carb operate correctly on his motor. While it's possible there's a defect in it, I seriously doubt it. Odds are slim.

Before buying or borrowing a spare I think it'd be more economical to send it back to him for a check.

But I'd bet he doesn't find anything wrong.

With all your fuel line cleaning you still haven't been able to test your pump volume (which still needs to be eliminated as a possibility).

Because I don't know the history of your pump and how it's installed, I ask these questions (and assuming it's a correct part numbered pump for a M38):

It's mounted with the correct 5/8-inch spacer to the block?

When it was installed, was the diaphram preloaded as described in the manual?

You cannot smell gasoline on the dipstick?

With all your checking and searching for leaks, I think the odds are also slim that you have either a vacuum or fuel line leak problem.

Your fuel tank has a clear vent line to the air filter and a vented gas cap (valve open)?

Until you can get a good volume test on the pump, I'm wondering if you were to disconnect the fuel line from the pump to the carb (take the pump temporarily out of the equation), and manually fill the float bowl --- that should be enough fuel to start and run the motor for a few minutes to see if the situation improves.

Alternately, I think you could rig a small gas can to gravity feed gas into the carb for the same test.

You don't necessarily need to swap another YS-637S to eliminate your carb as the problem.

I believe you could just as easily use a much less rare and less expensive CJ carb (Carter WO) to do the same thing.

And just a thought: ScoutPilot may have one in stock ready-to-go.

And maybe he'd be willing to rent one to you?

I keep thinking you told us the jeep ran fine until you put this carb on it, so maybe this long post is just spinning wheels.

Good luck!

Ron D.

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

-

JeepdaddyRC

- Active Member

- Posts: 184

- Joined: Thu Jan 09, 2020 6:00 pm

-

RonD2

- Jeep Legend

- Posts: 2070

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

- oilleaker1

- Jeep Enthusiast

- Posts: 973

- Joined: Wed May 13, 2009 6:00 pm

- Location: South Dakota

Wow, this one is putting it to you. Drilling out the base gasket rivets? I've never heard of that. Using a bolt and washers to squish them flat, yes. They definitely can cause a vacuum leak. I've put one thin paper gasket, top and bottom to help seal around those copper base gasket rivets. The dirt/ rust is another deal breaker, but you cleaned it all out. You checked fuel pressure. The stumble off idle is a trait that has caused me much grief with the vacuum operated carburators. I have 3 M38's that run them. One I gave up on and installed a WO civilian carb. At high altitude, they are the worst choice to use since you lose one inch of vacuum per 1000 feet. The long dip tube that drops into the well for idle circuit has two very tiny side holes or orifices that are very easily plugged. That can starve your idle fuel supply. I've had a small brass spec lodged in one that caused me $&%. I trouble shot this by spraying carb clean into the carburator inlet to make it run at a idle. This proved it was a no idle mixture fuel supply issue. You might give that a try. I'm suspicious of the rivet drilling also. Anyway, a couple of thoughts I had. Also, are you venting the distributor body with a orificed "T" ? If not orificed, you have a vacuum leak. I did see you had the vacuum port plugged into the gage, so that would/should eliminate the orificed "T". Another thing is on '51 M38's with the cold weather primer, that too can cause a vacuum leak, but I don't see it on your manifold. Hang in there, Oilly

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

Oilly,

Glad you mentioned the rivet drilling issue. Here's all 3 views of the diffuser/base gasket. This gasket should be used with two thin plain gaskets, one top and one bottom. I don't see anything needing drilling.

Glad you mentioned the rivet drilling issue. Here's all 3 views of the diffuser/base gasket. This gasket should be used with two thin plain gaskets, one top and one bottom. I don't see anything needing drilling.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

-

JeepdaddyRC

- Active Member

- Posts: 184

- Joined: Thu Jan 09, 2020 6:00 pm

Thanks for hanging in there with me.

I've tried 2 different carb base gaskets.

1. The one in the MWM rebuild kit (several layers of asbestos type material, pretty thick) without the diffuser

2. The gasket pictured below. I try to avoid Omix products, but only one available. I've used these on a GPW with success. The drilling was to remove the copper "rivets" which some claim don't compress and can cause a leak. Only removed the rivets and it did not compromise the integrity of the gasket.

Carb spray at base gasket was always one of my first tests. No change in rpms with either gasket. Ordered another from MWM.

Do you recommend the diffuser style on the M38 with YS637S?

I've tried 2 different carb base gaskets.

1. The one in the MWM rebuild kit (several layers of asbestos type material, pretty thick) without the diffuser

2. The gasket pictured below. I try to avoid Omix products, but only one available. I've used these on a GPW with success. The drilling was to remove the copper "rivets" which some claim don't compress and can cause a leak. Only removed the rivets and it did not compromise the integrity of the gasket.

Carb spray at base gasket was always one of my first tests. No change in rpms with either gasket. Ordered another from MWM.

Do you recommend the diffuser style on the M38 with YS637S?

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

The diffuser (Insulator) is required on the M38. Today vendors supply what they have regardless of part number accuracy. Since these parts are becoming very rare this issue is greater now then it ever was. It improves fuel/air mixing or atomization especially while the engine is cold or at low RPM's. It is listed by number in the M38 parts manual. Those two copper things are actually sleeves not rivets and were not an original part of the diffuse/insulator base gasket for the M38. The engine manual for the M38 lists the base gasket clearly as the Diffuser TM 9-1804A pg 96. You can use the plain thick insulator base gasket but the engine will behave poorly at low RPMs and when cold.

The gasket you drilled the sleeves out of was the WWII MB A6357 (Carter 1A55) gasket.

If you google the WWII part number you can find them without the copper sleeves:

The gasket you drilled the sleeves out of was the WWII MB A6357 (Carter 1A55) gasket.

If you google the WWII part number you can find them without the copper sleeves:

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

-

JeepdaddyRC

- Active Member

- Posts: 184

- Joined: Thu Jan 09, 2020 6:00 pm

Wes, NOS gasket above ordered. Thank you.

RonD2 and others, I read where you torqued manifolds together at heat riser area, then had the block faces milled flat by a machine shop. Is this still considered a wise move?

They are very close to flat now when bolts are loose (on the kitchen countertop) but not perfect.

RonD2 and others, I read where you torqued manifolds together at heat riser area, then had the block faces milled flat by a machine shop. Is this still considered a wise move?

They are very close to flat now when bolts are loose (on the kitchen countertop) but not perfect.

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

If you assemble them to the engine, run it up, and find no leaks you are fine. If they do leak then it would be wise to have them machined as an assembled set. There is not a published by the manufacture allowance for manifold variance. We all know that a wee bit of variance can be tolerated.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

- Xamon

- Jeep Enthusiast

- Posts: 593

- Joined: Mon Sep 17, 2012 6:00 pm

- Location: South East Saskatchewan

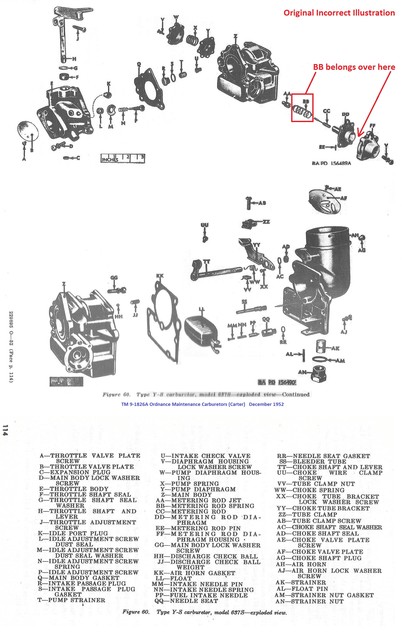

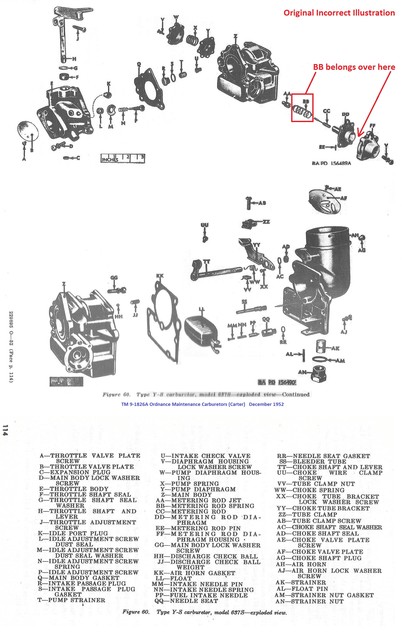

Just going to ask , would that spring in the carb that the manual shows in the wrong place cause this type of issue?

Carievale Saskatchewan Canada

http://www.willysmjeeps.com/v2/modules. ... _album.php

http://www.willysmjeeps.com/v2/modules. ... _album.php

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

Good point. Jeep Daddy can you confirm this spring location in your carb????

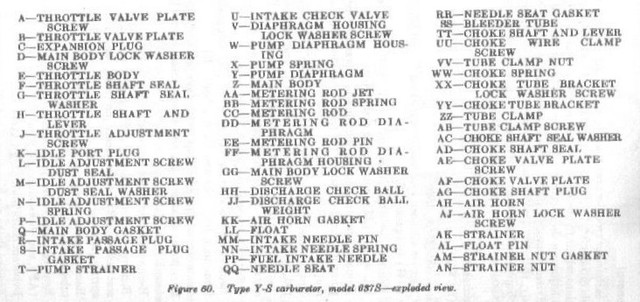

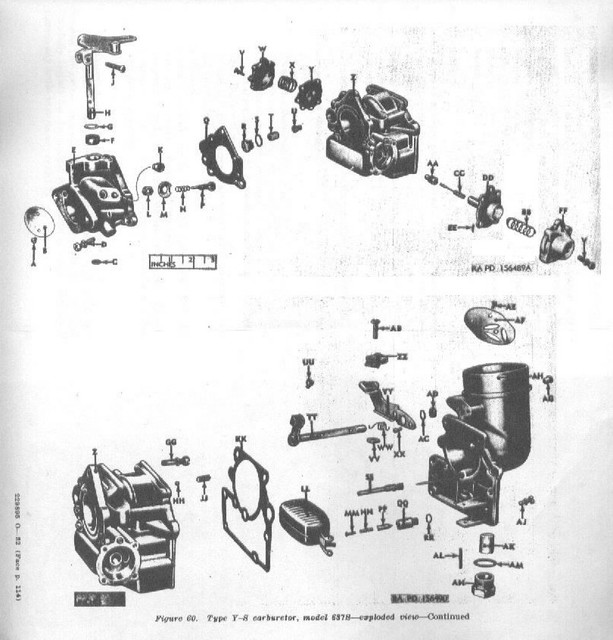

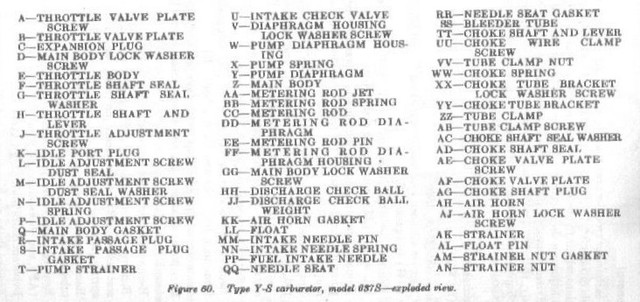

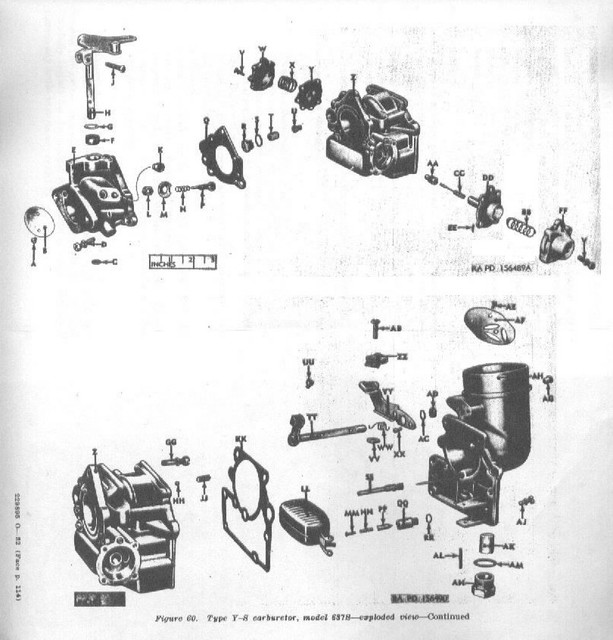

Original TM 9-1826A drawing 114

Index for Fig 114

My corrected drawing for 114

Original TM 9-1826A drawing 114

Index for Fig 114

My corrected drawing for 114

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

-

RonD2

- Jeep Legend

- Posts: 2070

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

I suppose anything is possible, but JeepDaddy's carb was rebuilt by Scout Pilot and test run on his motor.

What are the odds that Scout Pilot put the spring in the wrong place?

Scout Pilot rebuilds many YS-637S carbs.

What are the odds they're all rebuilt wrong?

Slim to none if you ask me.

On machining manifold mating surfaces together --- I had mine done incidental to other machine work done on my block for a rebuild.

It didn't leak beforehand, but there was some pitting from past leaks.

The machine work was inexpensive and worth the peace of mind.

Have you done anything to eliminate the fuel pump as the problem?

What are the odds that Scout Pilot put the spring in the wrong place?

Scout Pilot rebuilds many YS-637S carbs.

What are the odds they're all rebuilt wrong?

Slim to none if you ask me.

On machining manifold mating surfaces together --- I had mine done incidental to other machine work done on my block for a rebuild.

It didn't leak beforehand, but there was some pitting from past leaks.

The machine work was inexpensive and worth the peace of mind.

Have you done anything to eliminate the fuel pump as the problem?

Ron D.

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari