I am happy to announce that we have finally been able to work on the issues that were mentioned on this forum.

Here are the answers to the issues posted :

1. The height of the panel is at least 1/8 inch short. I measured from the front edge of the step upward using a square, the height to the top of the panel was 14.5 inches. The original panel was between 14 5/8 and 14 11/16. I measured both left and right MD Juan cowls and the measurement was the same, 14.5.

Action:

It is now corrected, the height of the panel now 14 5/8” (same as the original.)

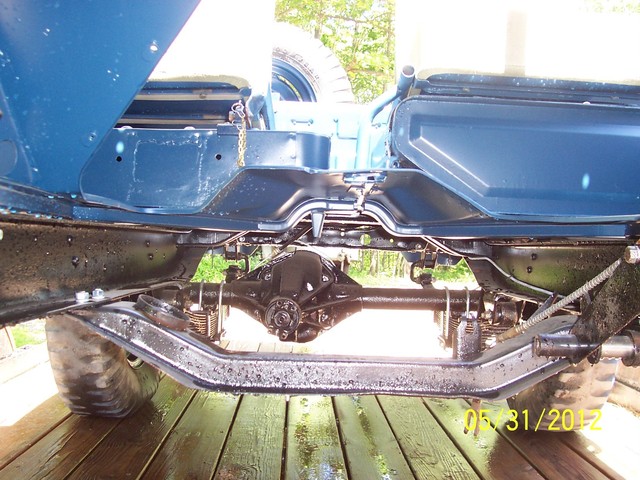

2. The step is made wrong. I had purchased a NOS front floor/firewall panel. After installing it in the body I attempted to fit the MD Juan left lower cowl. It would not match up due to the hat channel on the floor that runs underneath the step. The hat channel was either too long or the step on the MD Juan panel was mis-shapened. I compared measurements and angles for that part of the hat channel with the remainder of the hat channel on my removed floor and found the original was a match in all respects for the NOS one I had purchased.

The same problem existed for the right cowl but I didn’t spend as much time on it as the left.

The step is actually made correctly but we just put a little allowance on the hat channels so that the user has some leeway and be able to do adjustments.

3. The gusset for the upper corner where the fender bolts is attached making it hard to properly to fit the panel with the firewall.

There is a gusset in the top corner of the lower cowl. This gusset has a hole cut in it for the wiper vacuum line and has a cage nut on it for the upper fender nut. This gusset is included and welded to the MD Juan panel. However it causes a problem because that gusset, at least on my original parts, not only is attached to the cowl but overlaps the lip of the firewall to get the panel and firewall to fit and position correctly. It appears to me that this gusset was added to the body at the factory after or at the same time the firewall and cowl are mated up.

We really do a little hammering on the lip portion of the gusset that connects with the firewall.

4. The original panels, in fact the whole top portion of the jeep body had a lip that is bent down into a U shape and then another piece of U shaped channel is pushed or secured into the channel that finishes off the top of the panels. The MD Juan does not have the second U channel but it does appear to be made from a heavier gauge metal.

We install a “U” shaped stiffener attached inside of the upper side panel.

5. MD Juan attaches the cowl support that fits up under the upper cowl. The support does not look the same as the original and I think it inhibits fitting the part.

We will implement the correct cowl support based from the original on our next production.

6. Lastly but very important the angle of the front edge of the cowl where it is supposed to meet the fender is wrong. If you bolt up at the top the gap at the bottom seems to be about 3/16 to ¼ inch. I compared it to poster board templates I made of the side of the jeep before I started taking it apart and to the original cowl.

We now assure the 105 degree correct stamped angle of the bend based from the standard .