Greetings,

I am in the process of trying to take off the front transfer case yoke (at front driveshaft) to get at the seal due to leakage. can anyone please explain in detail and in point form how this is accomplished....it looks easy and I am only a weekend warrior garage mechanic and have never done this before. Do I require a yoke puller and if so which one? How do I keep the whole yoke from turning as I try to take off the yoke bolt and how do I retighten the yoke bolt and to what torque?

Thanks in advance,

lesk

Transfer Case Yoke Seal-to front driveshaft.

Moderators: TomM, Moderator, wesk

No need to ask another member to recite the procedure in such great detail. The entire procedure is clearly laid out in the M38 TM 9-1804B, Drive Train maintenance starting on page 71, Chapter 6, Transfer.

If you do not have this manual you can download it in PDF here on our downloads page for free! http://www.willysmjeeps.com/v2/modules. ... oad&cid=62

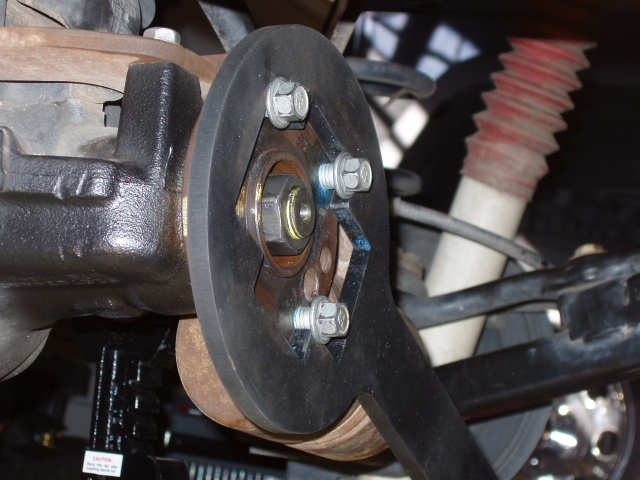

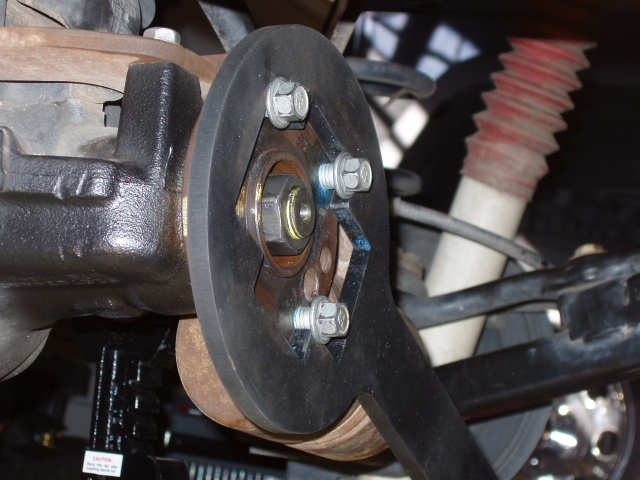

The special holding tool for the transfer case Yokes and the drive axle pinion yokes can be fabricated by yourself or purchased from automotive tool dealers.

My photo album is full of hundreds of detailed technical photos that will usually answer most of your questions on any M38/M38A1/M170 topic.

These four tools were fabricated by the individual doing the work.

This is a Kent-Moore Tool Company version for sale commercially. They are not cheap. J-8410-01

The yoke is retained by a nut, 3/4-16NF, and the correct torque is not listed anywhere in the military manuals. This is where the civvy CJ manuals come in handy. The civvy manual of choice to use with the M38 is the early CJ manual:

But this version does not have a general torque chart by bolt size and thread pitch.

The later CJ manual normally used with the M38A1 :

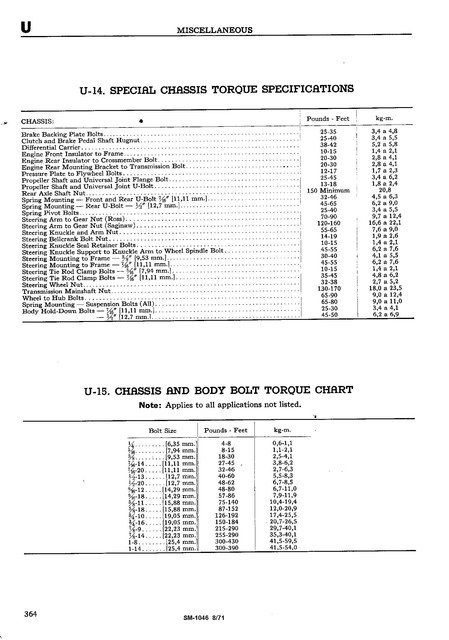

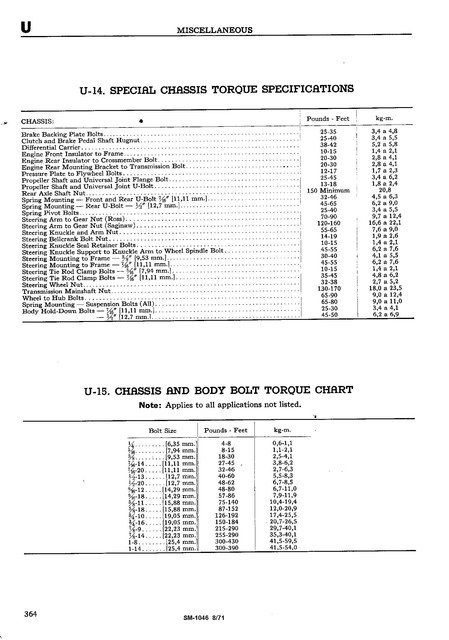

This one does have a general torque Chart.

If you use the lower chart and have looked up the nut size in the parts manual you can select the correct torque to use. I have already confirmed the nut size from the parts manual as 3/4-16NF, thus your needed torque is 150-184 Foot Pounds. Since it uses a cotter pin you only tighten it to 150 and check for alignment of the cotter p[in holes with the nut slots. slowly increase the torque until the holes line up. Try not to exceed 184 foot pounds.

If you do not have this manual you can download it in PDF here on our downloads page for free! http://www.willysmjeeps.com/v2/modules. ... oad&cid=62

The special holding tool for the transfer case Yokes and the drive axle pinion yokes can be fabricated by yourself or purchased from automotive tool dealers.

My photo album is full of hundreds of detailed technical photos that will usually answer most of your questions on any M38/M38A1/M170 topic.

These four tools were fabricated by the individual doing the work.

This is a Kent-Moore Tool Company version for sale commercially. They are not cheap. J-8410-01

The yoke is retained by a nut, 3/4-16NF, and the correct torque is not listed anywhere in the military manuals. This is where the civvy CJ manuals come in handy. The civvy manual of choice to use with the M38 is the early CJ manual:

But this version does not have a general torque chart by bolt size and thread pitch.

The later CJ manual normally used with the M38A1 :

This one does have a general torque Chart.

If you use the lower chart and have looked up the nut size in the parts manual you can select the correct torque to use. I have already confirmed the nut size from the parts manual as 3/4-16NF, thus your needed torque is 150-184 Foot Pounds. Since it uses a cotter pin you only tighten it to 150 and check for alignment of the cotter p[in holes with the nut slots. slowly increase the torque until the holes line up. Try not to exceed 184 foot pounds.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

Yoke Tools & Manual

Wow....thanks Wes....tools, a manual and torque specs....that's all I require...one last question though....do both front and rear yokes on the front driveshaft use the same yoke and seal?

Very best regards,

lesk

Very best regards,

lesk

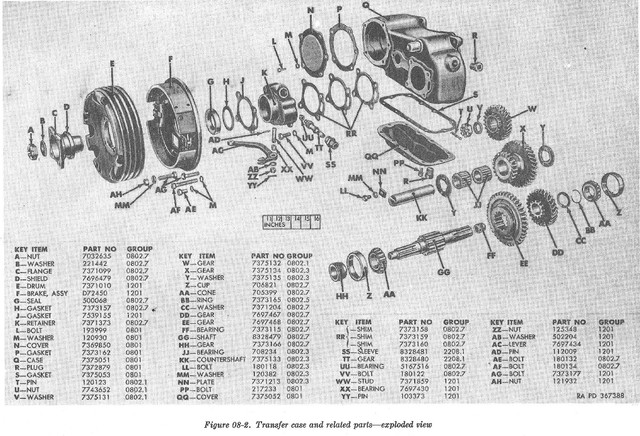

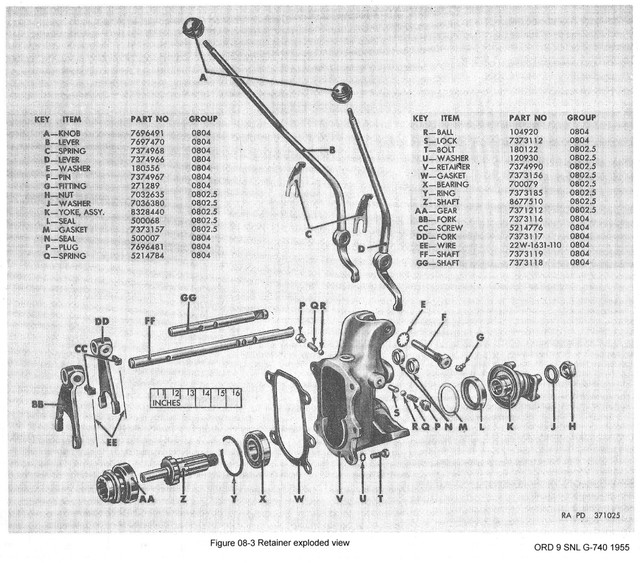

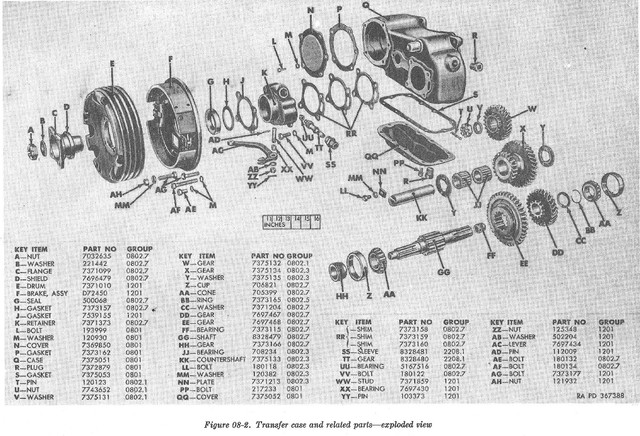

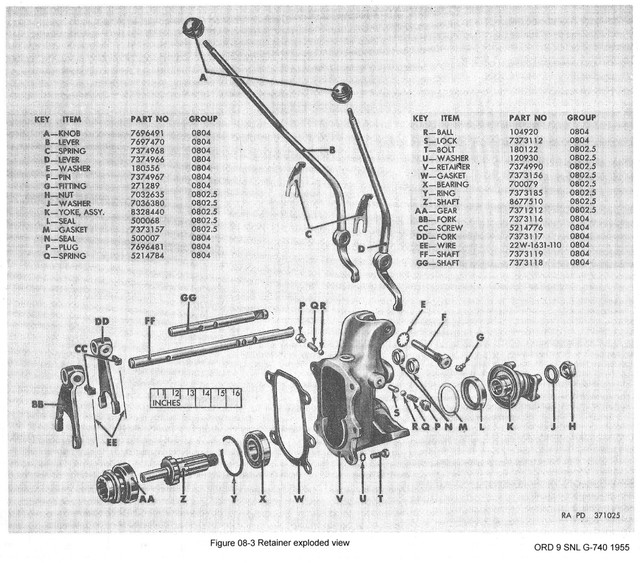

As always the answer to that question is in the parts manual. Both Canadian & US. The US ORD 9 pages 196 & 197. If you do not have either then the US ORD 9 is on the same downloads page and it is free as well.

Rear items C, D, G & H

Front items K, L & M

The 2 illustrations above were lying in my photo album I referred to in my first reply.

Rear items C, D, G & H

Front items K, L & M

The 2 illustrations above were lying in my photo album I referred to in my first reply.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

The forged unit is about 1/4" thick and the stamped or rolled steel units appear to be 3/16" to 1/4" thick.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php