Hi fellows,

I went through the TM 9-8015-1 "Enginge & Clutch".

Installation of the pulley is mentioned on page 124 - but does not mention the torque for the nut.

Please help...

2nd question: is there a chart available which mentions the torques used on the M38A1 in a list?

Thank you

&

regards

Philipp

M38A1 - correct torque install fan/generator drive pulley

-

pduske

- Member

- Posts: 30

- Joined: Tue Jan 31, 2006 6:00 pm

M38A1 - correct torque install fan/generator drive pulley

´57 M38A1

Ramsey 50R setup

USMC spec. PowrLok front & rear

Meyer ST 84 plow

Ramsey 50R setup

USMC spec. PowrLok front & rear

Meyer ST 84 plow

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

The norm is to use a Standard Torques Chart anytime a specific torque is not listed for an application. To determine the torque for a fastener in the general torque charts you must first ID the fastener. (Diameter, thread pitch, SAE Grade, and material. You can find this info usually in the applicable parts manual.

Unfortunately the Army failed to include one in the vehicle specific manuals.

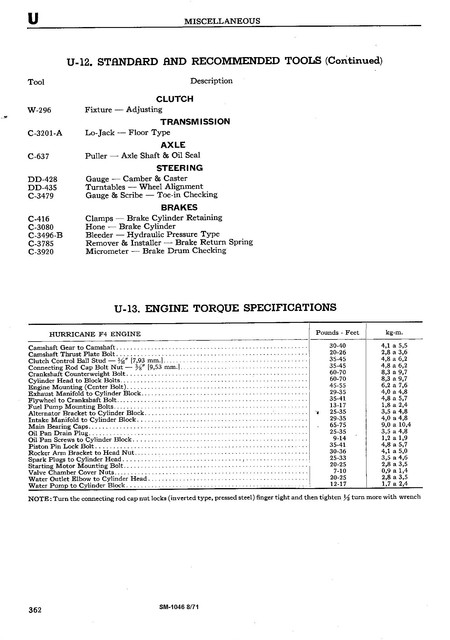

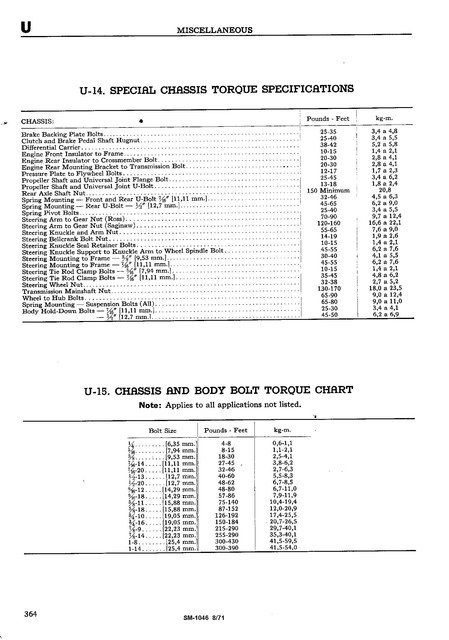

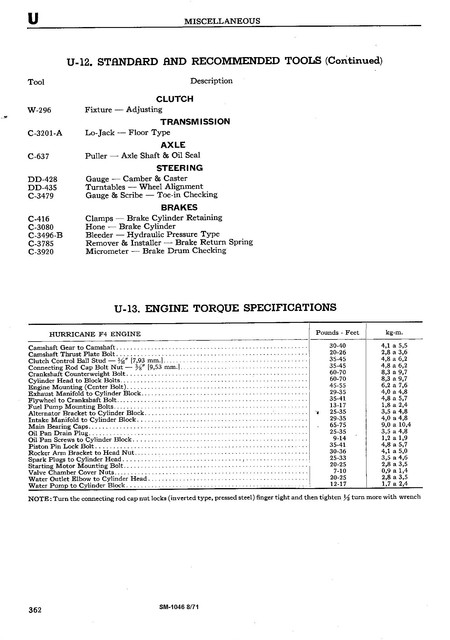

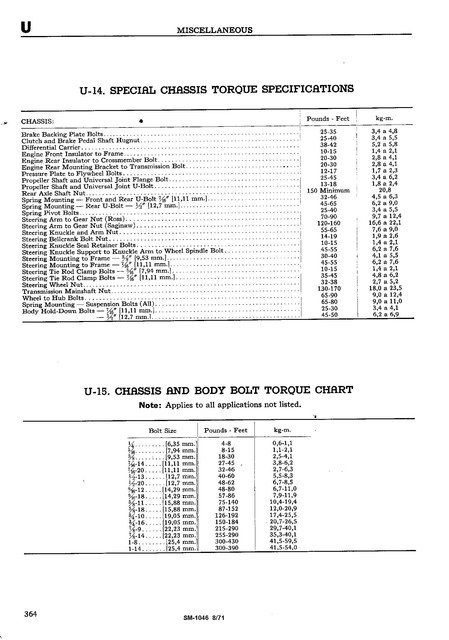

There are many on the internet that you can download. Just ask for an "Automotive Standard Torque Chart. The Willys/Kaiser civilian manuals do have short listings for specific parts in their appendix but no general charts. The CJ5 Service Manual SM 1046 is you best bet for civvy manual help. The Application Specific Torque charts and the general torque charts I have posted in my photo albums.

Civvy SM-1046 Manual:

http://www.willysmjeeps.com/v2/modules. ... _album.php

This bottom chart is not a very good general torque chart because it does not specify bolt thread pitch nor SAE rating.

General Torgue Spec Charts:

http://www.willysmjeeps.com/v2/modules. ... _album.php

This is a much more useful General Torques Chart.

Unfortunately the Army failed to include one in the vehicle specific manuals.

There are many on the internet that you can download. Just ask for an "Automotive Standard Torque Chart. The Willys/Kaiser civilian manuals do have short listings for specific parts in their appendix but no general charts. The CJ5 Service Manual SM 1046 is you best bet for civvy manual help. The Application Specific Torque charts and the general torque charts I have posted in my photo albums.

Civvy SM-1046 Manual:

http://www.willysmjeeps.com/v2/modules. ... _album.php

This bottom chart is not a very good general torque chart because it does not specify bolt thread pitch nor SAE rating.

General Torgue Spec Charts:

http://www.willysmjeeps.com/v2/modules. ... _album.php

This is a much more useful General Torques Chart.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

-

jnissen

- Contributor

- Posts: 93

- Joined: Fri May 11, 2018 6:00 pm

- Location: Austin Texas

- Contact:

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

That is pretty thoughtful but would not be the determing factor since the bolts secure the fan to the pulley and pulley to the pump flange rotational torque is being applied directly to the 4 bolts by the fan when it is turning while the belt is driving it.

Rather then guess at a torque the simple plan is to just ID the 4 bolts and select the correct torque from the general torque chart.

The Bolts are 1/4-20 Zinc plated and usually grade 5 so the standard torque would be 10 Ft Lbs.

Rather then guess at a torque the simple plan is to just ID the 4 bolts and select the correct torque from the general torque chart.

The Bolts are 1/4-20 Zinc plated and usually grade 5 so the standard torque would be 10 Ft Lbs.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

-

jnissen

- Contributor

- Posts: 93

- Joined: Fri May 11, 2018 6:00 pm

- Location: Austin Texas

- Contact:

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

Looking at the title again it appears we both were off the spot a bit. Not the water pump pulley and not the generator pulley. Instead I think he is looking for the torque for the crankshaft pulley nut which is a 1 1/16" -16 NF nut and all my charts only address 1 1/8" or 1" which puts the torque range in a shear application at 180 to 300 Ft Lbs.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php