M38 Bell Crank Bolt Tourqe

- 1stSgtUSMC

- Member

- Posts: 44

- Joined: Sat Jun 22, 2019 6:00 pm

- Location: Maine then South Carolina

M38 Bell Crank Bolt Tourqe

I am re building my steering and am asse3mbling my rebuilt bell crank and am not sure how tight the bell crank bolt should be...I am assuming there is a tourqe. Can anyone assist? Thank you!

S/F

Kevin

S/F

Kevin

Semper Fi

1stSgt USMC Active Duty

1952 M38

1966 614M Trailer

1stSgt USMC Active Duty

1952 M38

1966 614M Trailer

-

RonD2

- Jeep Legend

- Posts: 2070

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

Hi Kevin,

Are you asking about the large vertical bolt and nut that goes through the bell-crank and its bearings and seals, or are you asking about the smaller horizontal bolt and nut that clamps the fixed cast housing around the vertical bolt and bellcrank?

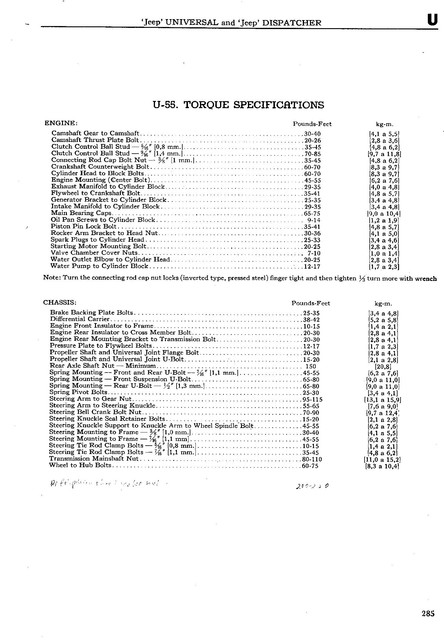

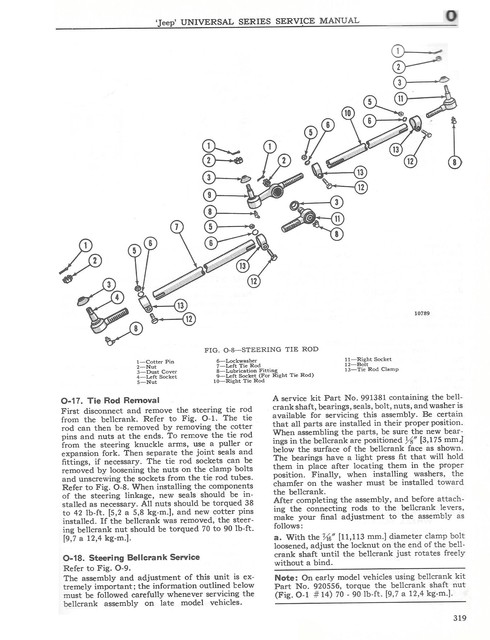

According to my copy of the Willys Universal Service Manual (page 275), the torque for the clamping bolt is 70-90 ft.lbs.

I'm not aware of a torque spec for the vertical bolt (the manual says "tighten") because I believe it's machined so as to prevent any over-tightening that would interfere with or damage the upper and lower bearing seals. Once it's tight it's tight. My copy of the ORD9 SNL calls for a self-locking nut. You have one of those?

Question is: which one gets the wrench first?

Steering is nothing to mess around with.

Are you asking about the large vertical bolt and nut that goes through the bell-crank and its bearings and seals, or are you asking about the smaller horizontal bolt and nut that clamps the fixed cast housing around the vertical bolt and bellcrank?

According to my copy of the Willys Universal Service Manual (page 275), the torque for the clamping bolt is 70-90 ft.lbs.

I'm not aware of a torque spec for the vertical bolt (the manual says "tighten") because I believe it's machined so as to prevent any over-tightening that would interfere with or damage the upper and lower bearing seals. Once it's tight it's tight. My copy of the ORD9 SNL calls for a self-locking nut. You have one of those?

Question is: which one gets the wrench first?

Steering is nothing to mess around with.

Ron D.

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

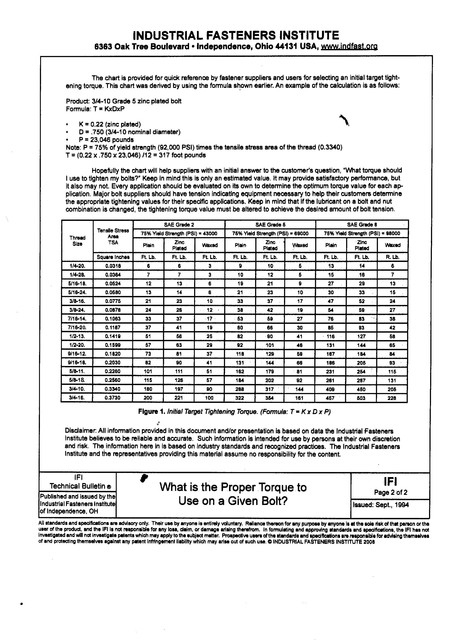

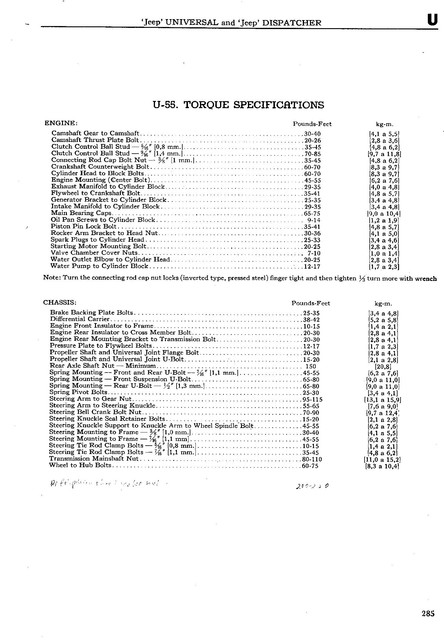

Not quite right Ron. Good try though. It is good to keep a copy of SM-1002 civvy CJ Factory Service Manual on the bench. When the TM 9-8012 & TM 9-1804B come up short on installation info it becomes a handy source of additional data. Especially the special torque charts in the appendix of the SM-1002 that is conspicuously missing in the TM's. To use these charts which are often clearly labeled to reduce errors one must have a good working sense of standard torque values placed on all hardware based on size, thread pitch and rating/grade. In this business anytime a special torque is not provided in the service manual then the standard general torque for that bolt/nut diameter, thread pitch and grade is to be used.

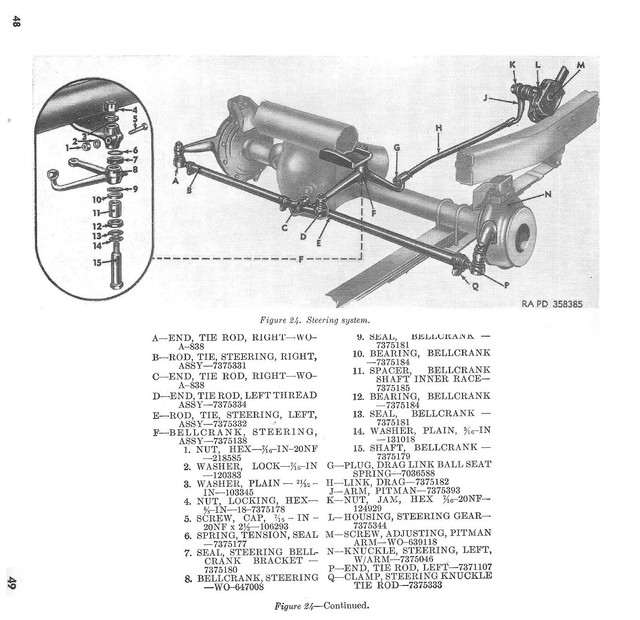

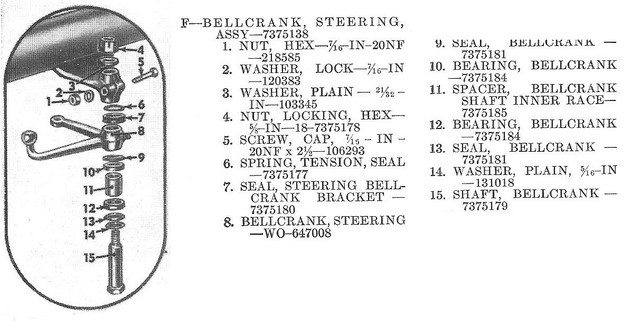

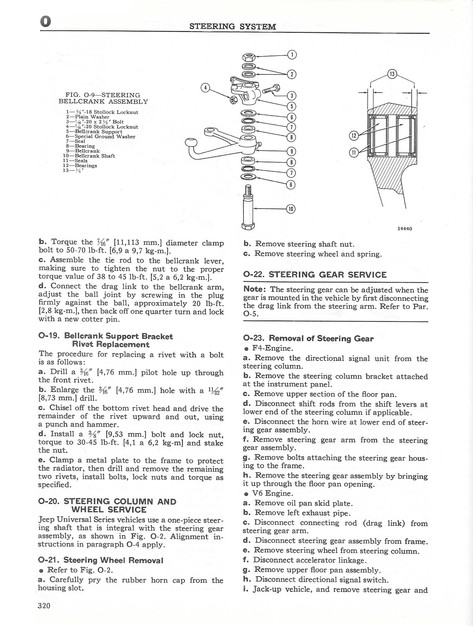

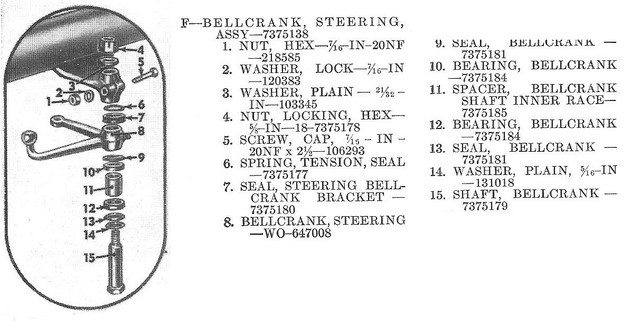

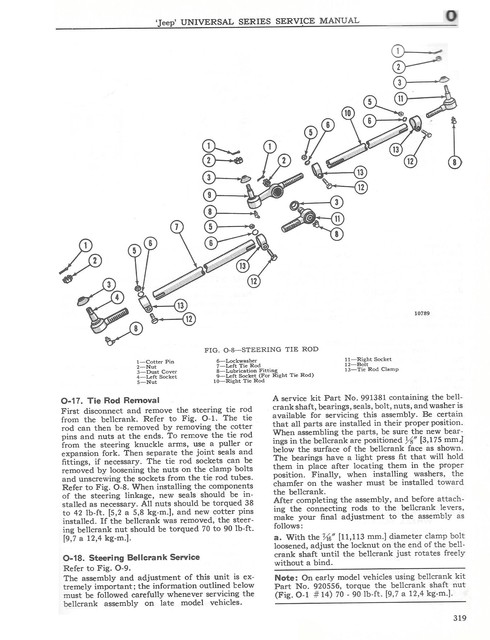

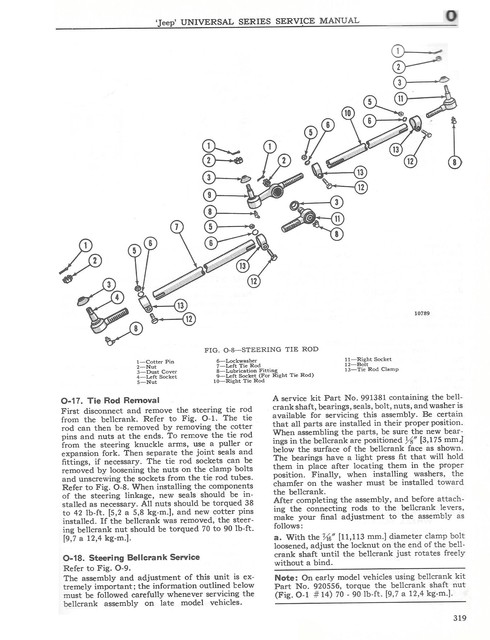

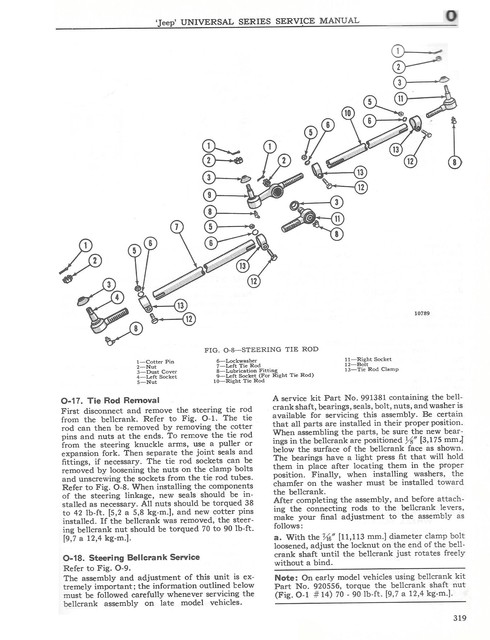

Here is the illustration for the bellcrank in question found in our primary reference TM 9-1804B.

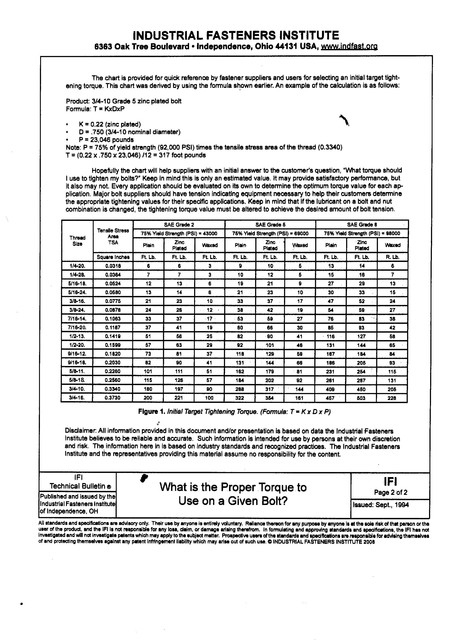

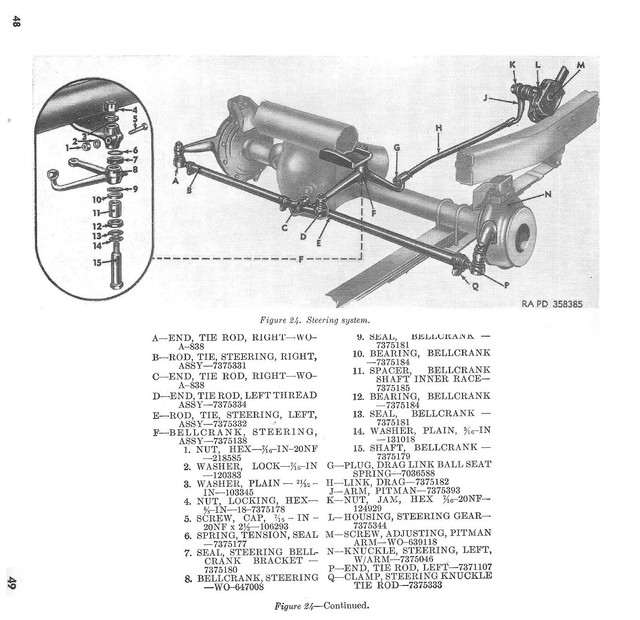

The two bolt/nut combination's torque we are determining are the pinch bolt #1 & #5 and the vertical shaft / nut #15 & #4. Since the Army didn't offer us a special torque value for either set we must determine the basic torque value from a grad 5 or grade 8 standard torque chart. Just happens I have a set of these in my photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

Here's the page to use:

Our parts manual helps with fastener ID.

ORD# 124139 Bolt, Mac, S, Cad/zn pltd, 7/16-20NF-3x2 1/4

ORD# 218585 Nut, hex, S, Cad/zn pltd, 7/16-20NF-2

Assume at least grade 5 std torque is 60-66 Ft Lbs

ORD# 7375179 Shaft, bellcrank

ORD# 7375178 Nut, locking, bellcrank pivot shaft 5/8-18NF

Assume at least grade 5 std torque 184-202 Ft Lbs

Larger file link: http://willysmjeeps.com/v2/modules/gall ... orques.jpg

Items 1, 4, 5 & 15 are the items we are focusing on.

Since we are in the M38 military manual where no special torques are listed we should proceed with the std torques on these two nuts.

If we compare our situation with the civvy CJ manual sm-1002 special torques chart:

16th item under chassis. 70-90 Ft Lbs is close to our standard torque for the pinch bolt although a wee bit high.

Biggest problem is a lack of accurate detailed assembly instructions for the bellcrank in all three of these referenced manuals. But if you visit Civvy CJ manual SM-1046 you'll find a much more detailed set of assembly instructions. This manual is geared more towards the CJ-3B and CJ5.

Here is the illustration for the bellcrank in question found in our primary reference TM 9-1804B.

The two bolt/nut combination's torque we are determining are the pinch bolt #1 & #5 and the vertical shaft / nut #15 & #4. Since the Army didn't offer us a special torque value for either set we must determine the basic torque value from a grad 5 or grade 8 standard torque chart. Just happens I have a set of these in my photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

Here's the page to use:

Our parts manual helps with fastener ID.

ORD# 124139 Bolt, Mac, S, Cad/zn pltd, 7/16-20NF-3x2 1/4

ORD# 218585 Nut, hex, S, Cad/zn pltd, 7/16-20NF-2

Assume at least grade 5 std torque is 60-66 Ft Lbs

ORD# 7375179 Shaft, bellcrank

ORD# 7375178 Nut, locking, bellcrank pivot shaft 5/8-18NF

Assume at least grade 5 std torque 184-202 Ft Lbs

Larger file link: http://willysmjeeps.com/v2/modules/gall ... orques.jpg

Items 1, 4, 5 & 15 are the items we are focusing on.

Since we are in the M38 military manual where no special torques are listed we should proceed with the std torques on these two nuts.

If we compare our situation with the civvy CJ manual sm-1002 special torques chart:

16th item under chassis. 70-90 Ft Lbs is close to our standard torque for the pinch bolt although a wee bit high.

Biggest problem is a lack of accurate detailed assembly instructions for the bellcrank in all three of these referenced manuals. But if you visit Civvy CJ manual SM-1046 you'll find a much more detailed set of assembly instructions. This manual is geared more towards the CJ-3B and CJ5.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

-

RonD2

- Jeep Legend

- Posts: 2070

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

Wes,

184 to 202 foot pounds for the 5/8-18 bell crank shaft and nylon lock nut? I'm a rookie, but that seems awfully heavy. I don't think I'm going to try that at home.

Like most things in America, there's many torque tables out there, and I know it takes careful study, including the application, consideration of the grade of the fasteners, and whether they're plated, un-plated, dry, lubricated, etc. The half-dozen or so torque tables I looked at seem to point at a range of about 125-145 foot-pounds for a Grade 5, un-plated, and dry 5/8-18 nut and bolt.

I also read some info on nylon lock nuts and their application with torque, including that depending on how many times they've been used they can tend to loose holding power. The recommendation was to use new nuts every time. Some question also about possibly subtracting the torque it takes to spin one on the bolt from the final torque value desired. Can't find any consistent information about nylon lock nuts and max torque values.

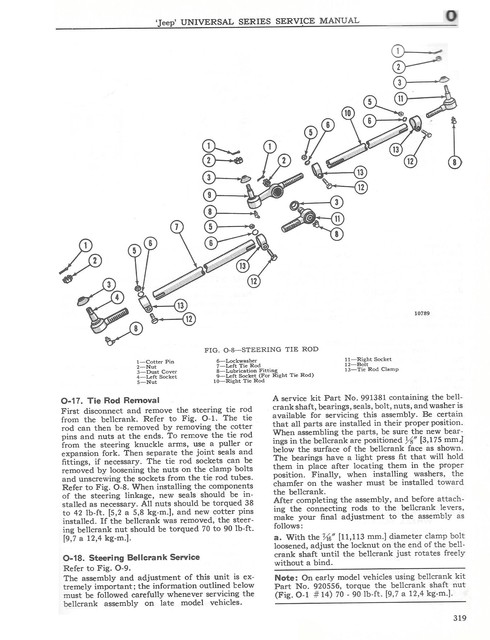

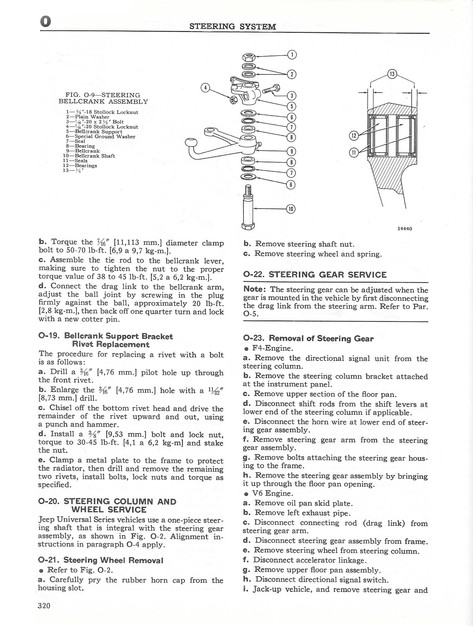

Paragraph O-18.a. above from the SM-1046 says to adjust the lock-nut on the bell crank shaft so that it just rotates freely without binding. No torque value given and none implied.

Paragraph O-18.b very clearly says to torque the cross-clamping bolt to 50-70 foot pounds. This is the only other reference to a torque value that I can find other than the torque table in the back of SM, which says 70-90 ft.lbs., an obvious unresolved conflict of values.

I torqued my clamp bolt to 80, now I'm going to back it off to 60.

Interesting topic! Thanks!

184 to 202 foot pounds for the 5/8-18 bell crank shaft and nylon lock nut? I'm a rookie, but that seems awfully heavy. I don't think I'm going to try that at home.

Like most things in America, there's many torque tables out there, and I know it takes careful study, including the application, consideration of the grade of the fasteners, and whether they're plated, un-plated, dry, lubricated, etc. The half-dozen or so torque tables I looked at seem to point at a range of about 125-145 foot-pounds for a Grade 5, un-plated, and dry 5/8-18 nut and bolt.

I also read some info on nylon lock nuts and their application with torque, including that depending on how many times they've been used they can tend to loose holding power. The recommendation was to use new nuts every time. Some question also about possibly subtracting the torque it takes to spin one on the bolt from the final torque value desired. Can't find any consistent information about nylon lock nuts and max torque values.

Paragraph O-18.a. above from the SM-1046 says to adjust the lock-nut on the bell crank shaft so that it just rotates freely without binding. No torque value given and none implied.

Paragraph O-18.b very clearly says to torque the cross-clamping bolt to 50-70 foot pounds. This is the only other reference to a torque value that I can find other than the torque table in the back of SM, which says 70-90 ft.lbs., an obvious unresolved conflict of values.

I torqued my clamp bolt to 80, now I'm going to back it off to 60.

Interesting topic! Thanks!

Ron D.

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

Well, I suppose that's the difference between Electronic Techs and Mechanics. At any rate I have been wrenching on cars, jeeps and airplanes since about 1960. I still operate my own aircraft maintenance shop and I have a good feel for which MECHANICAL Data to trust and which not to trust.

I hope you appreciated my making the SM-1046 available to you. The page from SM 1002 you quoted early on didn't have the PZAZZ the SM-1046 page has!!!

I hope you appreciated my making the SM-1046 available to you. The page from SM 1002 you quoted early on didn't have the PZAZZ the SM-1046 page has!!!

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

-

RonD2

- Jeep Legend

- Posts: 2070

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

Hi Wes,

Not my intent to challenge your resume or vastly superior knowledge, skill, and experience. Not sure why posts frequently seem to go down that path.

I'm just trying to ask a question to get some clarity out of some muddy water in the manuals that would be useful for me and perhaps other rookies. Your knowledge and experience is invaluable in that department, but only if you're willing to share it. After all, you were a rookie once upon a time, weren't you?

Maybe if I ask the question more directly -------> Did you torque the bell-crank shaft on your jeep to 184-202 foot pounds? If not, can you tell us what torque you used?

And yes, I appreciate the SM-1046 and everything else you do for us.

Thanks again.

Not my intent to challenge your resume or vastly superior knowledge, skill, and experience. Not sure why posts frequently seem to go down that path.

I'm just trying to ask a question to get some clarity out of some muddy water in the manuals that would be useful for me and perhaps other rookies. Your knowledge and experience is invaluable in that department, but only if you're willing to share it. After all, you were a rookie once upon a time, weren't you?

Maybe if I ask the question more directly -------> Did you torque the bell-crank shaft on your jeep to 184-202 foot pounds? If not, can you tell us what torque you used?

And yes, I appreciate the SM-1046 and everything else you do for us.

Thanks again.

Ron D.

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

Actually the posts tend to transition to this point when you make this type of post. It's all in your social skill set.Not my intent to challenge your resume or vastly superior knowledge, skill, and experience. Not sure why posts frequently seem to go down that path.

Now we would not be at this level had you simply asked your direct question earlier. Answer is: I was unable to determine the grade of the shaft thus those years of experience dictate you go with the lowest torque. In the chart above that is the torque for a grade 2, 5/8-18 bolt.Maybe if I ask the question more directly -------> Did you torque the bell-crank shaft on your jeep to 184-202 foot pounds? If not, can you tell us what torque you used?

Before I torqued anything I would need to determine if per this SM-1046 page I had the early or late shaft setup.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

-

RonD2

- Jeep Legend

- Posts: 2070

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

Thanks Wes! Un-plated and dry grade 2 at 115 foot-pounds it is.

Yup, I've never been much in the social skills department. I've even been known to scratch my a$$ in public once in a while.

Yup, I've never been much in the social skills department. I've even been known to scratch my a$$ in public once in a while.

Ron D.

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

- 1stSgtUSMC

- Member

- Posts: 44

- Joined: Sat Jun 22, 2019 6:00 pm

- Location: Maine then South Carolina

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

Let me say this again, weather you torque the shaft nut to a specific torque or just adjust tightness of nut so it leaves bellcrank free to move depends on which bellcrank setup you have. As I stated above and is indicated on this page of SM-1046 determine what you first.

We have very little identification info so if you wish you can torque the nut to 115 ft lbs and if you can't move the bellcrank or it is very difficult to move then I suggest you follow the late type instructions.

We have very little identification info so if you wish you can torque the nut to 115 ft lbs and if you can't move the bellcrank or it is very difficult to move then I suggest you follow the late type instructions.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

-

RonD2

- Jeep Legend

- Posts: 2070

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

Hi Kevin,

I'm going with the late style. I agree the manuals for some reason lost to history appear to neglect this crucial part of the steering system.

Accordingly, using Wes' advice and an abundance of caution, I'm going to "sneak up" on a maximum 115 foot-pounds of torque for the bell-crank shaft and nut, starting with 50% (58 foot-pounds), then checking for free operation, then backing it off and proceeding to 75% (87 foot-pounds) again checking for free operation, then backing it off and proceeding to 90% (104 foot-pounds) and checking for free operation without binding. Only then will I proceed to 115 foot-pounds.

I'm concerned that should "binding" appear it'll be too late and damage (destruction) of the bearings, races, or seals will already be done and require replacement of these parts to make things right again. Not in my budget to waste parts this way. I hate to have to experiment, but sneaking up on it seems a logical approach in the absence of clear definitive information. It still boggles my grape that this is even a question and search for knowledge about a 70-year-old design.

I'm still thinking that the design of the shaft bolt (a fancy machined shoulder bolt in other words) and the way it fits and fastens into the housing, is such that it would be nearly impossible to tighten it so much as to cause damage to any individual part, at least not before the nut would shear off the top of the shaft. But what do I know, I'm a rookie.

I'm going with the late style. I agree the manuals for some reason lost to history appear to neglect this crucial part of the steering system.

Accordingly, using Wes' advice and an abundance of caution, I'm going to "sneak up" on a maximum 115 foot-pounds of torque for the bell-crank shaft and nut, starting with 50% (58 foot-pounds), then checking for free operation, then backing it off and proceeding to 75% (87 foot-pounds) again checking for free operation, then backing it off and proceeding to 90% (104 foot-pounds) and checking for free operation without binding. Only then will I proceed to 115 foot-pounds.

I'm concerned that should "binding" appear it'll be too late and damage (destruction) of the bearings, races, or seals will already be done and require replacement of these parts to make things right again. Not in my budget to waste parts this way. I hate to have to experiment, but sneaking up on it seems a logical approach in the absence of clear definitive information. It still boggles my grape that this is even a question and search for knowledge about a 70-year-old design.

I'm still thinking that the design of the shaft bolt (a fancy machined shoulder bolt in other words) and the way it fits and fastens into the housing, is such that it would be nearly impossible to tighten it so much as to cause damage to any individual part, at least not before the nut would shear off the top of the shaft. But what do I know, I'm a rookie.

Ron D.

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

- 1stSgtUSMC

- Member

- Posts: 44

- Joined: Sat Jun 22, 2019 6:00 pm

- Location: Maine then South Carolina

sounds like a reasonable plan. My M38 is the late style. So should there be any drage on the bell crank when it move left to right? Im not sure how free its supposed to shift. or should it be somewhat stiff? it would be easier if there was a spring scale measurment on it like the front knuckles.

S/F

Kevin

S/F

Kevin

Semper Fi

1stSgt USMC Active Duty

1952 M38

1966 614M Trailer

1stSgt USMC Active Duty

1952 M38

1966 614M Trailer

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

Only reasonable assumption is that Early or Late either will rotate freely when not connected to tie rods and installed per the manual's early or late process as described. Freely usually means no spring scale needed or without noticeable friction.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

-

RonD2

- Jeep Legend

- Posts: 2070

- Joined: Wed Oct 01, 2014 6:00 pm

- Location: South Carolina, Dorchester County

Hi Kevin,

I agree it'd be easier if the manuals specified a spring scale or another clear procedure, but they don't. And they didn't bother to specify a torque value either. So here we are. I'm pretty sure Wes said he torques his own to Grade 2, unplated, and dry specs at 115 foot pounds.

I think that even with all the experience of fellow members posted here over the years that you and I might be in experimental territory.

The manual doesn't say anything about "drag". It says "move without binding". I take that to mean a full 360-degrees of "smooth" motion. "Binding" and "smooth" being in the feel of the beholder I guess. Don't forget to shoot some good grease into it first.

As I previously said, I think if I sneak up on the torque value, and each stage is "smooth" but the next one isn't --- then the damage is already done (too much torque). Scrap the parts and start over.

I think it's kind of crapola to have do it this way, but with only "reasonable assumptions" instead of clearly stated personal experience from the veterans out there that say a torque value on that nut is necessary, what else is a rookie to do? "Tighten" it like the manual says and keep your fingers crossed going down the road?

I haven't re-done mine yet. I'll go first and let you know how it turns out. I suspect I'm going to stop at 90% (105 foot-pounds) ---- if it takes that without binding ---- and go from there. 105 is a lot.

Heck, the torque for a 1/2-20 lug-nut is only about 65 foot pounds as I recall.

I agree it'd be easier if the manuals specified a spring scale or another clear procedure, but they don't. And they didn't bother to specify a torque value either. So here we are. I'm pretty sure Wes said he torques his own to Grade 2, unplated, and dry specs at 115 foot pounds.

I think that even with all the experience of fellow members posted here over the years that you and I might be in experimental territory.

The manual doesn't say anything about "drag". It says "move without binding". I take that to mean a full 360-degrees of "smooth" motion. "Binding" and "smooth" being in the feel of the beholder I guess. Don't forget to shoot some good grease into it first.

As I previously said, I think if I sneak up on the torque value, and each stage is "smooth" but the next one isn't --- then the damage is already done (too much torque). Scrap the parts and start over.

I think it's kind of crapola to have do it this way, but with only "reasonable assumptions" instead of clearly stated personal experience from the veterans out there that say a torque value on that nut is necessary, what else is a rookie to do? "Tighten" it like the manual says and keep your fingers crossed going down the road?

I haven't re-done mine yet. I'll go first and let you know how it turns out. I suspect I'm going to stop at 90% (105 foot-pounds) ---- if it takes that without binding ---- and go from there. 105 is a lot.

Heck, the torque for a 1/2-20 lug-nut is only about 65 foot pounds as I recall.

Ron D.

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

1951 M38 Unknown Serial Number

1951 M100 Dunbar Kapple 01169903 dod 5-51

“The only good sports car that America ever made was the Jeep."

--- Enzo Ferrari

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

Actually the M38 manual does not specify the torque for lug nuts but since they are both carburized and case hardened and one is parkerized (coatings) they should be considered grade 5 so it looks like the standard chart calls for 92 to 101 ft lbs!Heck, the torque for a 1/2-20 lug-nut is only about 65 foot pounds as I recall.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php