Page 11 of 21

Posted: Mon Mar 28, 2022 11:27 am

by Naugha

Brian.

Yes. I bought the ‘Greek’ tail light harness.

https://www.ebay.com/itm/171257498909

So, would using the older ‘two plug’ light switch allow me to use this tail light harness ??

Let’s also talk turn signals.

In the past Wes mentioned ‘Saturn Surplus’ as a source for the end plugs needed to build the turn signal harness that was later used in the retrofit of solid state turn signals to M jeeps..... sorry, I will need to go back check all the ID numbers.

The thing is, Saturn says they no longer carry those turn signal harness plugs.

Any idea where I could find the plugs or the harness?

I have the switch and just ordered a flasher but need the harness.

Posted: Mon Mar 28, 2022 11:45 am

by Naugha

Ron. The head stud length and other issues have been added to my ‘things to worry about’ list.

I really, really want to put the radiator back on, drop in the tub and bolt on the gingerbread.

April’s jeep looks like a jeep. My jeep looks like a skeleton.

Posted: Mon Mar 28, 2022 11:56 am

by RonD2

Naugha wrote:The thing is, Saturn says they no longer carry those turn signal harness plugs. Any idea where I could find the plugs or the harness?

This one?

https://www.eriksmilitarysurplus.com/elcocplfor3l.html

Posted: Mon Mar 28, 2022 12:31 pm

by Naugha

Ron.

Here is a thread that mentions the plugs needed to build the solid state wiring harness along with all the details.

http://www.willysmjeeps.com/v2/modules. ... ic&t=12548

Still struggling with wiring harness version & turn signal mod decisions.

Some say that an indecisive mule, when presented with two identical containers of oats (or whatever mules eat) will starve to death.

RickG may be able to tell us more about the phenomenon.

Posted: Mon Mar 28, 2022 12:43 pm

by RonD2

Pretty sure Erik also has those smaller connectors here

https://www.eriksmilitarysurplus.com/comsfortusis.html

https://www.eriksmilitarysurplus.com/cofortusiflc.html

Along with other military turn signal stuff.

Can't help with the mule. Maybe he's constipated.

Posted: Mon Mar 28, 2022 2:30 pm

by RICKG

Naugha wrote:Ron.

Some say that an indecisive mule, when presented with two identical containers of oats (or whatever mules eat) will starve to death.

A smart mule will eat both..

Posted: Mon Mar 28, 2022 9:12 pm

by wesk

Don,

I bought studs that were ‘supposed’ to fit the M38 head including the two very long ones. I am bad about trusting too much in ad descriptions and not checking the manual.

Maybe the nuts can be torqued another thread or so ????

Maybe add some thread lock????

Best always is to first use the ORD 9 and determine the applicable ORD part number, Manufacturer's part number, Federal Stock Number and if listed the dimensions.

Then shop for the needed part.

The industry standard of a MINIMUM of 1 1/2 threads showing after the nut is for safety reasons and should always be followed. People new to the mechanical world and it's rules often try to rationalize their deviations from these rules. These folks eventually pay dearly for their deliberate deviations.

The industry standards include requirements for thread locker in certain situations. But threadlocker is not a license to ignore physical limitations and prohibitions.

Posted: Tue Mar 29, 2022 6:45 am

by 4x4M38

Here’s the connector for the military flasher:

https://www.ebay.com/itm/165279683000

Posted: Tue Mar 29, 2022 6:51 am

by 4x4M38

Here’s the flasher that connector screws into:

https://www.ebay.com/itm/165115119367

Posted: Tue Mar 29, 2022 7:13 am

by 4x4M38

Don,

In answer to your earlier question. Yes, if you use the two plug Bendix light switch you plug the “Greek” harness into the smaller socket and that is all the wiring for the rear lights and trailer. Less the trailer connector itself with pigtails and connectors.

Assuming no turn signals.

That’s how she came from the factory.

Turn signals. Remember the M38 and A1 did not come from the factory with turn signals. They were a retrofit if installed at all. So the factory wiring did not account for turn signals.

As Wes mentions on his Turn Signals pages there were three types of signals installed. If you want them it will be your call as to which system you put in. They all have advantages and disadvantages.

If it were me, I would build/buy the front wiring harness and other necessary wiring to put it back factory. You have the rear harness. That way you can get the vehicle up and running.

When you get ready to install signals, just follow the directions the Army supplied to do so with the version you pick. They did not take the vehicle apart to install them, so it’s not terribly difficult.

That’s what I would do.

Just my two cents.

Take care,

Posted: Tue Mar 29, 2022 11:14 am

by 45auto

I had the same problem with the longest head stud. Unless you are buying NOS hardware, the dealer's stock "off the shelf" hardware. The military uses lengths that are not industry standards. I'm not looking at the manual, but I believe the studs are measured to something like a 16th of an inch. Bolts and studs off the shelf are to 1/4, 1/2 and 3/4 of an inch. in smaller sizes you can get 3/8 and 5/8 sizes.

I bought grade eight studs to the nearest size longer and cut it down to size. The hardest part was getting the dome and sight taper on the end of the stud. I practiced on some lesser bolts before cutting the stud to size.

What's needed to make the studs are:

A ruler for measuring thread length on bolts. I used a machinist ruler just for measuring thread length.

A sanding disc to make the bevel dome on the end of the stud. I used a 4 1/2-inch grinder with a fine grit pad.

A sharp hacksaw blade.

A 1/2" drill to spin the stud to give the dome a consistent and finish look.

A die to smooth and blend the threads at the end of the stud.

Its a bit of trouble and work but the end results was spot on!

Posted: Tue Mar 29, 2022 12:08 pm

by wesk

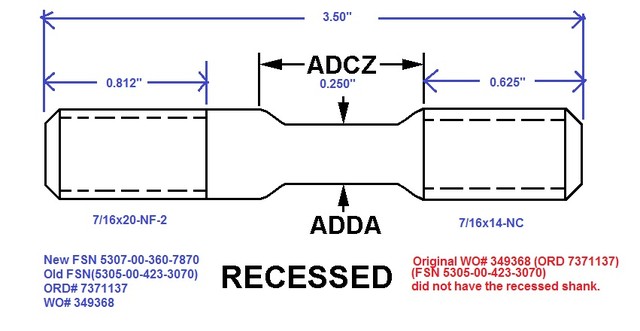

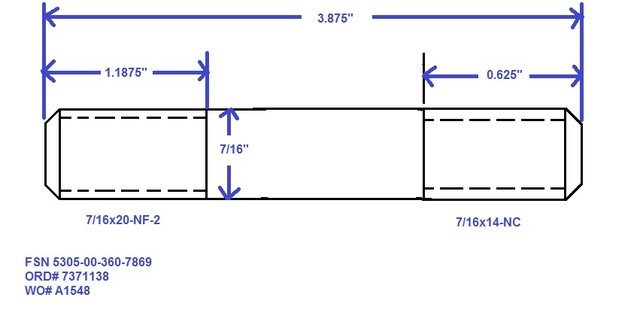

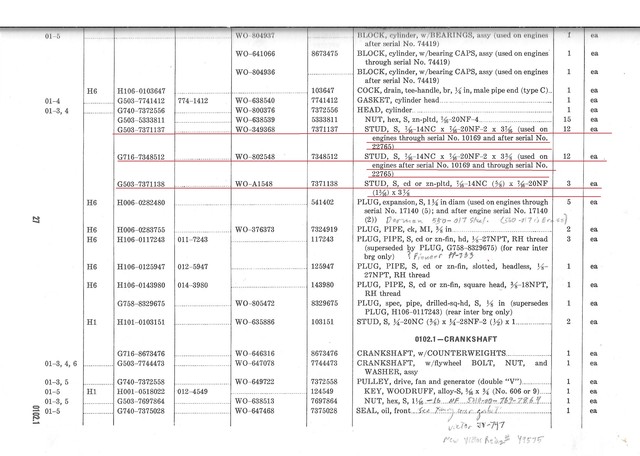

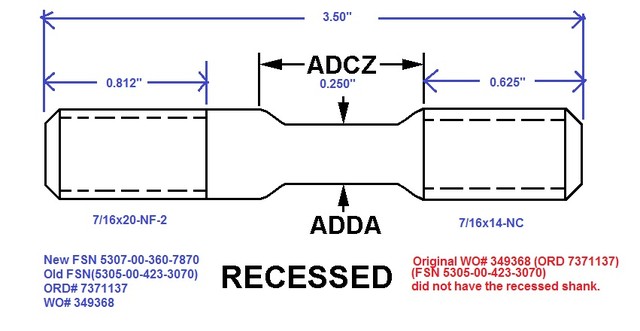

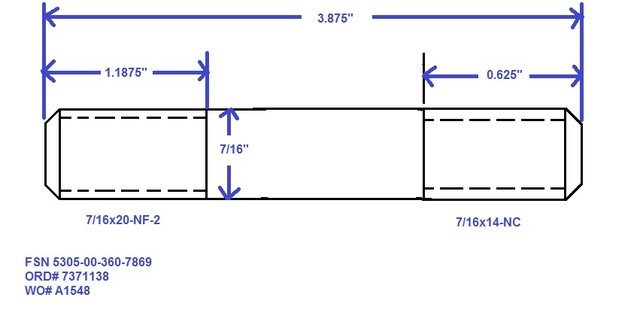

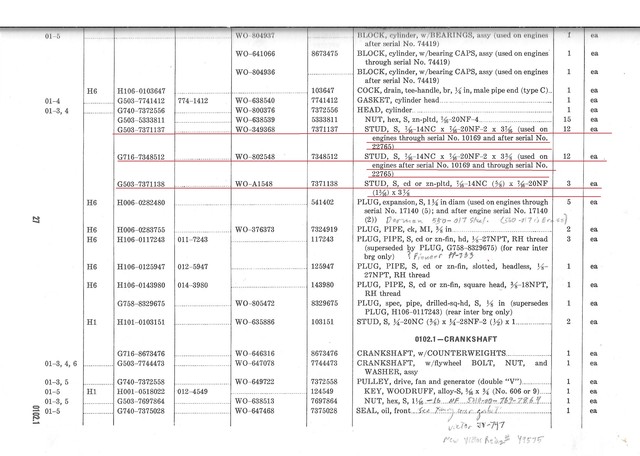

As mentioned above there are slight variances between studs producured by Willys during L134 manufacturing and the military ORD#/FSN studs used in the military logistics system as spares. Here are the dimensions of the Willys produced studs:

Original Willys short stud. Keep in mind there is a second short stud in the ORD 9 that was only used on a short batch of L134's.

Original Willys long stud.

ORD 9 listing for the studs

Posted: Wed Mar 30, 2022 12:46 pm

by Naugha

I count seven short studs that need to be replaced with something two or three or four threads longer. I will not worry about the other studs that may be a tad longer than mil spec.

After cooling down a bit,

, I accepted the situation, resolved to pull the head, take the risk of screwing up something, measure the studs I used, source some slightly longer studs and make it all go away. Far away.

But then, being a sucker for shortcuts, I opened a can of internet worms by reading about how some folks replace unwanted studs one at a time without removing the head. I began having the fantasy of an ‘easy fix’ but thought it best to check in with HQ before I venture into yet another disaster.

I have the socket tool that grabs a stud and helps torque it into the block but I think that gizmo is usually used at the midpoint ridges of the stud. Not sure if that tool works on the upper most part of a stud, especially concerned I can damage the new stud when seating it into the block.

Thread sealer would probably be re applied to the new studs. No problem.

The big debate is over possible damage to the head gasket.

Some say if the head is flat (my head & block were decked) there should be no problem.

Some say pull the head, replace the studs & head gasket or you will be replacing the HG soon.

Some say, “So what. If it works it works. If not, later you replace the HG, no bigly.”

Posted: Wed Mar 30, 2022 1:18 pm

by RonD2

Naugha wrote:I have the socket tool that grabs a stud and helps torque it into the block but I think that gizmo is usually used at the midpoint ridges of the stud. Not sure if that tool works on the upper most part of a stud, especially concerned I can damage the new stud when seating it into the block.

Don,

Studs (by themselves) aren't torqued into the block. The nut on the stud is what gets torque. Pretty sure the tool you describe is a stud REMOVER. Not for installing them. Studs (with sealer) are simply hand threaded into the block until they bottom out. I presume before you put the head on you inspected the threads in the block (not worn or wobbly), and chased them?

I see no reason why you can't remove one or two studs at a time and either install the correct stud or swap a long for a short without damaging the gasket. As I said before, just make sure to seal them in the block again and torque the nut to spec before moving on to the next one. Torque value in the manual for the nut on the stud is given dry.

Now is the time to do this. The block never had coolant in it for the corrosion process to start, so they should come out pretty easy. It may help getting them out by going to the hardware store and buying a couple of thin "jam" nuts to double-nut the stud out.

Posted: Wed Mar 30, 2022 1:59 pm

by Naugha

The block had a snapped stud or two removed, was decked and passed rebuild shop inspection for no cracks.... I think the threads are OK.

Will give it a go.