Page 3 of 9

Posted: Mon Mar 04, 2013 4:52 am

by RommelJuan

pickle wrote:

A couple of parts that would be great to repro and make available are the license plate bracket that was located on the M38 CDN underneath the front bumper, and the other that is put on the back drivers side rear. (I think that there is one in Hawkshadow project posts). Also, if you are retooling a tub for the Cdn unit, the also had a bracket for the convoy light that they had to shine underneath against the rear end of the back axle.

Mk

please show me pictures

Posted: Mon Mar 04, 2013 9:19 am

by rgmutchler

Rommel,

Like several have said I am glad to see that you have posted on the board and are interested in seeing what improvements can be made on your product. I am in the process of rebuilding an M38 body and have tried some of your products, specifically I purchased the right and left lower cowls made by MD Juan. My experience with the fit of these panals has not been satisfactory. I wrote a review for the parts review section of the forum. I am including in this post what I wrote about the MD Juan lower cowls hoping that it might specify some of the problems that are encountered on fitting your parts. I don't know if there is a mark on replacement panals that would specify when they were made as later panels might have improvements. As a customer one problem is that when we purchase a replacement panel we don't know what production run it came from or how old the replacement panel is. If the supplier has a surplus of a particular panel we don't know if we are getting the new and improved version unless MD Juan has a mark on the part indicating that it is an improved version. One of the panels I bought was in the gray primer and one in the red primer. I understand that the serial numbers on your tubs can tell us that.

Below is my review of the lower MD Juan lower cowls.

Again I appreciate your stepping up and contacting your customers directly and I only post my review of your parts as constructive criticism,

Review:

MD Juan

1. The height of the panel is at least 1/8 inch short.

I measured from the front edge of the step upward using a square, the height to the top of the panel was 14.5 inches. The original panel was between 14 5/8 and 14 11/16. I measured both left and right MD Juan cowls and the measurement was the same, 14.5.

2. The step is made wrong.

I had purchased a NOS front floor/firewall panel. After installing it in the body I attempted to fit the MD Juan left lower cowl. It would not match up due to the hat channel on the floor that runs underneath the step. The hat channel was either too long or the step on the MD Juan panel was mis-shapened. I compared measurements and angles for that part of the hat channel with the remainder of the hat channel on my removed floor and found the original was a match in all respects for the NOS one I had purchased.

The same problem existed for the right cowl but I didn’t spend as much time on it as the left.

3. The gusset for the upper corner where the fender bolts is attached making it hard to properly fit the panel with the firewall.

There is a gusset in the top corner of the lower cowl. This gusset has a hole cut in it for the wiper vacuum line and has a cage nut on it for the upper fender nut. This gusset is included and welded to the MD Juan panel. However it causes a problem because that gusset, at least on my original parts, not only is attached to the cowl but overlaps the lip of the firewall to get the panel and firewall to fit and position correctly. It appears to me that this gusset was added to the body at the factory after or at the same time the firewall and cowl are mated up.

4. The original panels, in fact the whole top portion of the jeep body had a lip that is bent down into a U shape and then another piece of U shaped channel is pushed or secured into the channel that finishes off the top of the panels. The MD Juan does not have the second U channel but it does appear to be made from a heavier gauge metal.

5. MD Juan attaches the cowl support that fits up under the upper cowl. The support does not look the same as the original and I think it inhibits fitting the part.

6. Lastly but very important the angle of the front edge of the cowl where it is supposed to meet the fender is wrong. If you bolt up at the top the gap at the bottom seems to be about 3/16 to ¼ inch. I compared it to poster board templates I made of the side of the jeep before I started taking it apart and to the original cowl.

Ralph Mutchler

Posted: Mon Mar 04, 2013 11:37 am

by RommelJuan

Will work with the team and get back to you right away

thanks!

Posted: Mon Mar 04, 2013 1:27 pm

by Hawkshadow

RommelJuan wrote:pickle wrote:

A couple of parts that would be great to repro and make available are the license plate bracket that was located on the M38 CDN underneath the front bumper, and the other that is put on the back drivers side rear. (I think that there is one in Hawkshadow project posts). Also, if you are retooling a tub for the Cdn unit, the also had a bracket for the convoy light that they had to shine underneath against the rear end of the back axle.

Mk

please show me pictures

I believe that he is referencing the licence plate holder visible in the following picture on the left rear of the tub. If you would like me to take some more detailed pictures with measurements, just let me know!

Posted: Mon Mar 04, 2013 6:35 pm

by RommelJuan

please show bigger and closer pictures. Thanks

Posted: Mon Mar 04, 2013 8:07 pm

by ECVJeeps

Here is a closer pic of the front!

And the back.

If you would like I could send you the damaged one on the right then you would have an actual item to pull dimension from or reverse engineer from.

Or I might be able to draw up a set of drawings in AutoCAD?

Cheers

Pat Newman

Posted: Mon Mar 04, 2013 9:04 pm

by wesk

Were those license plate brackets installed on the jeep by Ford of Canada, The Canadian Armed forces or a civilian owner? If they were installed by FOC or CAF then are they listed in either of the Canadian IPL's?

Posted: Mon Mar 04, 2013 9:52 pm

by ECVJeeps

I am not sure, however I have removed at least three of these brackets from various M38CDN's that I have salvaged parts from.

Posted: Mon Mar 04, 2013 9:58 pm

by pickle

Thanks Pat, that is exactly what I wanted to show for a picture.

This one, and the front which was attached to the lower front center of the bumper with a hinge so the plate can be folded back, I believe were Ford of Canada. Pat, I think you have a picture of your first jeep with it on it? I can pull mine out and take a picture, but it will be a couple of days as I am in the midst of moving from one computer to another.

as far as the convoy light bracket, I will try to dig something out to show you.

Posted: Tue Mar 05, 2013 4:56 am

by ECVJeeps

I do not have a front one in the shop at the moment, I have had my hands on them before, however the customer always comes first and my last one left the shop with the last jeep I did.

Anyone else have a pic of the front license plate bracket?

Posted: Tue Mar 05, 2013 6:42 am

by ECVJeeps

The following is a few pictures of the Canadian axle convoy light and bracket.

These are bolted to the inside of the jeep frame rail just forward of the rear cross member on the P/S facing the axle.

Because of the location behind the rear tire and under the jeep they are usually found corroded beyond repair or have been removed and thrown away over the years by previous owners.

The same light assembly is found on the M100 Canadian trailers and a metal plate is bolted to the rear floor of the trailer with a small metal tab welded behind the floor support for the axel convoy light.

The Canadian quarter is for size comparison.

Posted: Tue Mar 05, 2013 11:39 am

by wesk

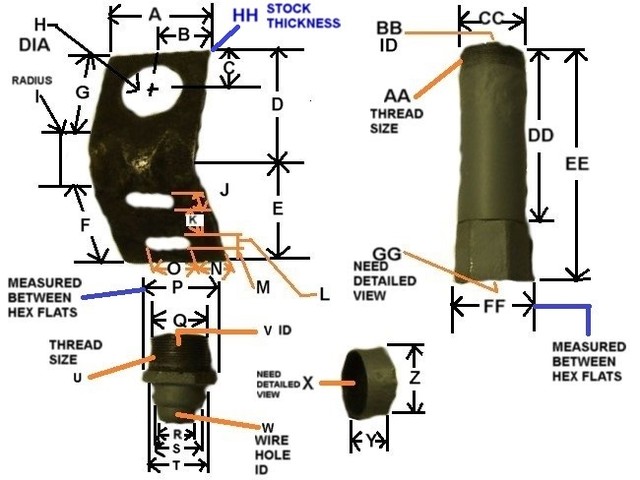

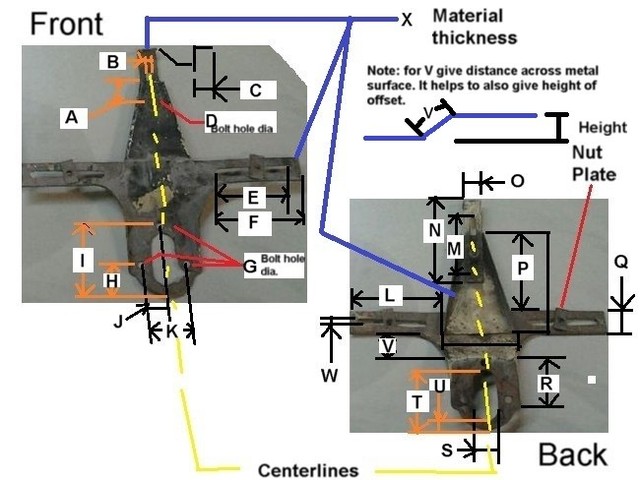

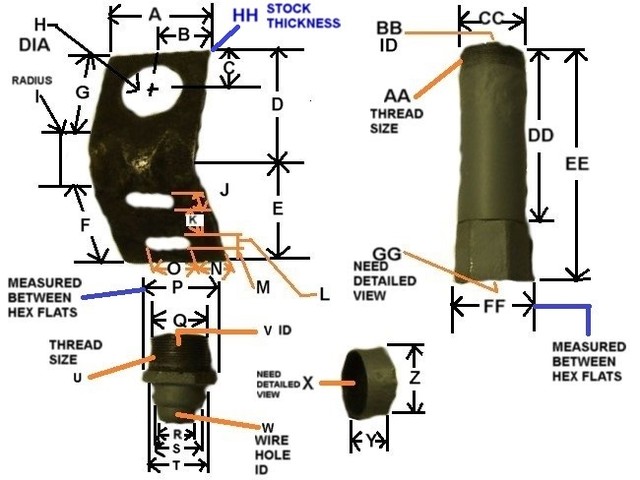

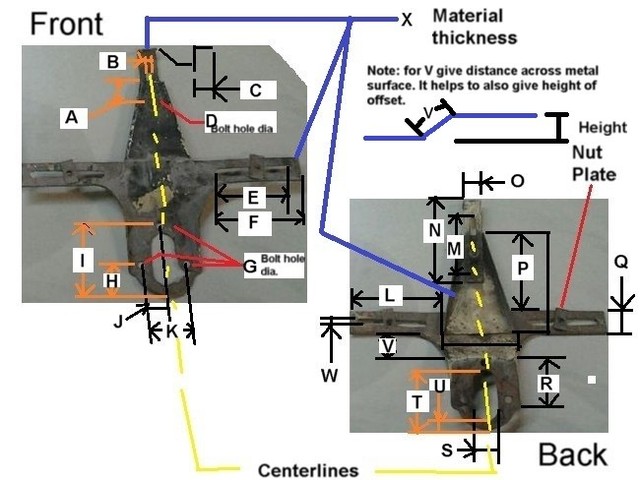

Perhaps we can get some measurements for this:

Posted: Tue Mar 05, 2013 11:48 am

by ECVJeeps

I am sitting in front of my computer with one on my desk, give me a few and I will do up a set of plans.

Cheers

Pat

Posted: Tue Mar 05, 2013 12:24 pm

by wesk

great. This one as well.

Also photos were not close enough to see any stiffening details IE rolled up lips.

Posted: Tue Mar 05, 2013 1:00 pm

by ECVJeeps

I will bring my vernier caliper into work tomorrow and try to finish this.

I will try to get a thread pitch off of it as well.