Frustration has set in. Clouds are darkening. I can feel an evil presence in my garage. I'm at my wits end.

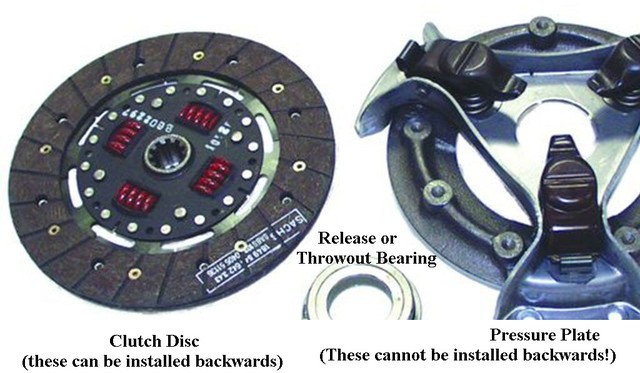

I had a bad throw out bearing which is what started me down this path. I went ahead and had the Transmission and Transfer case rebuilt with the thought that I wanted to replace it all once and be done. While those units were out, i replaced the clutch/pressure plate and throw out bearing. I did not replace the clutch fork, it was in good shape, but did use a new return spring. I resurfaced the flywheel.

After re-installation, I was trying to adjust the clutch as per the manual. I installed a new clutch rod (10 15/16) and welded/drilled the crossover tubes so everything was nice and tight. I replaced all crossover pivot balls....everything from clutch pedal to flywheel was serviced.

During adjustment, I could never get the throw out bearing to stop spinning. In fact, I toasted the new throw out bearing in the process. I'm fairly certain it was bad before installation as it was noisy from the first startup....still.....pretty odd right?

So I pulled the engine, ordered a new bearing and also replaced the pilot bushing in the flywheel.

After re installation, I'm running into the same problem. If I adjust the clutch pedal so that it has 1/4 inch play...or even 1/2 inch play, the bearing will continue to spin when the clutch is released. I can only get it to stop spinning if I grab the clutch cable and push it into the bell housing. It's like there is not enough tension on the clutch fork to release the bearing fully.

What am I missing?

M38A1 throw out bearing won't stop riding the pressure plate

- Willis

- Member

- Posts: 26

- Joined: Sun Sep 13, 2015 6:00 pm

- Location: Harrisburg, PeeAy

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

1 - You installed a new return spring. How did the new spring compare to the old spring before installation?

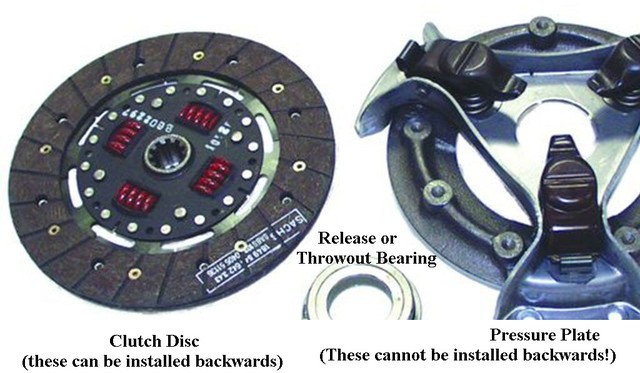

2 - How did the new throwout bearing compare to the old throwout bearing dimensions?

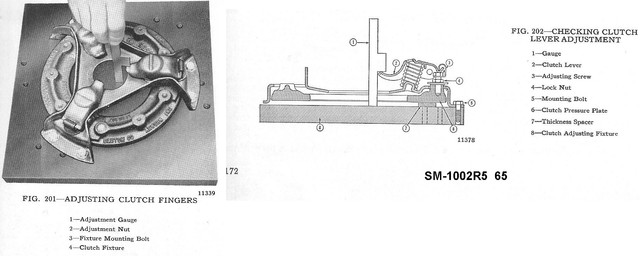

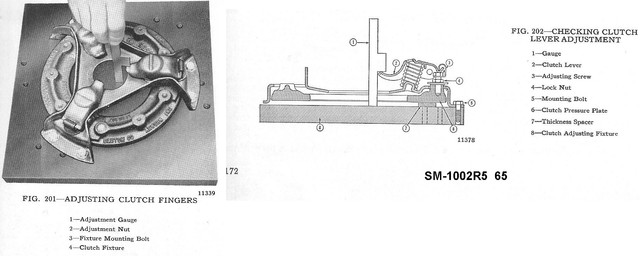

3 - Was the new clutch pressure plate return fingers the same height above the flywheel face as the old pressure plate release fingers?

4 - Was the new clutch release linkage rod the same length as the old one?

If as you say you can push the clutch release cable forward and the bearing stops spinning then there is room for the bearing to move further aft but something is preventing the adequate aft motion or the pressure plate release fingers are too tall.

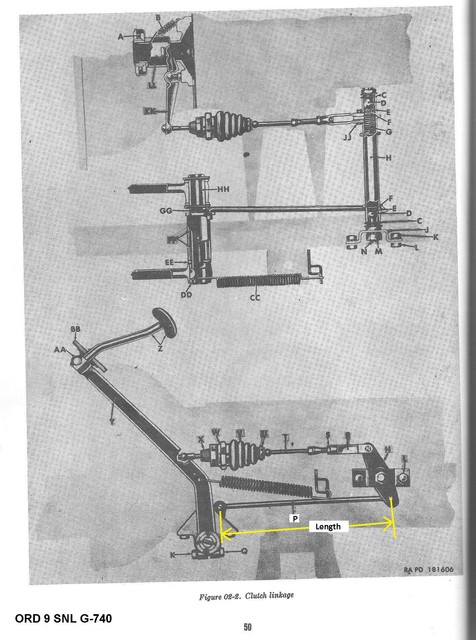

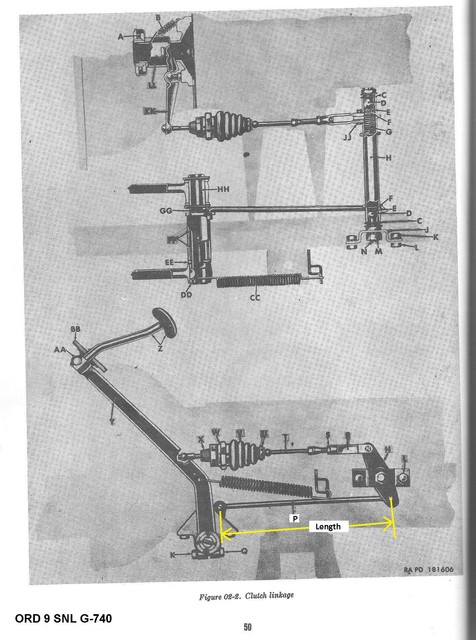

The above photos are from my Mjeeps album. It is the 2nd album in the member's album page.

You will find a lot of additional clutch info in the civvy service manual SM-1002 Rev 5 (1965).

Look in chapter J. http://www.willysmjeeps.com/v2/modules. ... _album.php

As a general note to the entire membership when you are making repairs that are very labor intense you should always gather as much technical data as you can get your hands on. Yes you should always do this but where you spend hours on tasks such as just removing and installing the engine for clutch work you can save the repetitive hours covering the same ground more than once. This is especially true with hobbyist who are not trained / experienced mechanics. Most manuals are written under the assumption that an experienced mechanic is using them. Therefore common tasks associated with a special repair are often times not included in the work description in one manual but are in another. This situation above is a classic example that using the Army TM 9-8015-1 was just not enough since it lacked some information we were able to find in the civvy manual SM-1002.

2 - How did the new throwout bearing compare to the old throwout bearing dimensions?

3 - Was the new clutch pressure plate return fingers the same height above the flywheel face as the old pressure plate release fingers?

4 - Was the new clutch release linkage rod the same length as the old one?

If as you say you can push the clutch release cable forward and the bearing stops spinning then there is room for the bearing to move further aft but something is preventing the adequate aft motion or the pressure plate release fingers are too tall.

The above photos are from my Mjeeps album. It is the 2nd album in the member's album page.

You will find a lot of additional clutch info in the civvy service manual SM-1002 Rev 5 (1965).

Look in chapter J. http://www.willysmjeeps.com/v2/modules. ... _album.php

As a general note to the entire membership when you are making repairs that are very labor intense you should always gather as much technical data as you can get your hands on. Yes you should always do this but where you spend hours on tasks such as just removing and installing the engine for clutch work you can save the repetitive hours covering the same ground more than once. This is especially true with hobbyist who are not trained / experienced mechanics. Most manuals are written under the assumption that an experienced mechanic is using them. Therefore common tasks associated with a special repair are often times not included in the work description in one manual but are in another. This situation above is a classic example that using the Army TM 9-8015-1 was just not enough since it lacked some information we were able to find in the civvy manual SM-1002.

Last edited by wesk on Tue Jul 26, 2016 12:46 pm, edited 1 time in total.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

- 4x4M38

- Jeep Legend

- Posts: 3487

- Joined: Thu May 29, 2014 6:00 pm

- Location: Texas Hill Country

- MODIFIED

- Jeep Enthusiast

- Posts: 353

- Joined: Thu Mar 27, 2008 6:00 pm

- Location: BrOoKlYn

Hi Willis,

Sounds to me that the fingers on your pressure plate may need adjustment.

-Are you certain the clutch cross shaft is oriented correctly?

-Your replacement bearing the same thickness as the orig you removed?

Might I suggest you refer to TM9 8015_1 Engine Clutch manual pg 144. Also have a look at the following to help in your troubleshooting:

https://www.google.com/search?q=pressur ... mjeeps.com

https://www.youtube.com/watch?v=mNWRDvJYMhg

http://www.thecj2apage.com/forums/adjus ... 12516.html

http://www.thecj2apage.com/forums/adjus ... 12516.html

While you'll probably need to re-enter the cavity, I'd mic the Clutch disk for correct face thickness.

Good luck

Sounds to me that the fingers on your pressure plate may need adjustment.

-Are you certain the clutch cross shaft is oriented correctly?

-Your replacement bearing the same thickness as the orig you removed?

Might I suggest you refer to TM9 8015_1 Engine Clutch manual pg 144. Also have a look at the following to help in your troubleshooting:

https://www.google.com/search?q=pressur ... mjeeps.com

https://www.youtube.com/watch?v=mNWRDvJYMhg

http://www.thecj2apage.com/forums/adjus ... 12516.html

http://www.thecj2apage.com/forums/adjus ... 12516.html

While you'll probably need to re-enter the cavity, I'd mic the Clutch disk for correct face thickness.

Good luck

Always Looking for M170 Parts and bits

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

As stated in TM 9-8015-1 page 231 the play is not less than 1 1/4".

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

- Willis

- Member

- Posts: 26

- Joined: Sun Sep 13, 2015 6:00 pm

- Location: Harrisburg, PeeAy

Wes:

1. I replaced the spring for good measure. It was identical to the spring taken out.

2. I couldn't tell. The old one was so bad that it fell apart during disassembly. I do not have it any more.

3. Yes.

4. No. The rod that was in it was shorter. I replaced it with a new longer rod, and shorter cable. I did this because: 1 - From what I researched, the 10 15/32 is the correct rod and 2: I was out of adjustment with the current rod/cable combo.

The old cable, without the yolk, was 11 1/4". When I installed the new rod, i ran out of adjustment with the old cable and deduced that I needed a shorter cable. The new Cable, without the yolk, is 10 1/4" and gave me the adjustment I needed to get the clutch pedal to 1/4" free play.

Modified:

1. I am triple checked certain it is oriented correctly.

2. See #2 from above

Thanks for the links - I'm researching them

I went out and checked to see how much backwards movement the carrier/bearing had. I couldn't move it backwards by hand, but when i used some leverage (screwdriver), I was able to move it back 1/4".

1. I replaced the spring for good measure. It was identical to the spring taken out.

2. I couldn't tell. The old one was so bad that it fell apart during disassembly. I do not have it any more.

3. Yes.

4. No. The rod that was in it was shorter. I replaced it with a new longer rod, and shorter cable. I did this because: 1 - From what I researched, the 10 15/32 is the correct rod and 2: I was out of adjustment with the current rod/cable combo.

The old cable, without the yolk, was 11 1/4". When I installed the new rod, i ran out of adjustment with the old cable and deduced that I needed a shorter cable. The new Cable, without the yolk, is 10 1/4" and gave me the adjustment I needed to get the clutch pedal to 1/4" free play.

Modified:

1. I am triple checked certain it is oriented correctly.

2. See #2 from above

Thanks for the links - I'm researching them

I went out and checked to see how much backwards movement the carrier/bearing had. I couldn't move it backwards by hand, but when i used some leverage (screwdriver), I was able to move it back 1/4".

- 4x4M38

- Jeep Legend

- Posts: 3487

- Joined: Thu May 29, 2014 6:00 pm

- Location: Texas Hill Country

- wesk

- Site Administrator

- Posts: 16443

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

Willis,

Before I would consider removing that engine again I would:

1-Adjust free play to correct spec.

Still no go?

2-disconnect the push/pull rod. (Item P in clutch linkage illustration)

Still no go?

3-Pull the engine.

Before I would consider removing that engine again I would:

1-Adjust free play to correct spec.

Still no go?

2-disconnect the push/pull rod. (Item P in clutch linkage illustration)

Still no go?

3-Pull the engine.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

- Willis

- Member

- Posts: 26

- Joined: Sun Sep 13, 2015 6:00 pm

- Location: Harrisburg, PeeAy