Page 1 of 3

M38 Gauge Testing: Dead or Alive?

Posted: Fri Jan 28, 2022 5:42 pm

by Naugha

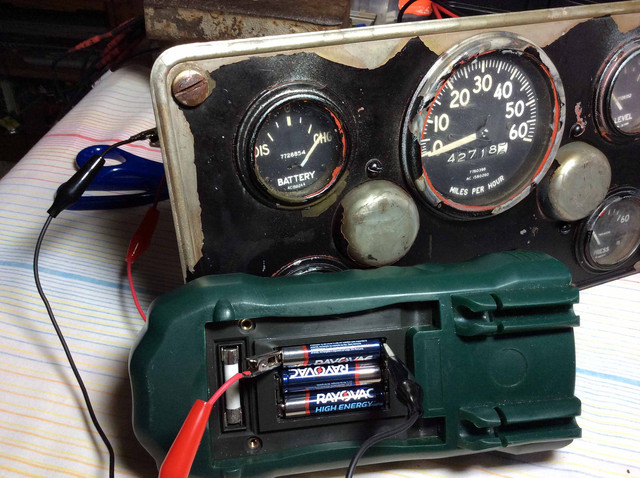

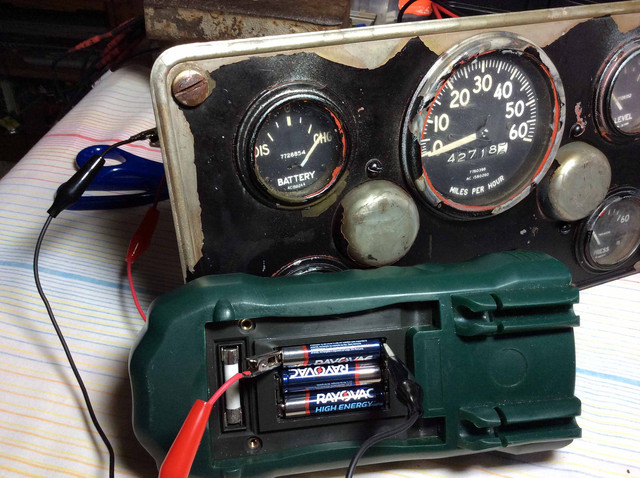

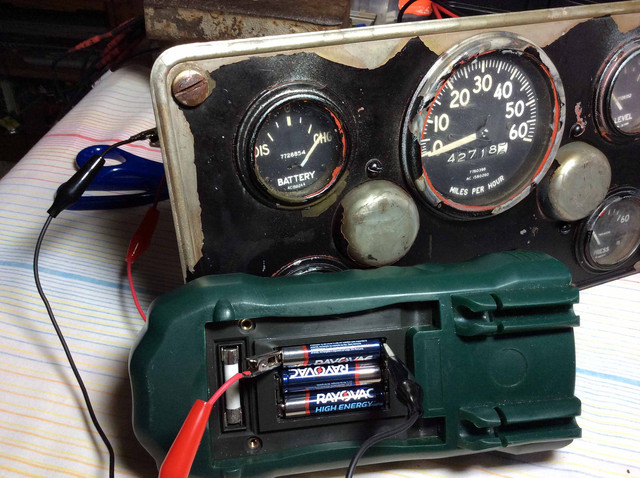

I wanted to bench test some gauges using a 'dead or alive' small battery connection suggested in a thread I found.

“Bench testing a Gauge: Remove all wires from the gauge to be tested. Make sure the gauge terminals are insulated from the housing. To check a Fuel, Oil or Temperature gauge, connect a D cell battery to the gauge terminals. The gauge should read about 1/4. If it does not, the gauge is bad. To check an amp meter, measure the resistance between the two terminals. It should be very close to 0 ohms. The gauge pointer should be centered. “

https://cj3a.info/sibling/utilgauge/gauge3.htm

I know this is not:

http://willysmjeeps.com/downloads/instruments.pdf

but I am looking for a quick way to spot a DOA gauge.

The Ammeter looked good, showing needle deflection based on polarity.

The other gauges gave results that require help at interpretation.

I noticed that if you rotate the gauges (upside down) the needles move to the max. reading. Does this tell anything about the 'dead or alive' status?

Now other stuff. The Temp gauge will not respond to the battery current unless you thump it a few times ... then the needle pegs.

Then the really strange one (to me) .... if you attach the battery (9v) to the 'Level' and 'Press' gauges ... when in the vertical position... no joy.

But if you rotate the Level & Press gauges so as the needle is above the minimum notch ..... the needle pegs.

]

Has anything I presented here help establish the ‘dead or alive’ status of the gauges .... and can/should anything be done to improve the performance of the gauges.

As always, plan B will involve money and questions aboutnwhatnto buy.

Posted: Fri Jan 28, 2022 6:07 pm

by RonD2

Hi Don,

Unsure about your test method (without seeing the thread you reference), and without having to drive your jeep upside down or account for gravity, it seems to me that any needle deflection could prove the meter guts might still be ok?

Either that, or maybe a bigger hammer (prominent tool in the photos)?

Just say'in my opinion......

Good luck!

Posted: Fri Jan 28, 2022 6:10 pm

by Naugha

Hi Ron. I am in the process of editing the post to add some details.

Posted: Fri Jan 28, 2022 6:14 pm

by RonD2

Yes, details matter.

Patience.........sorry.....

Btw, you take great photos.

Posted: Fri Jan 28, 2022 6:34 pm

by Naugha

Ron. Try it now. Sorry, I should compose off line then copy paste into the thread ... but that would be smart.

Insect photography was a past hobby I picked up from my UofF entomology professor. Then there was astrophotography using my really big arass scope in the small observatory I built .... oh, yeah, underwater cave diving videos. Did some wedding photography.

But now I just use the ‘ol iPad and cull out the bad stuff.

Any input on the gauges ?

Re: M38 Gauge Testing: Dead or Alive?

Posted: Fri Jan 28, 2022 6:55 pm

by RonD2

Don, not sure what that sentence fragment means.

If you did those tests, what resistance measurements did you get? Pass? Fail?

I think the real test of any guage is in actual operation. I'd bet the Army pitched gauges into the ashcan by the dozens as not economical to repair. I wish mine were working originals.

For example, as long as you have a known good test oil pressure gauge hooked up when you first start your motor all else is secondary and can wait until you get around to it. No oil pressure being a big deal.

From there, I'd concentrate on the ammeter (or voltmeter if you decide). Then temperature gauge (keep an eye on the radiator). And finally the fuel gauge.

Just my nickels' worth.

"Dead or Alive" is an old TV show from my youth that I watch on the Hero's and Icon's Network every morning at zero dark thirty that stars Steve McQueen. They don't make them like that anymore.

Posted: Fri Jan 28, 2022 8:51 pm

by Naugha

I think the real test of any guage is in actual operation. RonD

I can go with that, but the jeep is still in parts and I was hoping to find a way to cull out DOA gauges before populating the cluster. So, do you just pay your nickel and take your chance ??

I also have two speedos that are both cha-cha .... but even with money to do whatever is best needed ...... how the heck does one fill in the circles with reliable parts ? What should I put in those holes.?

Sure, I have the list of ‘proper’ M38 gauges/speedos but that’s really not the issue..... Lots of gauge stuff out there. Lots of stuff that says NOS but what NOS are they talking about? Military ??? Repop ?? Take off cha-cha???

Such a seemingly simple question. NOT !! What reliable gauges/ speedo should go in those holes so I can get on with the project. NOS/repop/ Take off / whatever

... and the senders are another big issue.

.

Sorry. Sometimes I get this way.

Posted: Fri Jan 28, 2022 9:12 pm

by wesk

The new test program you are trying to adopt is a real waste of your time. The Army solved the test format years ago. Just use the good old test program that we all know already works. If you simply must have a new program then start by documenting the exact detailed processes and expected results. This gives everyone a map they follow along with your adventuristic new idea program.

The Army wanted throw away gages so they save shop labor for more important tasks. Anytime you find a rolled edge bezel retaining gauge guts it is your first clue they are not easily rebuildable.

As for the speedo's there a guy with a shop in Washington State that rebuilds them and bench checks them.

Posted: Fri Jan 28, 2022 9:13 pm

by RonD2

So, do you just pay your nickel and take your chance ??

Don, Don, Don, take five....I always seem to be wanting to talk you off the cliff.....

This can't be a news flash to you at this point. The entire M38 hobby (or whatever you want to tell your spouse or yourself) is all about taking chances. It just depends on how much money you want to spend and not count.

Take it one step at a time is the best advice I can offer. If you're hard over dedicated to original M38 with no compromises then it'll take longer and cost more before you ever get on the road. Naturally, some things can't be compromised, especially if you want to live.

If you'd like to make a few compromises in the short term to get driving sooner, it'll probably still cost a bunch but won't take so long. You can "circle back" to some details later as you manage them. "Later" could mean days, months, or years (but hopefully not decades or drift into your estate).

You already know that some M38 parts aren't getting any more abundant or any cheaper. I think that list gets longer by the minute. You decide.

Anything I can do to help, I certainly will. Make your post questions prefaced by "anybody except RonD" and I'll stick a sock in it.

I try to "keep the faith, baby" as much as I can with the tech manuals and my wallet. Good thing I like baloney.......

Posted: Fri Jan 28, 2022 10:32 pm

by Naugha

I am not tied to using the old gauges that are in my pile of parts.... just thought that would be one place to start.

I would like to use original parts when possible but understand that is not always the best choice.I very often don’t know the best choice which I think is why I am here. The project is full of compromises with more on the way.

I am open to any suggestions based on successful solutions to populating the cluster but if that is not how this works then OK.

The standard test procedures looked to me like something you do on an operational vehicle and I was looking for something else when I came across that thread.... not my test... something proposed by someone who thought they had a quick way to decide on tossing or keeping a gauge.

Perhaps old take off parts are not worth the effort. Perhaps knowing what to do is not knowable and direct solutions not possible.

The jeep will need a gauge cluster so I will keep looking.

Posted: Sat Jan 29, 2022 7:30 am

by 4x4M38

Hi Don,

One of Wes’ recommendations for a “driver” is use mechanical oil and temp gauges. Plenty out there at reasonable prices. Easy enough to paint the housings.

If you really want to test the takeoffs use the MV text procedures. It’s not difficult, just requires a few minimum items.

As far as the speedos. Do they actually work, and you want to clean them up?

They are simply tested by turning the drive with a hand drill. Just remember the drive rotated counterclockwise.

Take care,

Brian

Posted: Sat Jan 29, 2022 12:33 pm

by mdainsd

Don, Do you make it to the MV meets? This stuff is all around if you look.

The speedometers are the easiest, you can do a basic test on them standing at the sellers place. If you are determined to have the speedometer with the exact part number the search gets longer. But if you can deal with a military speedometer of that time range they are plentiful. (Sidebar. Im trying to find a speedometer for my slat grille. People are asking 750 bucks for those and they need rebuilding).

There is a military mechanical oil pressure gauge (60 psi) that looks nearly identical to the electric one in M38s. I have thought about those but all my original gauges work just fine. Search the big online auction site for "Military oil pressure gauge", and see what pops up.

Your ammeter looks to be good to restore and install.

Posted: Sat Jan 29, 2022 2:57 pm

by Naugha

Hi to all..... touching on a few things from above.

* Yes, I am going to a MVPA rally in March with my shopping list & wallet.

* Yes. The ammeter looks like it works.

I had read the ‘Troubleshooting for Military Standard Instrument Cluster Gauges’ download but was unsure about its application on take off parts.

* Are those gauge troubleshooting procedures intended to be used on an otherwise functioning vehicle .... or can the procedures also be used to bench test stand alone units?

* Is there another specific document devoted to testing gauges that are not mounted on the vehicle?

* Sounds like there are some folks successfully using their original gauges.

* The speedo that came with the jeep ‘spins up’ but the face and odometer numbers are shot to heck. The other speedo looks great from the front (may be a repop) but the back part that connects to the cable is cracked off... seems odd that such a pristine unit would snap off in the back.

Don

Posted: Sat Jan 29, 2022 10:12 pm

by JBJeep

wesk wrote:

As for the speedo's there a guy with a shop in Washington State that rebuilds them and bench checks them.

The folks at Midwest Military said they could fix the speedo for my M38A1. They had me ship it to a shop in Oregon. Same shop perhaps?

They can do a range of work from simple repairs, replacing the plastic lens (what mine needed), to complete overhauls.

If you can live with a later gauge with a "MS-XXXXX" number on the face instead of an older, period correct gauge with a part number, you can get a repop or (I think) NOS for <$100, much less than the cost of a overhaul.

Posted: Sat Jan 29, 2022 11:04 pm

by wesk

I had read the ‘Troubleshooting for Military Standard Instrument Cluster Gauges’ download but was unsure about its application on take off parts.

Most of the tests can be performed with gage removed. You simply replace ignition switch on with a 24 V battery source and any standard single pole/single throw toggle switch. Yes this type of troubleshooting requires a basic knowledge of instrument systems, the correct testers and a wee bit of common sense. As for what you are calling "Takeoff Parts" keep in mind the instrument cluster is removed from the dash for the bulk of these tests and individual gauge leads disconnected or jumpered as stated in the test procedure. The simplist way to do what you are trying to do is lay the assembled instrument cluster on your work bench. Then lay the three senders Oil press/water temp/Fuel Quantity on your bench. Then with a good set of jumper wires with quick clips attach the senders to their gauges and ground the sender bodies to the 24V battery negative cable. Run a red wire from the 24V battery's positive post to the toggle switch and then connect the toggle switch to your instrument spider harness. If you want to also duplicate operating conditions you simply do the following with the 3 senders: 1 - Fuel move the float up for full and down for empty. 2 - Water temp, immerse sender in a pot of water on a portable burner and heat water to show temperature on gage matches the thermometer in the water. 3 - Oil Press you just connect sender to gage + & 24V bat - and add a small handpump with oil in it and an inline 0-60 mechanical pressure gage and compare mechanical gage reading to electric gage reading.

* Are those gauge troubleshooting procedures intended to be used on an otherwise functioning vehicle .... or can the procedures also be used to bench test stand alone units?

See above answer.

* Is there another specific document devoted to testing gauges that are not mounted on the vehicle?

NO

* Sounds like there are some folks successfully using their original gauges.

Yes

* The speedo that came with the jeep ‘spins up’ but the face and odometer numbers are shot to heck. The other speedo looks great from the front (may be a repop) but the back part that connects to the cable is cracked off... seems odd that such a pristine unit would snap off in the back.

Since that drive sticks out on the back of the gage then it would likely get damaged if the gage is dropped and the drive input hits the floor first.

I would suggest you team up locally with a sharp 24V electrical and instrument technician and have him walk you thru these tests.