Page 1 of 1

M38 engine leakdown test results

Posted: Sat Apr 22, 2023 7:53 am

by JeepdaddyRC

Have been chasing an assumed vacuum leak.

Took a closer look at the engine.

Appreciate your help interpreting the cylinder leakdown test:

#.....In psi...Out.psi....Loss.......Location of escaping air

1.......80........72........10%.......Oil fill tube

2.......80........30........62%.......Oil fill tube, tail pipe, #3 and #4 spark plug holes, antifreeze was pushed up in radiator

3.......80........68........15%.......Oil fill tube, #2 spark plug hole, antifreeze pushed up in radiator

4.......80........66........17%.......Oil fill tube

Posted: Sat Apr 22, 2023 10:31 am

by RonD2

.......for continuity to save from re-treading the same ground (and in two forums here and G503), this is a continuation of a 5-page thread to solve the same problem --->

http://willysmjeeps.com/v2/modules.php? ... ic&t=13523

Did you also do a compression test? Results?

Posted: Sat Apr 22, 2023 11:39 am

by wesk

Your leakdown test offers much more info than a compression check. I have been in aircraft maintenance since 1966. That industry quit wasting time with compression checks during WWII and almost 100 % now use the leak down test only. The reason for the switch was labor time. Why do a compression check if when it shows an issue you must then do a complete leak down test.

2......80......30......62%......Oil fill tube, tail pipe, #3 and #4 spark plug holes, antifreeze was pushed up in radiator

#2 is clearly a problem. What you describe is a normally associated with a cracked block. Also you mention a hint of exhaust valve leakage which also needs further inspection. #3 may only be sympathetic with # 2 on the radiator pressure.

I would start with the easy part and check out the #2 exhaust valve by pulling the side cover and see if it is sticking or is adjusted too tight. If you can get the valve to close fully and redo the leak down check and radiator coolant is till rising and the reading is still more than 10% lower than the highest then pull the head and look for the crack.

Posted: Sat Apr 22, 2023 3:47 pm

by JeepdaddyRC

Removed side cover with #2 cylinder at TDC. Findings:

- confirmed 0.016 intake and exhaust valve tappet clearance

- several more threads showing on exhaust valve tappet adjuster

- exhaust valve spring keeper is 1/4 inch higher than the intake spring - suggesting it is partially open?

- lowered the adjuster to insert screw driver blade between tappet and valve

- valve moves up freely but does not return to same level as intake spring keeper

Sprayed PB Blaster thru plug hole. Unclear what is holding it up,

Suggestions?

Posted: Sat Apr 22, 2023 8:22 pm

by wesk

Time to pull the head.

Posted: Sun Apr 23, 2023 4:40 pm

by JeepdaddyRC

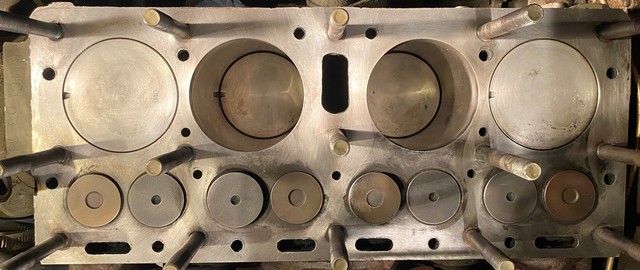

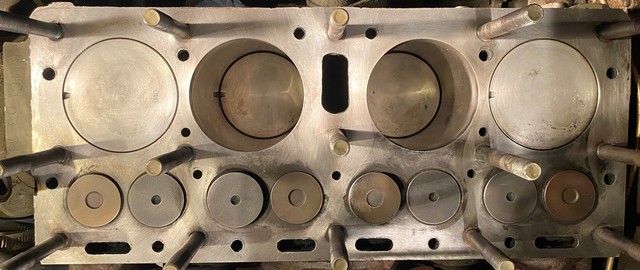

The head is off. To my surprise, the #2 exhaust valve is not stuck open.

Pistons stamped 0.40.

Is the head gasket compromised between #2 and #3 cylinders and to the water jacket?

Needs cleaning, but no visible cracks to naked eye.

Should head go to a machine shop for magnafluxing?

What else should i look for, or do, while head is off?

Thanks for your help Wes, couldn't do this without you!

Posted: Sun Apr 23, 2023 10:51 pm

by wesk

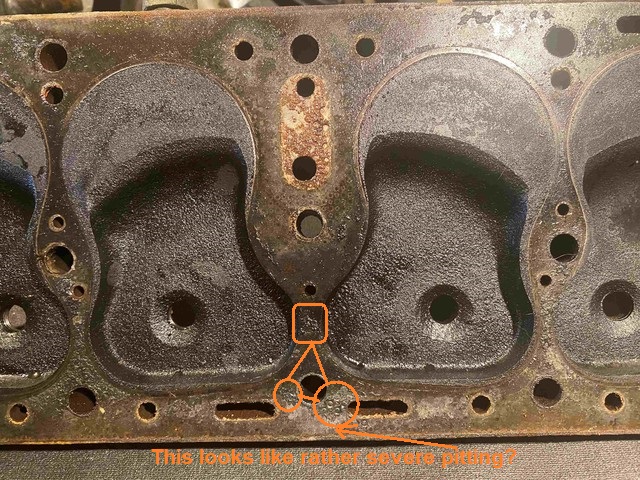

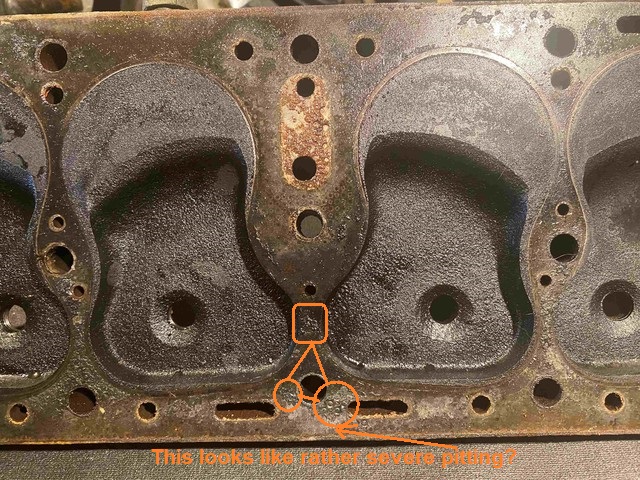

It looks like you have severe pitting in three locations between #2 & 3 cylinders on your head which could cause your symptoms.

Posted: Mon Apr 24, 2023 9:15 am

by JeepdaddyRC

They look like carbon deposits between #2 and #3 cylinders (square in photo). Blown head gasket?

The valves and pistons do not appear cracked, broken or burned - but I am no engine expert.

If you see a blown head gasket, and that could explain the symptoms, is first step reassembly and testing?

Do you like the Felpro or 7285B or MWM copper head gaskets?

Posted: Mon Apr 24, 2023 10:04 am

by wesk

I have used the copper sandwich for years. The only little issue is you must retorque after first run. Not a big deal but many people abandon proven old fashion reliability for new ideas.

Your first step is a thorough cleaning of the head and block mating surfaces and an accurate check of trueness (Flatness) with no dips whatsoever. The block will be a problem since most folks are too lazy to pull the studs, clean them up and reseal and re-install them.

Posted: Sun Apr 30, 2023 1:57 pm

by JeepdaddyRC

Blown head gasket between #2 and #3 cylinders and to the water jacket.

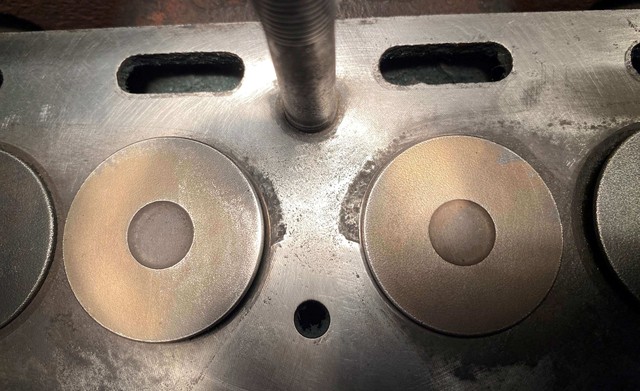

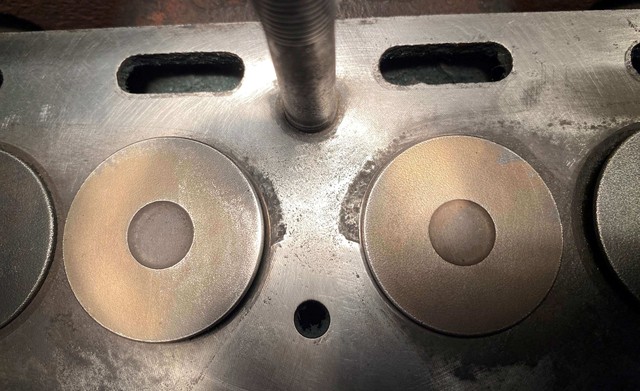

See pitting on block and adjacent edges of #2 and #3 exhaust valves where head gasket was blown.

The rest of the block, valves and pistons look ok. Machinist straight edge indicated block was flat. You can see the RMC serial number.

Is the pitting trouble?

[img]

Posted: Sun Apr 30, 2023 4:17 pm

by wesk

You will need to use a sealant with whatever head gasket you choose to use weather the gasket manufactures calls for sealant or not since the pitting provides the starting point for erosion which ends in gasket damage. It was your cylinder head that showed the worse pitting. I hope you had the head resurfaced when they did the block deck? Post a photo of the mating surface of your cylinder head now.

Posted: Sun Jun 04, 2023 8:06 pm

by JeepdaddyRC

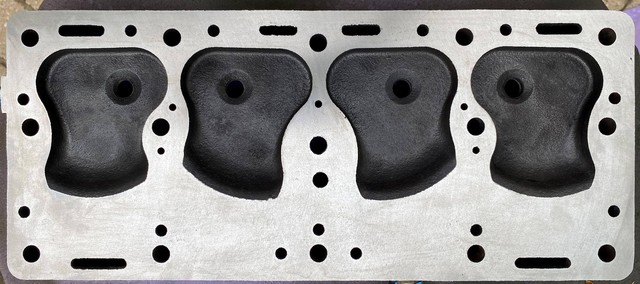

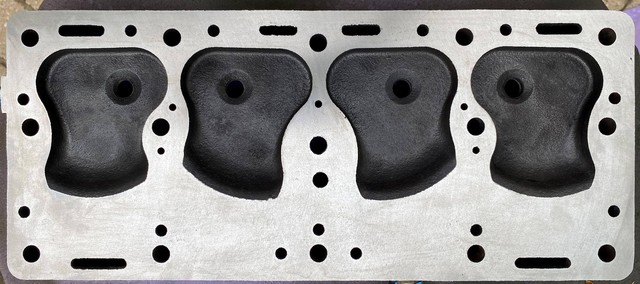

Important not to leave a thread hanging. Cylinder head back from machine shop. Head magnafluxed and decked. No cracks in head. Installed head with new copper sandwich gasket with sealant. Torqued to 60-65 ft lbs.

Repeat leakdown test confirmed no more leakage between adjacent cylinders, no more sound at carb or tailpipe, and coolant no longer pushed up in the radiator.

Still have a fuel delivery issue and will now return to that thread:

http://www.willysmjeeps.com/v2/modules. ... ic&t=13523

Posted: Mon Jun 05, 2023 2:38 am

by Pierre

Nice, how many thousands were taken off the head ?

Posted: Mon Jun 05, 2023 10:43 am

by JeepdaddyRC

I don't know the exact amount removed, but the old-school machinist knows the L-134 ands stated he took off as little as possible.

[img]

[img]