Page 1 of 1

Changing M38 motor mounts

Posted: Sun Nov 19, 2023 8:17 pm

by JeepdaddyRC

Thanks to RonD2 and Wes for seeing incorrect motor mounts.

Trying to decide if I can tackle this.

My research suggests the following steps are required:

drain coolant

remove grill

remove fan

lift radiator straight up off the support brackets

remove radiator support brackets from motor mounts (keep track of position)

disconnect flexible fuel line at fuel/vacuum pump

disconnect accelerator linkage

remove mount to frame motor mount bolts (2 each side)

raise engine with jack using wood under oil pan skid plate (hopefully high enough to wiggle old mount out and insert new mount)

replace mounts and correct ground strap

Any tips or strategies? Anything I left out?

Posted: Mon Nov 20, 2023 12:56 am

by wesk

You should have the folding grill? Makes it a bit easier. I have changed front mounts in the past without disconnecting all those items. With the folding grill you can lift the entire engine, radiator, tranny and transfer as a single unit. You can lift the radiator enough with it connected to it's hoses to free the engine support bars on each mount. As you slowly raise the entire assembly just observed carefully what items need disconnecting as you go and they reach their limits. This should give you a shorter list of disconnects. It is always best to use a hydraulic engine lift or rafter mounted chain hoist for the lifting. You are only lifting the engine the height of the side mount studs.

Posted: Mon Nov 20, 2023 6:40 am

by RonD2

TM9-8012, Paragraph 116.d.(3), page 126. Disconnect exhaust header pipe from exhaust manifold. The stock M38 exhaust system is mounted rigidly (without any rubber mounts) all the way from the manifold to the muffler. Don't want to bend or break anything. Suggest install a fresh gasket on reassembly with a dab of anti-seize compound on the nuts.

Paragraph 116.f.(3), page 130, loosen (or remove) the two nuts from the rear mounting support cushion to the cross-member. Don't want to tear the rubber mount or rip the studs out of it.

I'd watch it, but it shouldn't be necessary to disconnect the fuel line from the pump. There should be enough flex in it to do the job.

Shouldn't need to remove the grill. Just lean it forward on its hinges.

Also note that the 2 lower radiator support rods should be re-installed at the same time with the new mounts before the radiator is bolted down.

The rods can't be installed with the mounts and radiator both already bolted in place.

Install and adjust the new engine stay cable (1/2-inch up-down movement at mid-point).

On reassembly, inspect the clutch control lever ("z-bar") to ensure it didn't pop out of it's mounting sockets on the frame and transfer case (Paragraph 116.g.(1) on page 132).

I agree with Wes that if you have the capability, lifting the motor using the forward lifting eye (mounted on the head) would be preferred over a floor jack under the oil pan.

Before starting the job, I'd also recommend disconnecting the batteries, set the hand brake, and securely chock-block the wheels.

Posted: Mon Nov 20, 2023 11:11 am

by JeepdaddyRC

Great tips. Thank you.

Unfortunately, I don't have an overhead lift or engine hoist. I have a floor jack and Harbor Freight transmission jack.

I considered dropping the T-90 transmission and transfer case to address leaks and replace synchros this winter. With T-90 and TC down, it will be easier to raise the engine, but that sounds risky unless lifting from above.

Nice that the M38 was designed with a folding grill so the Army could remove the entire powerplant, and perhaps that is the best way to rebuild the T-90 and replace engine mounts. I'm not a mechanic, just an old enthusiast. Never pulled an engine and even though TM9-8012 describes the steps in detail, scares me a little.

Posted: Mon Nov 20, 2023 12:17 pm

by wesk

If you are concerned about the safety issues then do the lifting or removal with a friend present who has experience in lifting engines. Also there are plent of rental agencies that rent engine hoists and chain hoists.

Posted: Mon Nov 20, 2023 12:37 pm

by RonD2

If you can't borrow one, Sun Belt Rentals has engine hoists for $45 a day.

If you're also going to work on your transmission and transfer case the only way to go is to remove and replace the entire power pack as a unit.

Much safer, faster, and easier than wrestling with them under the jeep on the floor.

Rent the hoist one day to pull it and one day to install it --- total cost less than $100.

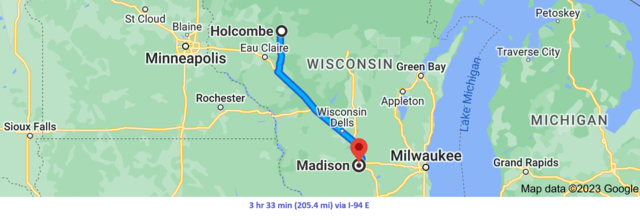

What's your location in Wisconsin?

Maybe you can sweet-talk Wes into making a house call.

Posted: Mon Nov 20, 2023 1:25 pm

by wesk

Posted: Mon Nov 20, 2023 3:27 pm

by JeepdaddyRC

The engine hoist sounds like the smartest play - just need to get over the intimidation of removing my first one.

Do you build a wood frame or dolly to set the powerplant on after removal? I have removed a few CJ transmissions and a GPW transmission using a tranny jack from underneath. But getting harder to lay on that cold floor as I age.

House call?! That's a good one. While a visit from Wes would be a real honor, as well as fun and educational, Wes probably has plenty to do. I do hope to visit him sometime on my travels north - and take him something for all the helpful support and advice over the years. I couldn't have come this far without the help of Wes, RonD2 and this great forum.

Posted: Mon Nov 20, 2023 4:40 pm

by wesk

Engine stands are readily available used or new. Just google "Engine Stands For Sale" . They start around $49 and go as high as $200.

I have two of these and they do come in handy. In your case you can pull the entire power plant (Radiator/engine/tranny/transfer) then set the whole thing on the floor on top of a pair of old tires. Then unbolt the engine from the Bell Housing. Now lift the engine from the front hump on the lifting bar and bolt the rear of the block to the engine stand. Now roll the hoist back over to the bell/tranny/transfer group laying on the tire. Hoist it up and bolt the bell housing to the 2nd engine stand. Voila, the rest of your work can be done with the satnd rolled up next to your bench and you working on it as it sets in front of you waist high.

Used on Ebay for $50.

https://i.ebayimg.com/images/g/oKsAAOSw ... -l1600.jpg

Here's another for $25

https://www.ebay.com/itm/404572846510?h ... R5T0hu79Yg

Posted: Tue Nov 21, 2023 12:32 pm

by 4x4M38

Isnt the forward position on the lift bracket for engine only and the rear for the assembly Ron?

Posted: Tue Nov 21, 2023 12:54 pm

by wesk

Yes the forward is for completely removing engine only and the rear is for removing entire power plant assembly. However when only wishing to change the front engine mounts the standard practice is to loosen all mounts, and slowly lift while carefully observing strain points and relieving them as you go until the front is high enough to allow removal and installation of the front engine mounts and radiator bars.

Posted: Tue Nov 21, 2023 10:20 pm

by 4x4M38

Thanks Wes.