Page 1 of 1

Zerks causing trouble.

Posted: Thu Apr 18, 2024 8:17 am

by horse

Hi, Just been greasing all the Zerks or grease nipples as we Brits call them.

Only ones I can't get to are on the GKN front Prop Shaft. They are not pointing in the correct direction to get the grease gun in.

Would this be an installation problem? What would be the best way to rectify the situation?

Horse.

Posted: Thu Apr 18, 2024 9:34 am

by wesk

Hello Horse,

I assume you are referring to the aftermarket drive shafts produced by GKN. I found none listed in their USA listing for jeeps CJ or M series and I found the UK listing only covers CJ5 66-on with 167 variations of shafts. So I doubt we can help without seeing detailed photos of your installation.

Posted: Thu Apr 18, 2024 9:45 am

by RonD2

Posted: Thu Apr 18, 2024 10:53 am

by horse

Thank you to you both.

The front Drive Shaft came with the Jeep and looks like the video clip but not pointing backwards.

I did not realise it was an aftermarket one, the rear Is a Spicer.

I will take it off and see if I can improve the position but would like the correct one on it so will be looking out for the correct type in the future.

Horse

Posted: Thu Apr 18, 2024 8:19 pm

by wesk

Photos would help tremendously. It is not easy for us to imagine what you are describing. Especially with a shaft that operates thru varying angles as it rotates. If you are not lifting the jeep off the floor then just jack one tire off and the floor, put the transfer in neutral and rotate the free tire to reposition the drive shaft.

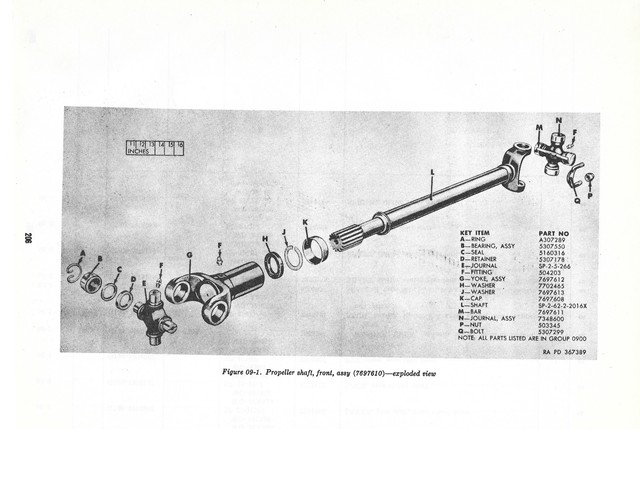

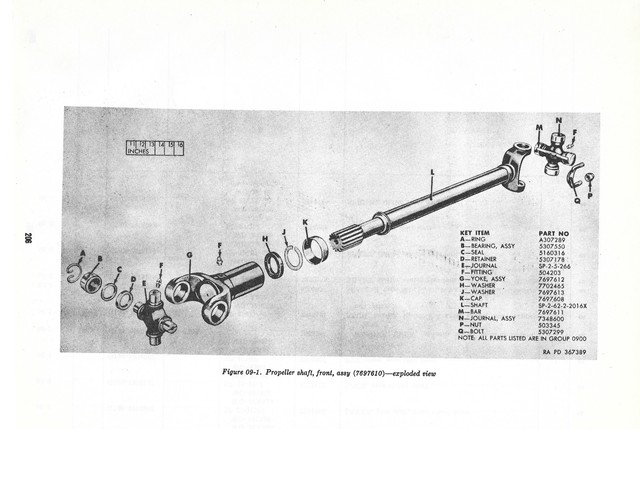

This is the stock arrangement

Posted: Fri Apr 19, 2024 1:07 am

by horse

Hi Wes.

I am trying again with this Mac computer to put a photo up.

I have the Jeep off the ground and have rotated the prop as you say.

The Zerk is only just out of line but not enough room to place the grease gun on.

At no point in the rotation of the prop does the angle allow the grease gun in.

See how I get on with the photos.

Horse.

Posted: Fri Apr 19, 2024 3:39 am

by horse

I have looked again and the Zerk is pointing forward.

May be if I take the spider off and turn it around it may line up better?

Horse.

Posted: Fri Apr 19, 2024 11:39 am

by RonD2

horse wrote:Maybe if I take the spider off and turn it around it may line up better?

Exactly!

That was the point of the video I suggested.

Posted: Fri Apr 19, 2024 12:04 pm

by horse

Thanks, took a bit of knocking in but I know what to do now.

Horse

Posted: Sat Apr 20, 2024 3:11 pm

by wesk

Horse, Here's your photo and the results of our PM.

The needle fitting adapter can be used to service your joint without disassembly and reversing of spider.

Posted: Sat Apr 20, 2024 3:32 pm

by RonD2

Looks backwards to me.

Posted: Sat Apr 20, 2024 3:43 pm

by horse

Thanks Wes for putting up the photo, nice and clear.

I did not know about the Needle fitting adapter, very useful.

By dropping the front of the shaft I was able to open the joints enough to get the grease gun in. I held the loose caps in place with a clamp to stop the pressure forcing them off. Next time I will have the adapter.

Thanks Horse.