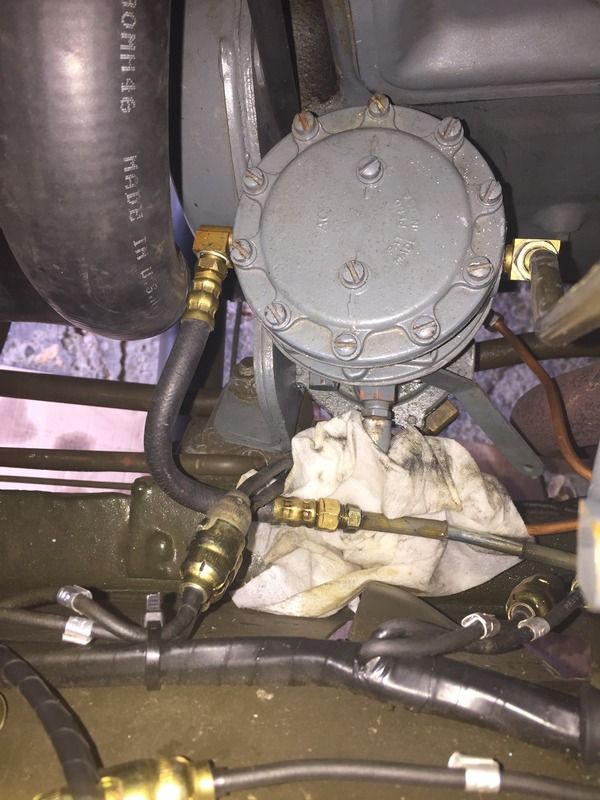

If you are asking the shops to duplicate that Omix-Ada hose that may be the problem. They may not have those specific fittings available.

Bring them your 90 deg nipple off your fuel pump and the tube that runs from the hose to the shutoff valve. Tell them to make you a hose that length that will fit your nipple and the inverted flare nut on your tube.

This is the spec for the proper hose:

33H127-60

Nonmetallic Hose; Rubber synthetic tube

33H12760

Specifications

For Use With/On: Grumman a10 aircraft AGAV

Burst Test Pressure: 1250.0 pounds per square inch single response CQBD

Cross-sectional Shape Style: Round AAGR

Hydrostatic Test Pressure: 400.0 pounds per square inch single response CRDW

Material: Rubber synthetic tube MATT

Maximum Operating Pressure: 200.0 pounds per square inch single response CQGM

Media For Which Designed: Fuel/oil, hydrocarbon single response MEDA

Minimum Inside Bending Radius: 4.000 inches ACKH

Nondefinitive Spec/std Data: 4 size ZZZT

Outer Covering Environmental Protection: Abrasion resistant and hydraulic solution resistant and oil resistant CRJM

Outside Diameter: 0.469 inches nominal ABKV

Inside Diameter: 0.250 inches nominal AARX

Inside Surface Condition: Smooth CRWL

Layer Composition And Location: 1st layer braided cotton cord err-100 CQCS

Layer Composition And Location: Outer layer molded rubber, synthetic err-100 CQCS

Specification/standard Data: 81349-mil-h-5593 government specification ZZZK

Temp Rating: -65.0 deg fahrenheit single response and 160.0 deg fahrenheit single response ABJH

Vacuum In Torr: 254.0 CRSM

Federal Supply Class (FSC): Hose And Flexible Tubing

National Stock Number (NSN): 4720-00-540-1962

_____________________________________________________________

The adapters are Aeroquip:

Male inverted flare is PN 4740-4 or AEQ4740-4

Female inverted flare PN 4743-4 or AEQ4743-4

Here's a link to a catalog page that will help

https://www.greggdistributors.ca/pdfs/CatV001.pdf